2 4 0 T U R B O .

C O M

|

2 4 0 T U R B O .

C O M

|

| YOUR COMMENTS ARE WELCOME CONTACT ME |

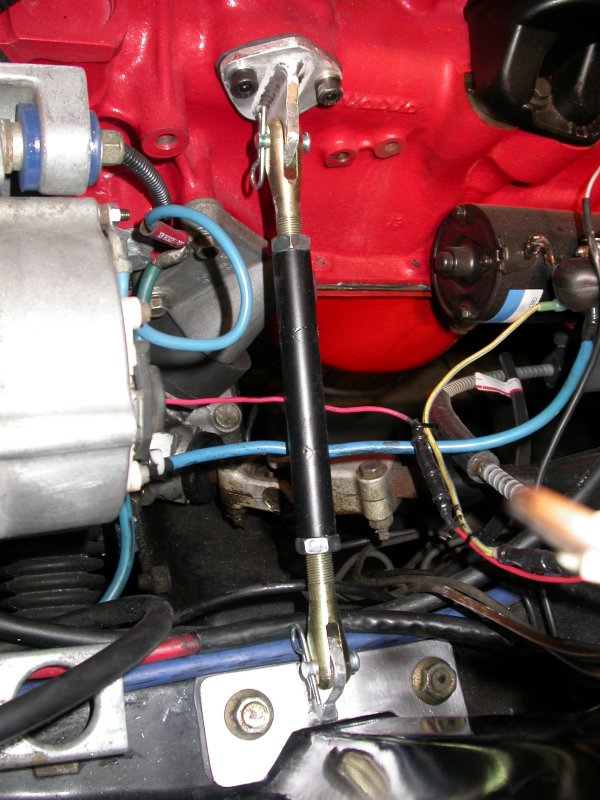

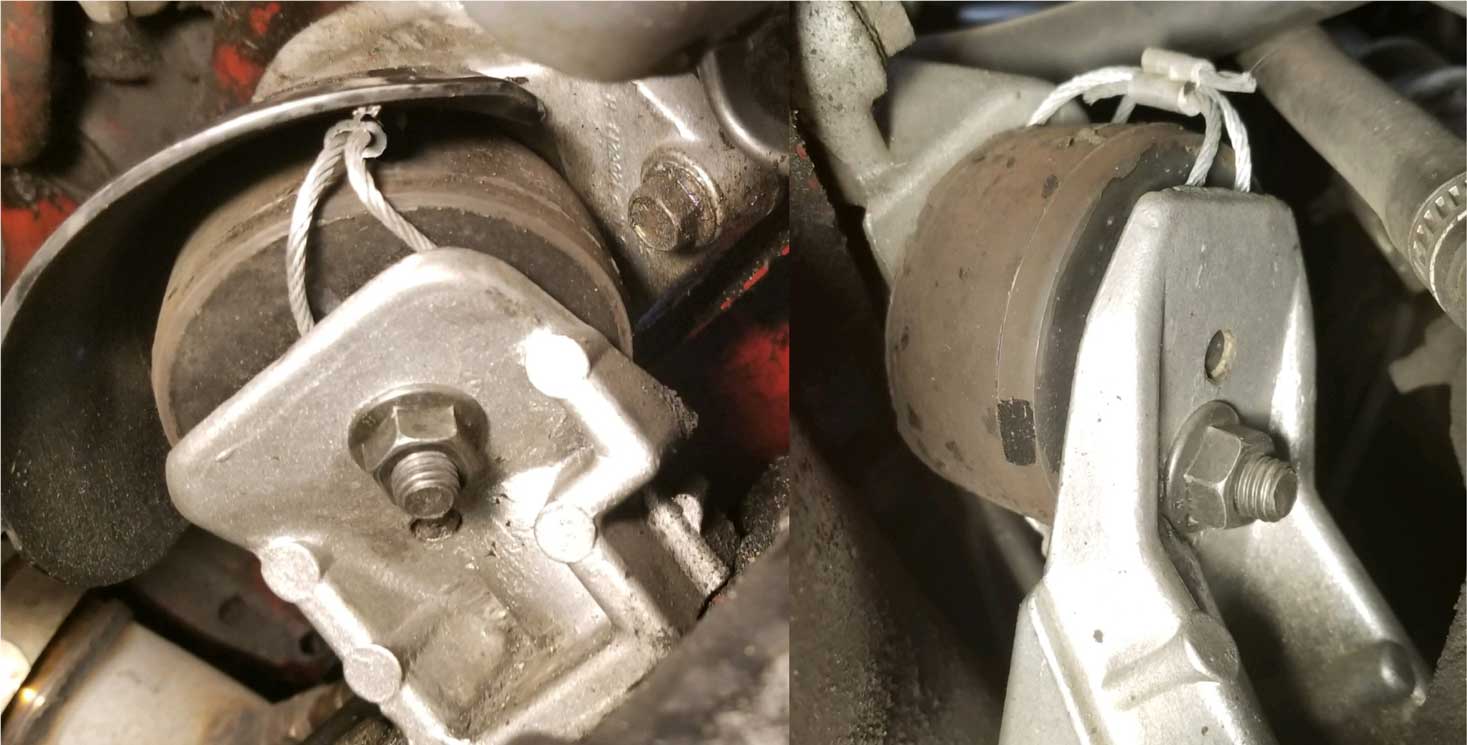

So in this page I'll go over some ideas about better options for high-performance mounts. 240 Engine mounts were designed by Volvo to be pretty simple, but they were designed with a purpose beyond just anchoring the engine. They were designed to be part of a three piece cradle system. The transmission mount is the third piece. The engine mounts are slanted inward and back, while the transmission mount is slanted forward. This system acts as a cradle to hold the engine and transmission as a unit in place, while providing a reasonable amount of rubber damping for driver comfort.    The factory rubber mounts offered from Volvo came in the normal softer rubber type or in a harder rubber, which came in diesel engine cars. Normal 240 mounts: LEFT PN 274110. RIGHT PN 274111. D24 DIESEL 240 (heavier duty) mounts: LEFT PN 1229805. RIGHT PN 1272346. I should add that it's my intent to focus this information on STREET cars, since a race car really doesn't need much vibration damping or driver comfort. We know the original mounts can tend separate when abused or in a high-performance environment, some people have used creative ideas to keep their engines in place. Some are shown here.         The most common idea has been to add a limiting strap (maybe a cloth cargo strap) or a rigid extra mount, sometimes called a THIRD MOUNT, such as those pictured ABOVE. Some of these may work just fine to help share the load going to factory engine mounts. Some of these may not provide enough (or any) actual damping to eliminate undesirable engine vibration. It seems a lot of people have differing opinions about these. I've been tempted, but I've never used a third mount in all these years. First photo below: https://www.anderssonsteelspeed.240-b23-b230. Next photo: Black Yoshifab mounts: https://yoshifab.com/240mounts. Next: Green poly mounts: https://www.classicswede.org.uk/polymounts.    There are limited options if you want to buy ready made high-performance engine mounts. In my opinion none of the above mounts are suitable for a street car if you want them to reasonably isolate engine vibration from the passenger cabin. Now I'll share what I did in my car in 2019. Photos BELOW are not my car, but this pretty much shows what can happen to a factory 240 engine mount when abused or neglected.   You can consider the below thing I did to be experimental if you prefer, but keep in mind this has worked flawlessly for 7 years. This cable is 3/16 inch galvanized steel cable with some standard cable crimp sleeves.   It's not complicated. I just cut and crimped some cables for my OEM mounts. My hope was that they would restrict a catastrophic separation or failure. In the SEVEN years since, after more than 25k miles, there has been NO failure. LEFT SIDE MOUNT BELOW.   RIGHT SIDE BELOW.  Follow-up photo of both sides after SEVEN years and many miles. Still perfect.  TRANSMISSION MOUNT If you're curious about the trans mount I'm using (for my T5 transmission), You can see THIS PAGE HERE

|

|

|