2 4 0 T U R B O . C O M

D A V E ' S V O L V O P A G E

| 4-Speed Cooling Fan

Controller Project and Diagrams |

|

UPDATED: January 12, 2024 CONTACT

|

D O M

A I N S   |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

THIS IS OLD INFO. I NO LONGER USE THIS CONTROLLER, BUT I'LL LEAVE THIS PAGE UP FOR REFERENCE.

I am NOT offering fans, controllers or harnesses for sale here. You may use this info to build your own if you like.

Before I published this page I began a forum discussion about this project, which you can find here.

|

INTRODUCTION

I began this project in summer 2016 out of frustration. I had experienced successive failures of a number of ready made fan controllers over the years (Delta Current Control and Flexalite), partly because I was using a high-amp Ford fan. So this project gave me a challenge to see if I could build something BETTER on my own that would do TWO THINGS:

But then . . . . .  In 2018 I discovered this line of high-amp PWM fan controllers. So I tried one and then retired my home-made 4-speed controller. This new controller was flawless for years until I tried something new again. CLICK HERE TO SEE MY INSTALLATION OF THIS NEW PWM CONTROLLER. |

|

|

|

|

So as you may have noticed, I'm using a Lincoln Mark

VIII fan and shroud (1997 model)

mounted on a large 26 inch wide Griffin aluminum

radiator. I decided to try building my own

fan controller using simple, reliable relays to see if I could

make it work the way I wanted and I wanted one

that would LAST.

There are people who will warn you that using relays is risky, since relays can be slowly damaged from turning on high-current motors over and over. This may be true, but It's my opinion that it would takes years and I doubt the damage would come anywhere close to having a high-tech controller meltdown every 1.5 to 2 years! More general info on

the installation of my Mark VIII fan and Griffin

radiator in my Volvo 242 Turbo can be found in my

Cooling Fan

Project Page at:

https://www.240turbo.com/ElectricCoolingFans.html#markVIIIfan |

|

|

Your feedback

is appreciated.

If you have any questions or comments or if you decide to use this info to build something like this for yourself, I would like to hear from you. |

|

Here's

the

4-Speed Successive Relay Function Theory

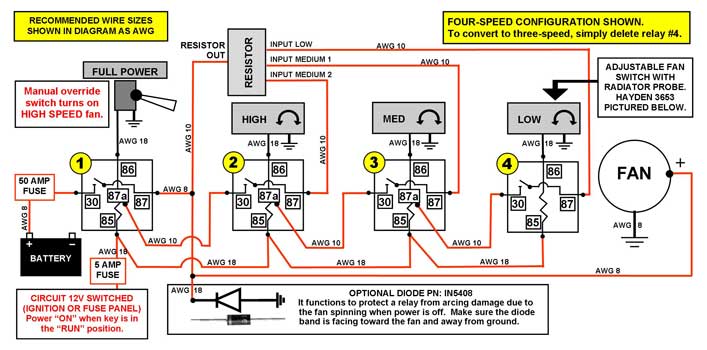

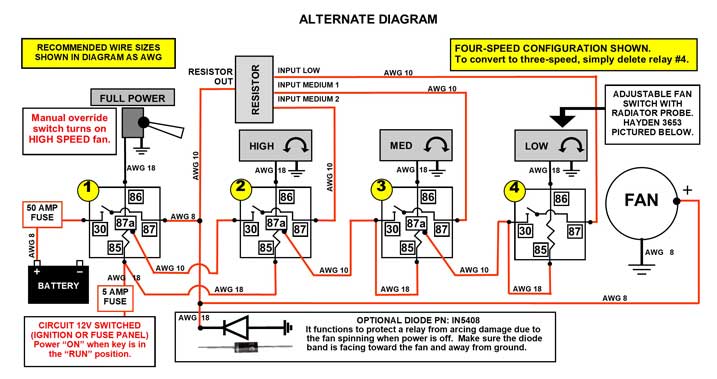

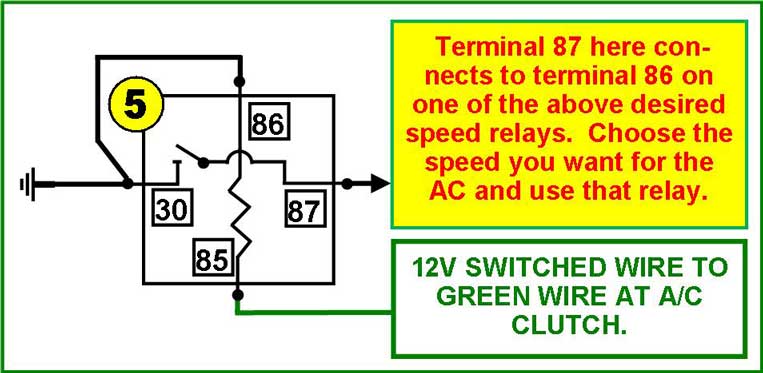

There are TWO different diagrams above.

Either will perform the same function. You may

refer to them as I explain how this is done

below.

I designed this to allow the cooling fan to remain

OFF until your low temp set point is reached and

the sensor activates power to the low speed relay

(Relay 4).

Since this low speed circuit will only allow a low

amperage current value, it starts the fan slowly and softly, without

the heavy drag you would get normally from

starting a high-current motor. This low

speed can be used to maintain cooling at idle with

minimum fan use, but this would depend on the fan

speed chosen for the low speed. There are a few

choices. When your temperature climbs a little higher, the SECOND sensor will activate the next relay (Relay 3), automatically cutting power from the lower speed relay (Relay 4). This way only ONE CIRCUIT will be powering the fan at a time. This

successive function works for each relay to

increase fan speed as temperatures rise.

|

|

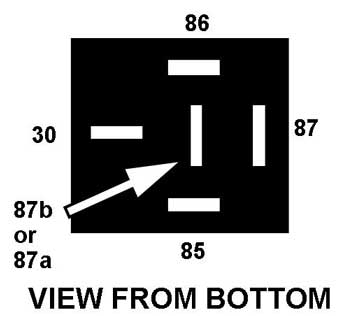

SPST vs SPDT

Relays. What’s the difference?

Single Pole, Single Throw (SPST): This relay will be

identified as having a middle 87b spade (or

sometimes no middle spade at all). This is the

most common relay used for fog lights or other

simple circuits. If there is a middle 87b pin, that

pin will have power whenever there is power to the

87 pin. This way the middle 87b pin may simply

be used as an extra power output.Single Pole, Double Throw (SPDT): If you have a relay with an 87a pin in the middle, it's an SPDT relay, also called a "changeover" relay. In a changeover relay, the 87a pin will be “HOT” anytime the 87 pin is "OFF," so long as the relay is connected to power. So when 87 is "OFF", 87a will be "ON". When 87 turns "ON", 87a will turn "OFF". |

|

||||||||||||||||||||||

|

|

||||||||||||||||||||||

| TEST #1 BENCH TESTING This first test was done with the engine OFF, so the battery voltage was not as high as it would be if the engine was running. Lincoln Mark VIII Fan Speed/Current Testing (using static 12.7v battery voltage with engine off) Dorman 973-018 4-speed resistor pinout shown below. |

||||||||||||||||||||||

My first surprise was seeing how the resistor HIGH circuit (through Relay 2) produced a number so much lower than 100%. That 77% figure was not a disappointment at all, since it offered an opportunity for an extra speed choice below 100%. Using fan speed figures like this, you can decide which circuits or resistors you want to use for the fan speeds you like. That low 26% speed might sound ok on paper for a low speed, but once I saw how slow that actually ran the fan, I felt differently. It was too slow for my use. You can see in my diagram up near the top of the page I had originally listed this 26% for my LOW speed. The reality was that it was too low on my car with an intercooler and AC condenser blocking the radiator. So I decided to use the 36% speed as my LOW speed instead. That 26% low speed might work for a car without an intercooler and AC condenser blocking the radiator. Every car is different. |

||||||||||||||||||||||

| TEST

#2 INSTALLED AND RUNNING Another test was done after the full installation of the completed controller. Using running battery voltage (voltage readings below). Since the 26% low speed was not used, it was not measured here. I have a 188 degree Fahrenheit coolant thermostat in the engine and the 36% speed seemed to do very well to keep things nice and cool at idle on a warm 85 degree day. If the climate is warmer, then the medium 55% speed may come on occasionally. Keep in mind that every car is different. My car has a very large aftermarket AC condenser (with dual fans) and an intercooler in front of the radiator. Those items obstruct the flow of air to the radiator a lot when compared to car without those items.

|

||||||||||||||||||

FINAL

SPEED

SETTINGS CHOSEN FOR THIS PROJECT

|

||||||||||||||||||

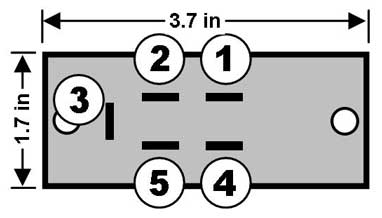

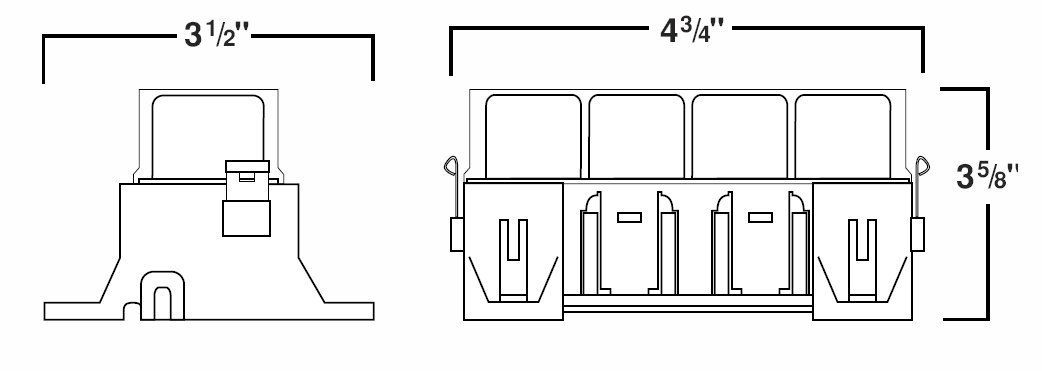

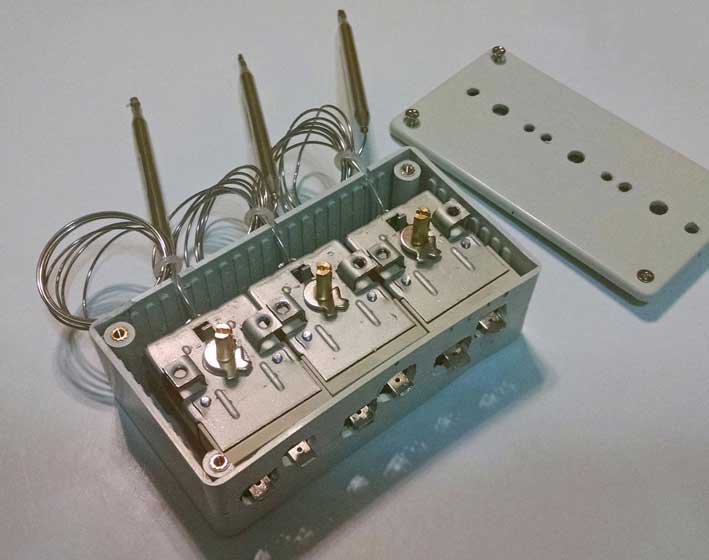

Optional Items Hella H84988001 Four

Relay Sealed Box. Available on-line for

about $40 to $50. Pricey, yes! If you're

concerned about moisture messing with relays or

maybe you just want them to look nicer, this may

be a solution. Keep

in mind this box is NOT waterproof.

There is an o-ring sealed lid, but the bottom is

not sealed at all. NOTE: The

high-current 80A (full-power) relay will NOT fit

in this box, since it uses a couple .375 inch

terminals instead of all small .250 inch terminals

like standard relays. This

box holds only standard relays. The 90

degree mounting ears are removeable and supposedly

you can connect two or more of these boxes

together side by side. Hella H84988001 Four

Relay Sealed Box. Available on-line for

about $40 to $50. Pricey, yes! If you're

concerned about moisture messing with relays or

maybe you just want them to look nicer, this may

be a solution. Keep

in mind this box is NOT waterproof.

There is an o-ring sealed lid, but the bottom is

not sealed at all. NOTE: The

high-current 80A (full-power) relay will NOT fit

in this box, since it uses a couple .375 inch

terminals instead of all small .250 inch terminals

like standard relays. This

box holds only standard relays. The 90

degree mounting ears are removeable and supposedly

you can connect two or more of these boxes

together side by side. |

|

|

I found an ABS

project box to fit the three Hayden sensors and to

help make this installation look nicer. There

are a lot of sizes out there for boxes in a couple

colors, including black. This box is 4.7 inches long x 2.6

inches wide x 1.4 inches tall O.D. (found

on Amazon). I had to do some grinding on the

inside to make everything fit inside. A larger box

would have been easier, but I wanted it as compact

as possible. Cost was about $6.00. The box was

painted black before completion. I found an ABS

project box to fit the three Hayden sensors and to

help make this installation look nicer. There

are a lot of sizes out there for boxes in a couple

colors, including black. This box is 4.7 inches long x 2.6

inches wide x 1.4 inches tall O.D. (found

on Amazon). I had to do some grinding on the

inside to make everything fit inside. A larger box

would have been easier, but I wanted it as compact

as possible. Cost was about $6.00. The box was

painted black before completion.Since doing this I found a better sized box that I probably would have chosen instead: >>> https://www.polycase.com/lp-55p. Its dimensions are 5 x 3.5 x 1.5 inches (127 x 88.9 x 38.1 mm). It would likely have been a better fit and I think with little or no cutting and carving. |

|

|

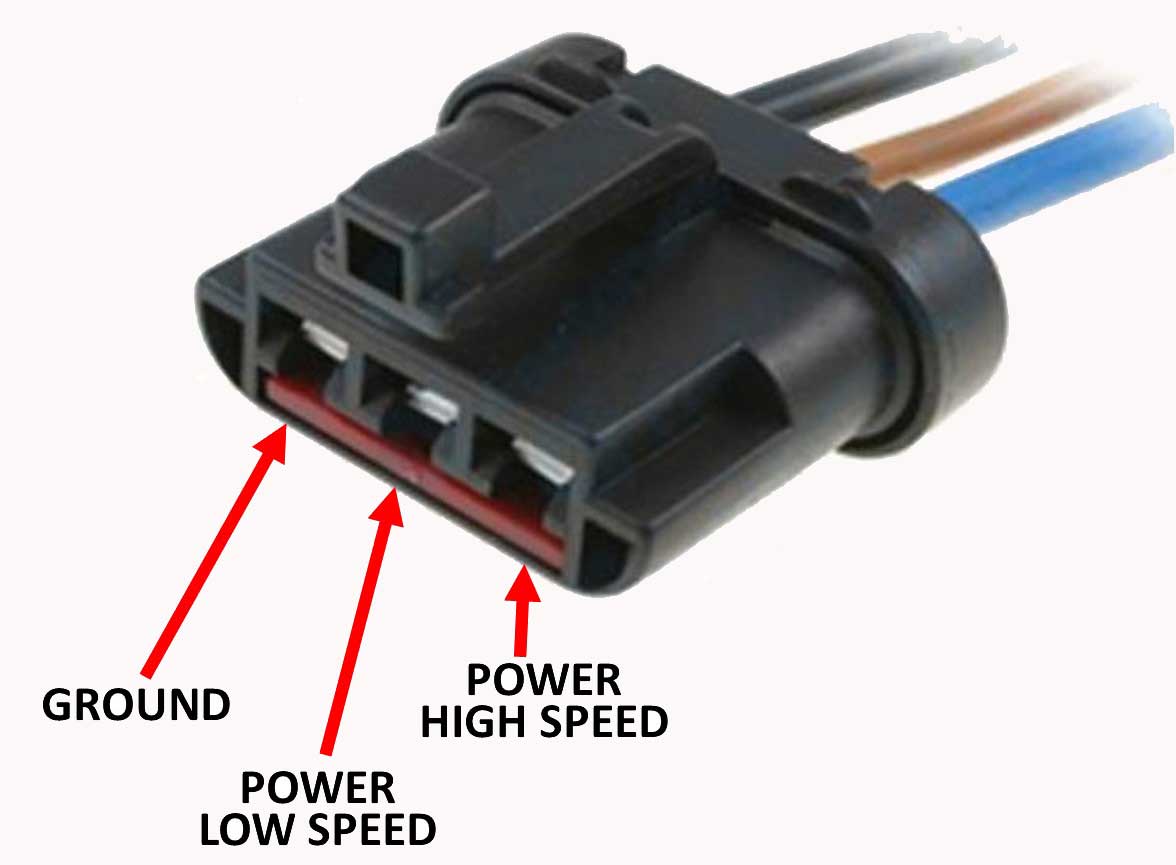

<<<

Ford Fan

Motor Connector. Fits a variety of

Ford/Lincoln/Mercury fans, including the Mark VIII

fan I have. A google search will find them in a

few places. I have only found them available with

12 gauge wire pigtails. In my opinion that's

a bit small for such a fan. I 'm using 8

gauge welding cable. <<<

Ford Fan

Motor Connector. Fits a variety of

Ford/Lincoln/Mercury fans, including the Mark VIII

fan I have. A google search will find them in a

few places. I have only found them available with

12 gauge wire pigtails. In my opinion that's

a bit small for such a fan. I 'm using 8

gauge welding cable. |

|

|

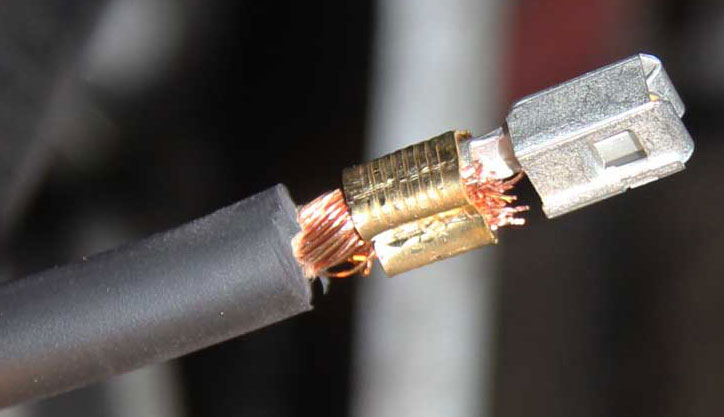

<<< Dorman

Conduct-Tite Terminal, AKA: Ford

Standard Block Technician Terminal. This is the

type of terminal that goes into the Ford fan motor

connector. Dorman offers PN 85367 which fits 14-16

gauge wire and is available on line. <<< Dorman

Conduct-Tite Terminal, AKA: Ford

Standard Block Technician Terminal. This is the

type of terminal that goes into the Ford fan motor

connector. Dorman offers PN 85367 which fits 14-16

gauge wire and is available on line. A 10-12 gauge version would be more appropriate, however so far it has NOT been found. If anyone can help with any real sources, please contact me. |

|

|

<<< So I improvised and

successfully used the 14-16 gauge terminals since

I couldn't find larger ones. I added one of my large

terminal overcrimps to make a solid crimp over

the 8 gauge cable I used.

Inserting this into the back of the Ford

connector housing can be a little tight. I

opened up the holes on the back of the connector

to accommodate this fat cable. If

necessary, a little trimming of the inside of

the housing with a hobby knife will help it go

in and click. Mine went in and clicked in

place without an issue. <<< So I improvised and

successfully used the 14-16 gauge terminals since

I couldn't find larger ones. I added one of my large

terminal overcrimps to make a solid crimp over

the 8 gauge cable I used.

Inserting this into the back of the Ford

connector housing can be a little tight. I

opened up the holes on the back of the connector

to accommodate this fat cable. If

necessary, a little trimming of the inside of

the housing with a hobby knife will help it go

in and click. Mine went in and clicked in

place without an issue. |

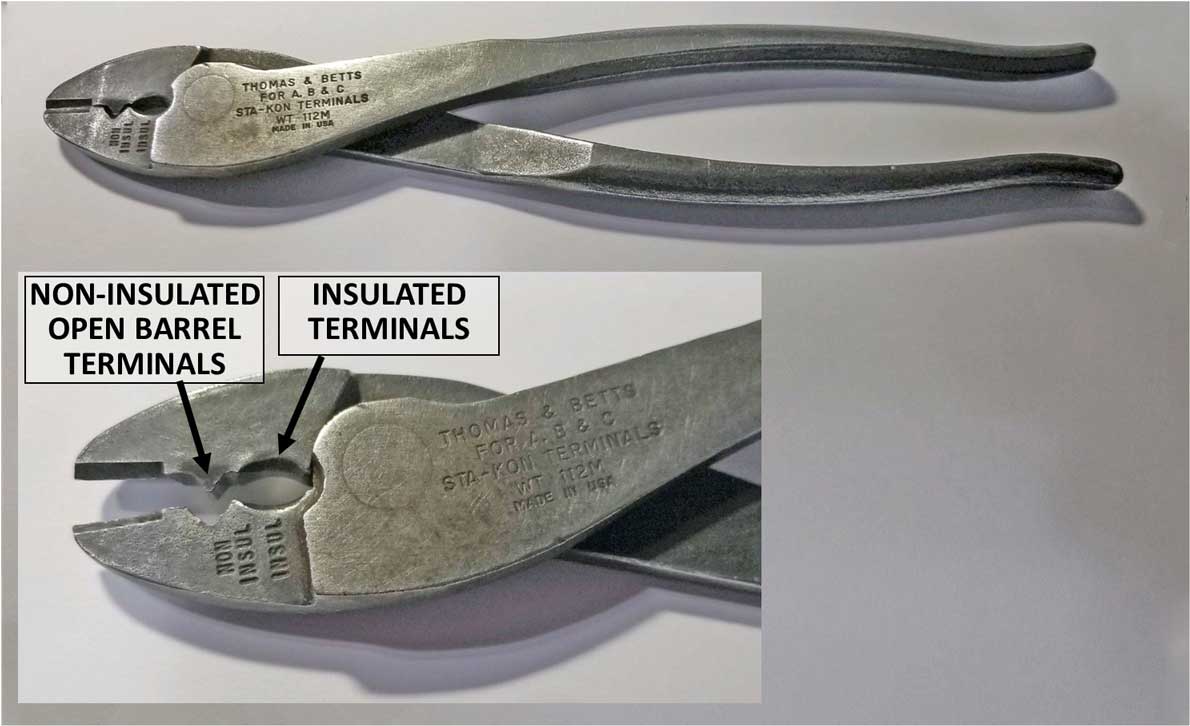

<<<

PROPER

CRIMP tools are important. Try not to use too cheap a

crimper or the wrong type for the terminal

you're using. Buy yourself something at

least as good as this one.

<<<

PROPER

CRIMP tools are important. Try not to use too cheap a

crimper or the wrong type for the terminal

you're using. Buy yourself something at

least as good as this one. For those of you who are curious about what crimper I use, this is it for 90% of my crimps for non-insulated (and many insulated) open barrel terminals. Thomas & Betts model WT 112M. It runs about $45. I've had this one for 20 plus years. With some

practice, this simple tool can create nice

crimps just like a fancy tool.

|

<<<

For a tool

that's a bit more fancy, look for a ratcheting

crimper that will do open barrel F type terminals.

You can spend a lot of money on one of these

tools, but it you hunt carefully, you can find

something like this one, which is only $31 for all

that stuff. Although sometimes you get what

you pay for. The crimp type normally used for open

barrel terminals I offer in my page is the die set

in the center. The others might come in

handy, so they would be a bonus. I don't own

this one. My fancy racheting crimper was

about $80 ten plus years ago from Summit Racing.

This one is cheap and might be worth the cost, or

it might explode. You can never really tell until

it's in your hands.

<<<

For a tool

that's a bit more fancy, look for a ratcheting

crimper that will do open barrel F type terminals.

You can spend a lot of money on one of these

tools, but it you hunt carefully, you can find

something like this one, which is only $31 for all

that stuff. Although sometimes you get what

you pay for. The crimp type normally used for open

barrel terminals I offer in my page is the die set

in the center. The others might come in

handy, so they would be a bonus. I don't own

this one. My fancy racheting crimper was

about $80 ten plus years ago from Summit Racing.

This one is cheap and might be worth the cost, or

it might explode. You can never really tell until

it's in your hands. HERE: https://www.amazon.com/dp/B01CVH8JNO?psc=1 |

<<< This is an aluminum

Chassis Mount Resistor. It

is NOT something I have tested or used in this

project.

The reason this info is here is because It has been

suggested for durability, particularly in corrosive

or wetter environments. Some of you might want to

consider a different style resistor instead of the

Dorman resistor board I used. Most of the

suggestions people have sent have been pointing to

ceramic automotive resistors, such as those used for

ignition, AC and cooling fans older cars. The

problem I encountered is that there are very

few choices for varied resistance values in ceramic, so it may take a

lot of trial and error to get that working

well. <<< This is an aluminum

Chassis Mount Resistor. It

is NOT something I have tested or used in this

project.

The reason this info is here is because It has been

suggested for durability, particularly in corrosive

or wetter environments. Some of you might want to

consider a different style resistor instead of the

Dorman resistor board I used. Most of the

suggestions people have sent have been pointing to

ceramic automotive resistors, such as those used for

ignition, AC and cooling fans older cars. The

problem I encountered is that there are very

few choices for varied resistance values in ceramic, so it may take a

lot of trial and error to get that working

well. So I began looking closer at these Chassis Mount Resistors. The dimensions for the models listed below are 65 x 47 x 26 mm (about 2.5 x 1.9 x 1.25 inches). They run about $10 each and they're rated for WET CONDITIONS. Most ceramic resistors have only a 30-40 watt capacity. The chassis mount types I have listed below all have a 100 watt capacity. You would need three of them to come close to duplicating the three speeds I have achieved with the Dorman resistor board, however I have not tested any of these yet to see what speeds they will actually generate. Since the four ohm values I found in the Dorman resistor board were 0.3, 0.8, 1.4 and 3.1 (I'm not using 3.1 ohms), you can try some that are reasonably close to that, such as 0.22, 1, 1.5 and 3 ohms.

A source I found for these is DigiKey

Electronics: http://www.digikey.com/product-search/en?keywords=resistor.

If

you

incorporate something like this in your build,

please email me. I would like to know how your

project goes. CONTACT ME.

|

| Completed Project Review After TWO years of use, this controller has worked perfectly. Zero glitches or worries. That's nice for a change. |

||||||||||||||||||

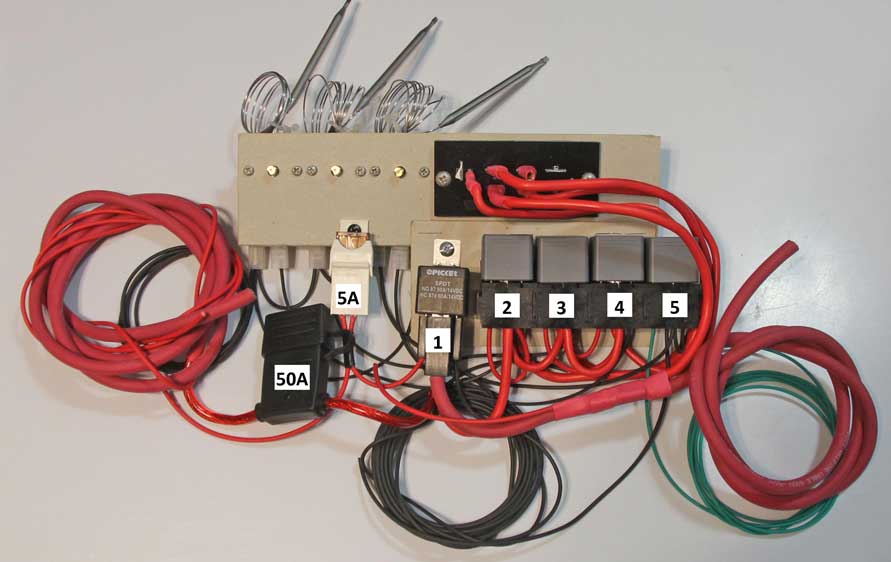

<<< Here's the full

setup installed in my 240. As you can see I opted

for the fancy Hella relay box. Those four

relays in the box are for AC, Low, Medium and High

speed. <<< Here's the full

setup installed in my 240. As you can see I opted

for the fancy Hella relay box. Those four

relays in the box are for AC, Low, Medium and High

speed. |

||||||||||||||||||

|

|

||||||||||||||||||

<<< Another angle.

That relay on the left side of the Hella box is the

80A full power relay. It's triggered by the override

switch on my dash. Hopefully it won't be needed, but

it comforts me to have it just in case. <<< Another angle.

That relay on the left side of the Hella box is the

80A full power relay. It's triggered by the override

switch on my dash. Hopefully it won't be needed, but

it comforts me to have it just in case. This setup has been used in 105 degree plus Texas climate it works exceptionally well. The 77% speed I chose for the AC works very well also. |

||||||||||||||||||

|

|

||||||||||||||||||

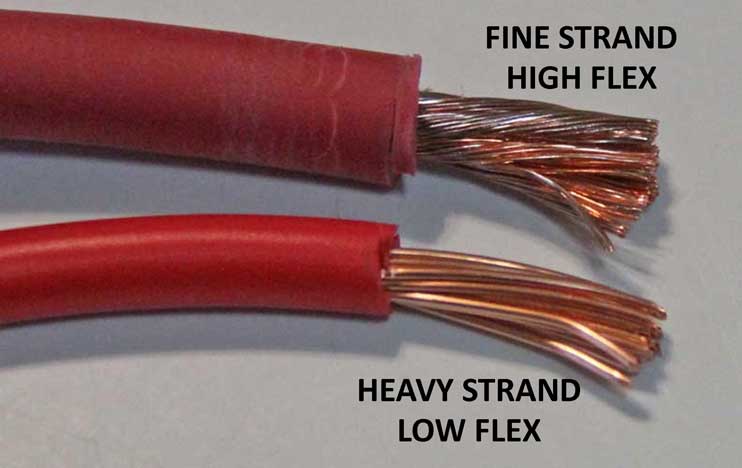

<<< Here's another view of the Dorman resistor board mounted in the lower left corner of the fan shroud. That is 10 gauge high-flex wire. The terminals are .312 inch (headlight terminals), since I found they actually fit better and provide more contact area than the .250 inch terminals that are normally used on there. There are people who thought this resistor board would melt. Two years later and all is working perfectly. So there, stupid doubters. |

||||||||||||||||||

|

|

||||||||||||||||||

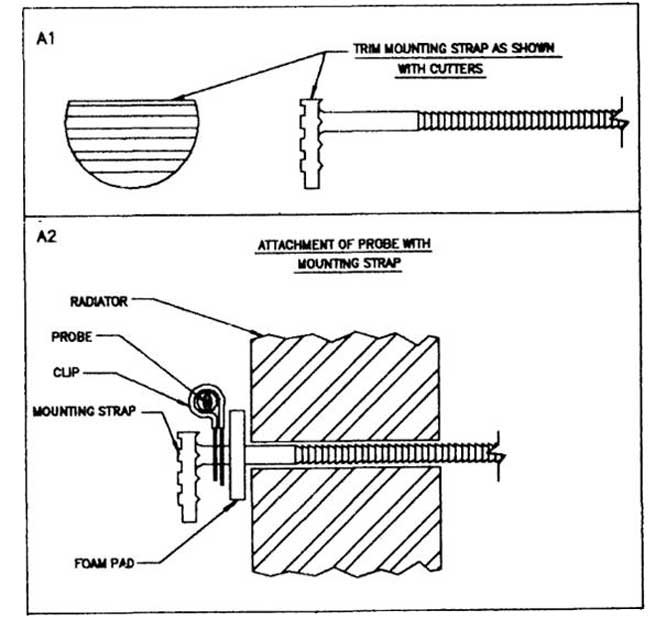

BAD

RECOMMENDATIONS BAD

RECOMMENDATIONS<<< This is worth mentioning if you decide to used a Hayden 3653 temp sensor. It concerns mounting the radiator fin probes in or on the radiator. This image is from their instructions. They supply the shown probe mounting parts and tell you to mount the probe in a supplied metal/rubber mounting strap that is then isolated from the radiator by a foam pad. THIS IS A REALLY BAD IDEA. What this does is delay radiator temps from quickly transmitting to the probe. The delay with mounting it this way is substantial. It has slightly less of an effect when hot air from the radiator is blowing through and past the probe, but there will be signiificant delay when warming up the engine (if the fan is not blowing) or if the car is not moving and air is not flowing yet. The delay will be such that the radiator will heat up PAST the setting you want for the fan to come on, so then your fan comes on late. Then it will DELAY the fan from shutting down as the radiator temps drop off, causing wide swings of the fan on/off cycle. You'll curse Hayden because you wont be able to accurately dial in your settings. It's just bad. Don't follow those instructions. |

||||||||||||||||||

|

|

||||||||||||||||||

<<< DO

THIS INSTEAD: The probes that come with these

units are a bit fat and would not slip into my

radiator fins without a lot of force. This may

be why Hayden wrote those instructions that

way. I didn't want to risk damage to my

expensive aluminum radiator by bending things and

forcing the probes in, so I mounted the probes

tightly against the radiator fins as shown in this

photo using thin zip-ties. While it might be hard to

tell in this photo, the

full length of each probe is very snug against the

radiator fins and they have good, solid contact. Sensor activation

with this method is quick and accurate. Faith

in Hayden has been restored. <<< DO

THIS INSTEAD: The probes that come with these

units are a bit fat and would not slip into my

radiator fins without a lot of force. This may

be why Hayden wrote those instructions that

way. I didn't want to risk damage to my

expensive aluminum radiator by bending things and

forcing the probes in, so I mounted the probes

tightly against the radiator fins as shown in this

photo using thin zip-ties. While it might be hard to

tell in this photo, the

full length of each probe is very snug against the

radiator fins and they have good, solid contact. Sensor activation

with this method is quick and accurate. Faith

in Hayden has been restored. |

||||||||||||||||||

|

|

||||||||||||||||||

<<< Here's the override switch I placed on my dash. The small LED bulb below the switch illuminates green when the fan is on. |

||||||||||||||||||

|

|

||||||||||||||||||

<<< The LED turned out to be too bright with full 12 volts, so I added a 220k ohm resistor to the power wire. Now it seems just right with a low green glow. |

||||||||||||||||||

|

||||||||||||||||||

|

PARTS INVENTORY

Update 2017: The dorman version of the Lincoln Mark VIII fan with shroud is available on Amazon here cheap: https://www.amazon.com/gp/product/B001SGHK1W/ref=pe_850140_225176060

Relay - Picker High Current 80A

relay (SPDT). Qty

1.

Available here:

https://www.prancingmoose.com/volvorelays.html#highcurrentrelay Relay - Tyco gray “101” 40A

relay (SPDT). Qty:

4.

Available

here: https://www.prancingmoose.com/volvorelays.html#1259926-101gray Relay plug socket,

interlocking, 5-pole. Qty:

4.

Available here:

https://www.prancingmoose.com/volvorelays.html#relayplug Optional

- Hella H84988001 Sealed Box for four relays. Qty: 1 Relay high-current plug socket,

5-pole. Qty:

1.

Available here:

https://www.prancingmoose.com/volvorelays.html#highcurrentplug

Fuse holder (mini fuse) with 5A

fuse (18 gauge wire). Qty: 1 Fuse holder (maxi fuse) with

50A fuse (8 gauge wire). Qty: 1. Hayden 3653 adjustable temp

sensor. Qty: 3. Resistor pack -

Dorman 973-018 4-speed fan resistor. Qty: 1. Diode - PN

IN5408.

Qty:

1.

Wire - 8 gauge (high flex

welding cable recommended). Qty: about 8 feet red. Wire - 10 gauge (high flex

marine grade recommended). Qty: about 2 feet red. Wire - 16-18 gauge auto primary

wire. Red and black. Qty: about 8 feet red and

black. Heat-Shrink Tubing - Varies

sizes (maybe 3/8 to 1/2 inch) in black or red and

black. Toggle Switch -

On/Off for high speed relay override wire.

Dash mounted. Qty: 1. Crimp terminal - .375" (9.5 mm)

female, 6-10 gauge (for high-current relay). Qty:

3.

Available here:

https://www.prancingmoose.com/blackvinyl.html#.375inchterminals Crimp terminal - .312" (7.9 mm)

female straight, 10 gauge (for Dorman resistor).

Qty: 4. Available here:

https://www.prancingmoose.com/blackvinyl.html#headlightplugs Terminal Overcrimp (optional) -

Large (for Dorman resistor terminals using 10 gauge

wire). Qty: 4. Available

here: https://www.prancingmoose.com/blackvinyl.html#overcrimps Crimp terminal - .250” (6.3 mm)

female, 10-12 gauge (for relays). Qty:

7.

Available

here: https://www.prancingmoose.com/blackvinyl.html#.250inchplugs Crimp terminal - .250” (6.3 mm)

female, 14-18 gauge (for relays). Qty:

12.

Available

here: https://www.prancingmoose.com/blackvinyl.html#.250inchplugs |

| davebarton.com |

prancingmoose.com |

240turbo.com |

Special Emblems |

| Prancing

Moose Stickers |

Volvo

Stickers |

Body/Chassis/Engine

Labels |

240 MODS and FIXES Page |

| Other Car Brand

Stickers |

Steering

Wheel Labels |

Center Cap Labels/Overlays |

Cool Volvo

Products |

| Grill Labels/Overlays |

Volvo Wire

Harnesses |

Conversion Harnesses |

Harness

Parts/Connectors |

| Volvo Relays |

Coil Repair

Harnesses |

240 Window

Scrapers |

740/940

Window Scrapers |

| Adjustable Voltage

Regulators |

Horn Buttons |

240 Odometer

Repair |

740 Odometer

Repair |

| Volvo Gauge

Faces |

740

Turbo/Boost Faces |

240 Black Door Vinyl |

850 Odometer

Repair |

| ALTERNATOR Page |

240 Power Mirrors - Switches |

240 Oil Cooler Page |

240 Fuse Panel Page |

| Group A

Racing 242 Turbo Page |

240 Hydraulic Clutch | Fuel Pump RELAY Page |

240 Headlight RELAY Page |

| Used Parts & Extra Stuff for sale |

CRIMPING Page |

240 Ignition Page |

240 Headlight Page |

| 240 Gauge Electrical Diagrams | 240 REAR END Page | Yoshifab Catch Can Install | 240 TAILLIGHT Page |

| Side Marker

Lights Page |

Gentex Mirror Upgrade | Yoshifab Drain Tube Install | Modified 240 Favorites |

| SoCal Salvage Yards | Unleaded Racing Fuel | B26FT Stroker | Dave's 245 Spec Page |

| 240 SUSPENSION Page | 240 Lowering Page |

240 Windshield Page |

240 WIPER Page |

| 240 BRAKES Page |

240 Dash Top Gauge Pod | Cadillac 4-Note Horn Install | 240 DYNAMAT Installation |

| 4 Speed Fan

Controller |

Electric Cooling Fan

Page |

BRUSHLESS Cooling Fan Page |

Tropical Fan

Clutches |

| 240 AC Page | "KOMFORT BLINKER" Upgrade | T5 Trans Conversion Page | 240 Engine Mount Page |

| 240 VIN Page | Stepper Idle Valve Page |

Vacuum Diagrams | 240 HOOD Page |

| 240 Exhaust Page | 242 Power Vent Window Project |

EFI Volvo Pin Function Diagrams |

Favorite Links |

| R-Sport

Apparel |

Prancing

Moose Apparel |

Volvo Meet Photo Albums | Texas Volvo Meets and Events |

| Ordering Instructions | Policies | PAYMENTS Page |

Mojave Road Trail Map Page |

| Returns | Shipping | Shopping Cart Troubleshooting | Contact Us |

|

|