2 4 0 T U R B O . C O M

|

||||||||||||||||||||||||||||||||||||||||||||||||||

|

||

| G80 in a 240 |

G80 Mods |

|

| Diff VSS Sensors |

Other Misc Rear End Stuff |

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

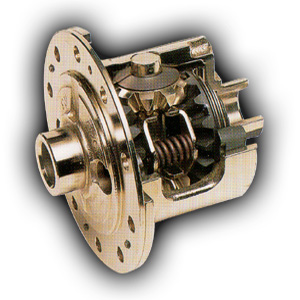

| Here are some videos from Eaton explaining how this

differential works: https://www.youtube.com/watch?v=tTGZOJQQBeE |

||||||

| https://www.youtube.com/watch?v=ftyJvIO0DZ8 | ||||||

|

|

||||||

|

||||||

|

|

||||||

|

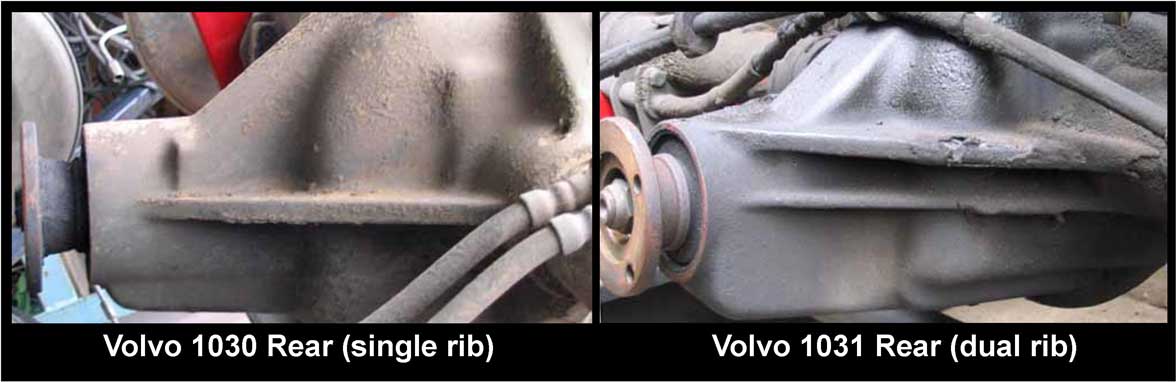

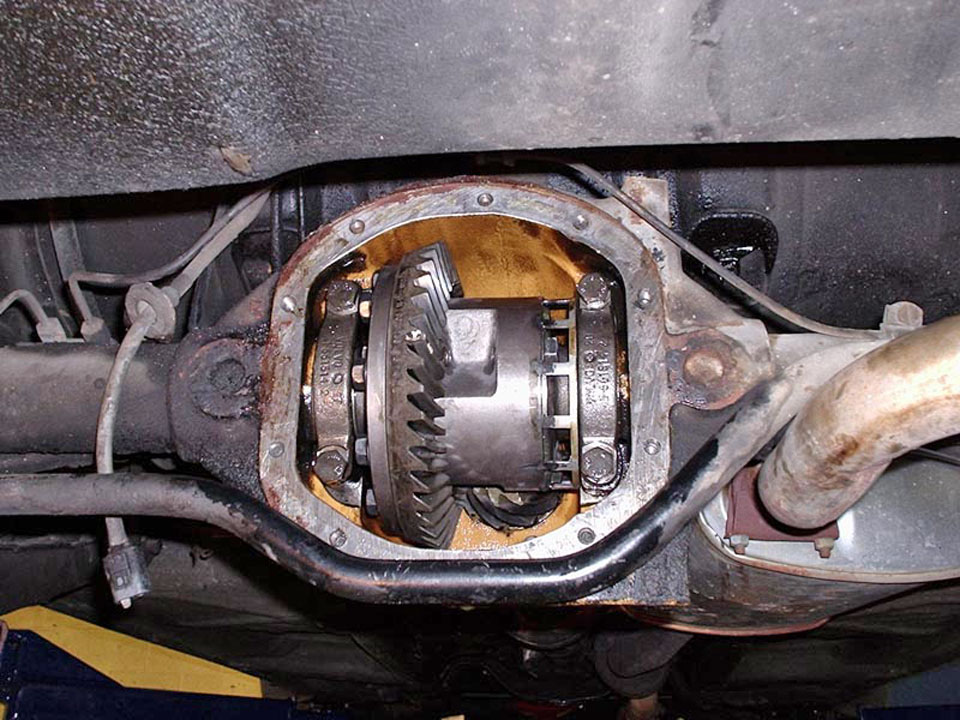

If you intend to install a used G80 differential in a 240, it's a direct (or

nearly a direct) bolt-in to any 240 Dana 30 rear end (Volvo 1030, 1031 and

1041). In most cases, the G80 differential will bolt in and it can be run with no adjustments, even without replacing any bearings or shims. You MUST remove and reuse your own ring gear, which matches your existing pinion gear, unless you plan to change both of those. Always install the RING and PINION GEARS as a matched set.

If you're concerned about installing a used G80 diff "AS IS" with no changes, you can take an extra step by also checking the ring gear backlash after installing. This is done using a dial caliper. Backlash is the amount of rotational movement (back and forth) of the ring gear when the pinion gear is stationary. The Volvo specification calls for around .005 to .007 inch (5 to 7 thousands of an inch) of backlash. There are how-to videos on YouTube for checking ring gear backlash on a rear end. If the backlash is out of spec, the rear end may whine at some speeds or there may be some unusual wear over time. CORRECTING EXCESSIVE BACKLASH: There are shims under the carrier bearings, which can be added or removed. This will adjust the ring gear closer to the pinion gear (which will reduce backlash) or farther from the pinion gear (to increase backlash). Removing bearings and changing shims will of course increase the difficulty of this installation, because these bearings are pressed on. It can be difficult to remove these bearings without damaging them and some will tell you the quickest removal is cutting them off. I don't think that is necessary. REMOVING A VOLVO CARRIER BEARING WITH A BEARING PULLER (Carrier Bearing: AKA Differential Side Bearing) So far I have avoided having to deal with removing or replacing any carrier bearings on two different G80 installations in my 240s. In each case I have simply installed the G80 in my car with the bearings and races that came with the G80 from the donor car. I have not removed the bearings from a donor G80 yet. If you find yourself needing to change, pull or adjust bearings, here's a little info below that may help. | ||||||

| Reportedly, if you have the correct VOLVO BEARING PULLER TOOL (shown here), then pulling these bearings can allegedly be done without damaging them. Without this tool, it is reportedly much more difficult to remove these bearings without damage. If you damage them, this means you'll need new bearings.

More information: https://turbobricks.com/index.php?threads/g80-240-install.317970/page-2 |

||||||

|

I have not personally experienced this MATCO puller tool, but it looks pretty good in the below videos:

Have a look at this video showing a carrier bearing puller made by Matco (Part Number MST4520), which appears to be doing very well on a carrier bearing:

And here's the OTC version (PN 4520), which looks identical to the Matco:

https://www.youtube.com/watch?v=-eh8WF_ON6g |

||||||

|

|

||||||

| G80 DIY BOLT-IN INSTALLATION NOTES There are some people who will tell you that the only "correct" way is to fit the differential just as you would a brand new differential replacement, using new bearings, shims and a professional technician. This, of course, can be VERY expensive and if it's too expensive to try a G80, then there's just no point. The choice is yours, however many DIY "junkyard" mechanics (myself included) have already done this successfully as (*nearly) a simple bolt-in. *Regarding the "nearly" a bolt-in thing: The one exception I have found is for 1991 and older 240s. See the info below on trimming the right side axle. |

||||||

|

See that round silver metal disc below?  I've seen this plate referred as an "oil slinger" or a "crown wheel screw lock plate" (supposedly to prevent ring bolts from loosening on limited slip differentials). You'll almost never see this plate in a photo of a removed G80 or a retrofitted one, because they're almost never re-used. That plate is found on all Volvo G80 differentials that were originally installed in Volvos. This plate covers the ring gear bolts. It will prevent you from removing the ring gear bolts unless the bearing on that side is removed. If you don't plan to remove this bearing and you need that plate gone, you can simply cut the plate off with tin snips and toss it. This is the method used most often. This way you can swap your ring gear without having to mess with pulling and installing new bearings.

Here's a YouTube video of

someone pulling a G80

from a Volvo at a salvage yard and you can see

this disc

on that differential: https://www.youtube.com/watch?v=wwQh9mMtmvE SALVAGE YARD NOTE: If

you remove a G80 from a salvage yard car yourself, make sure you save the bearing races and mark

them RIGHT and LEFT with a marker so they end up on the same side as

they were installed originally.

|

||||||

|

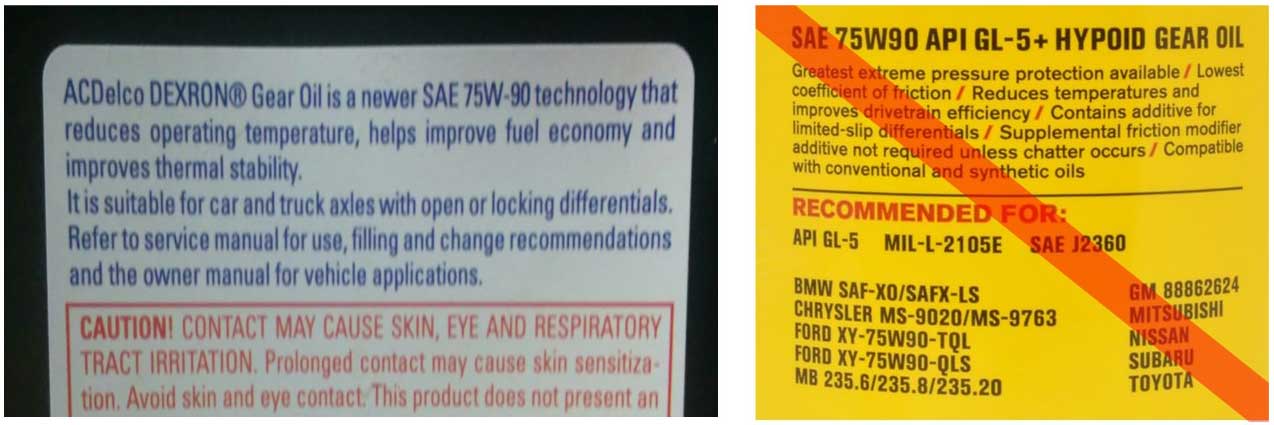

BUYING A USED G80

If you're shopping for a used G80, keep in mind that this differential was used in a lot of different cars and trucks. Some (non-Volvo units) have different axle spline counts. The G80 used in Volvo cars was installed in a Dana 30 (1041 axle) with 27 spline axles. All such G80 differentials from a Volvo it should have "VOLVO" and a Volvo part number stamped into it as shown above. The part numbers seem to be pretty various and seem to have changed a number of times over the years.

Here's an example of one for sale with one of the bearings removed and missing. This would need new bearings. It's ok if you plan for that or if you're having a professional install it.  Here's an example below of one which still has the two carrier bearings installed and the bearing races are included. It's ready for you to install your own ring gear and then install in the rear end yourself.   |

||||||

|

|

||||||

|

TRIMMING THE 240 RIGHT SIDE AXLE:

This is the part of a G80 installation that makes the difference between nearly a bolt-in or a 100% bolt-in. If your rear end is from a 1991 or older 240, you will need to trim a small amount off of the inner end of the RIGHT side axle. This is because the right axle in that 240 is a bit too long to fit all the way back in with the G80 in place. The amount that needs to be trimmed is about 1/8 to 1/4 inch. In these photos you can see where I trimmed 1/4 inch off of my right axle. A high-speed cut-off wheel took care of this easily in a few minutes.  LATER 240 AXLE CHANGE: Sometime in 1992 the 240 axle was changed so that the right side axle was made slightly shorter from the factory. This means that some 1992 and ALL 1993 240 models will not need any axle trimming and this installation will be a 100% bolt-in for these late 240s. |

||||||

|

||||||

|

|

||||||

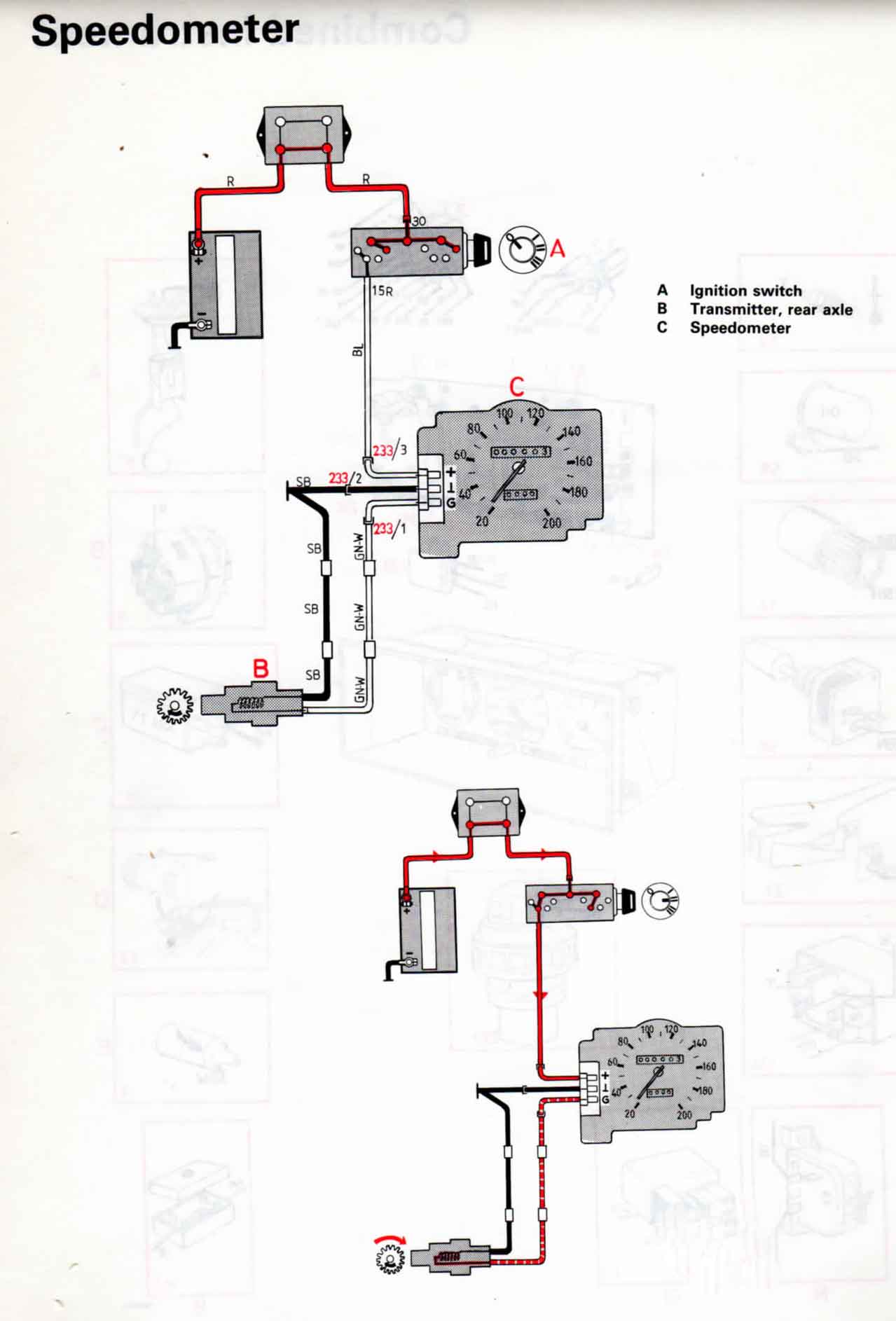

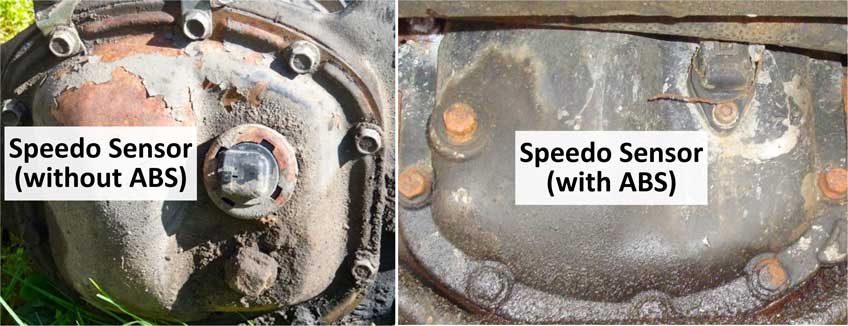

| SENSORS and TONE RINGS All related to 240s with Electronic Speedometers (1986-93). |

||||||

1986 and later 240s came with electronic speedometers which were triggered by a vehicle speed sensor (VSS) in the rear differential cover. There were two types of VSS: Non-ABS or ABS type. 1986-1992 240 without ABS (below left). 1991-92 240 with optional ABS (below right). 1993 240, ABS was standard (below right). |

||||||

Above O-RING replacement Volvo PN 974673. SIZE: 0.063 inch (1.6 mm) cross section. 0.819 inch (20.8 mm) inner diameter.  |

||||||

|

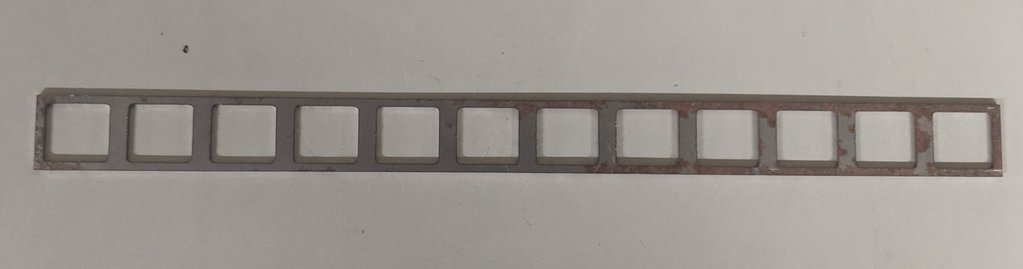

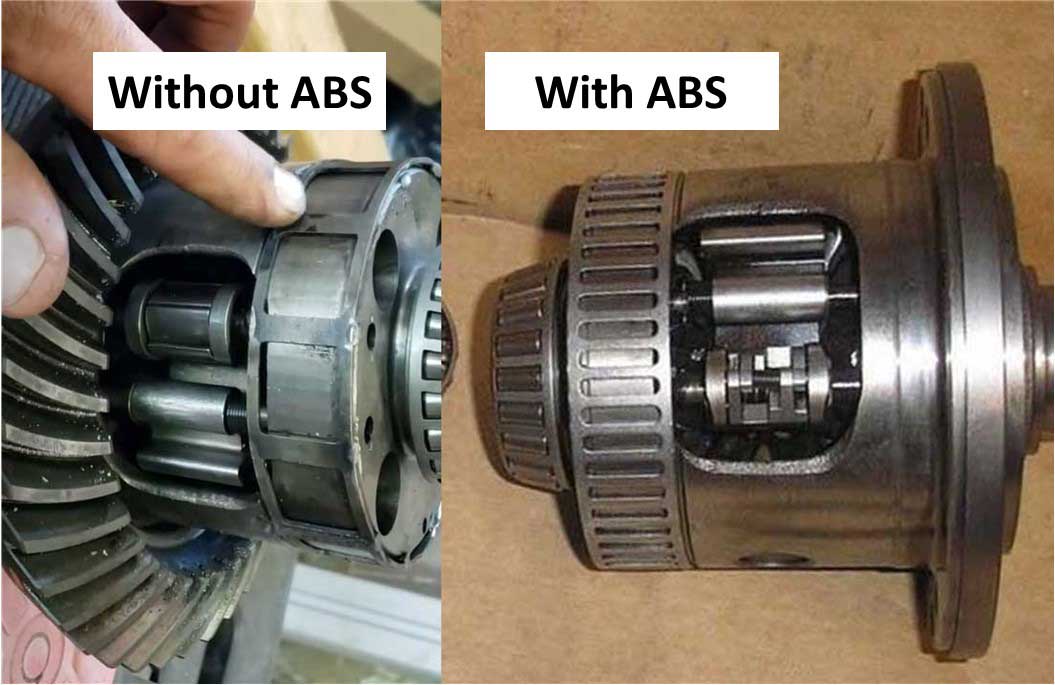

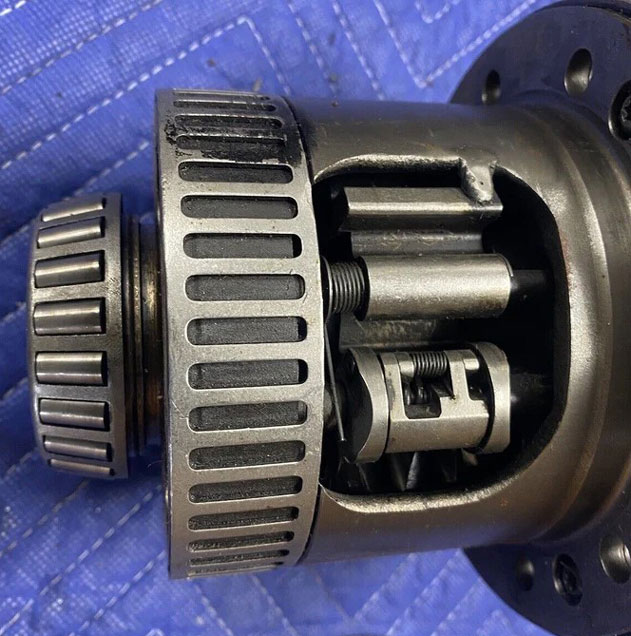

TONE RINGS If your G80 came with a 48 tooth tone ring (standard for all ABS equipped Volvos) and your electronic speedo 240 uses a 12 tooth tone ring (standard for NON-ABS 240s), your speedometer will not work correctly. Some DIY installers have successfully modified the 48 tooth tone ring using a Dremel cut-off wheel to created a 12 tooth ring. Keep in mind that you should then probably use the sensor that works for the 12 tooth ring. And if you installed a newer aluminum differential cover from a later car, the earlier sensor might have fitment issues. For such a custom installation, some sensors may be adjustable for depth and some may need shims added or subtracted to adjust depth.

Check your clearance with a feeler gauge through the

filler hole. Turn the pinion as you do so to check

clearance. Start with a thin gauge and go thicker until you can feel the rotating tone ring.

(Source: https://turbobricks.com/index.php?threads/yet-another-g80-into-a-240-thread.204882/) |

||||||

|

||||||

|

|

||||||

G80 INTERNAL MODIFICATIONS:

|

||||||

If you decide you want to modify your G80 or buy one that's been modded, this mod can be

done by a couple different methods and these are

outlined below. Not all of the methods are the

same.

A modification to a G80 is intended to change the way the the internal locking mechanism works when driving. Altering the internal mechanism can be done to make it stay locked through higher speeds or to even stay locked at all speeds. But at least one person says Even an unmodified G80 will stay locked at much higher speeds than 25 as long as the power is continually applied or increased. Stock units can stay locked up until at least 60 mph in turbo cars." (Source: https://turbobricks.com/index.php?threads/g80-locker-a-few-questions-for-those-who-have-modded-one.240436/ I agree with this statement and it's what I have found with my unmodified G80. This image below shows a centrifugal pawl that was welded to the case to keep it from moving. This will keep the locking mechanism LOCKED at all times.  These images below will show a centrifugal pawl that was removed, cut and reinstalled without the counterweight. This is intended to still allow the pawl to move outward at high speed, which will then let the differential unlock.  An old article from 2004 and this modification in Turbobricks: https://turbobricks.com/index.php?threads/g80-locker-mod.25829/ More resources below. |

||||||

| Below Video:

Disassembling and Modifying a G80 https://www.youtube.com/watch?v=zXgTWLP_e-I |

||||||

| MORE HELPFUL ARTICLES

AND DISCUSSION LINKS: https://turbobricks.com/index.php?threads/couple-g80-swap-questions.338768/ https://turbobricks.com/index.php?threads/simple-locker-mod-g80.321262/ http://retrorides.proboards.com/thread/150384/volvo-series-locker-diffs-eaton http://www.autoevolution.com/news/a-simple-guide-to-the-g80-locking-differential-94874.html https://www.youtube.com/watch?v=xevx06aay7E |

||||||

|

| Here's a video on DIY replacing a leaking 240 pinion seal. https://www.youtube.com/watch?v=eoIV0gkHqBI |

I have left it up at the request of users for the sake of the info it contains. I hope it helps. |