|

Installing a Later 1991-93 Windshield

into an early Volvo 240 (or 140).

This is a VERY common 240 mod with

a fair amount of info already out there. But

since I still get regular questions about

this, I decided to post this page.

The 240 was built from 1974 (1975 model year)

to 1993 and the body design changed very

little over the 18 year production run.

The windshield structure had no changes

whatsoever between 1974 and 1993. Even in an

earlier 140, the windshield structure is

identical to the 240. You may

have noticed that all 1991-93 240s came with a

different type of windshield trim than those

found on earlier models. It's all black

and made of rubber. No metal trim is used like

on earlier 240s.

1975-90 240 (and 140) windshield with metal

trim: This early type of

windshield was glued in place using a soft,

messy butyl rubber. Plastic trim clips were

inserted into the soft rubber to hold the

metal trim in place. This trim tended to

stick up from the windshield too far and in

many cases it created lots of wind

noise. Thanks go to Ben Buja for

supplying this photo.

|

| 1991-93 240 windshield with integral rubber

trim: As you can see below,

this later type black rubber trim is nearly

flush with the body. The trim is cleaner looking

and it can reduce some of the wind noise when compared to older metal trim.

Above image shows original Volvo later trim.

When you purchase a newer 1991+

240 windshield, it will always come with the black

rubber trim already attached around the

edge, but if you buy a non-original

windshield, the trim will appear different compared to an original Volvo

later windshield. Rubber trim may also be available

separately if needed.

For a later windshield like this one above, the

installer may use a newer style URETHANE rubber

when gluing it in, instead of the soft, gooey,

messy BUTYL rubber used in original older installations.

Here I'll detail are some differences between the LATER TRIM on a GENUINE VOLVO windshield and many AFTERMARKET style trims.

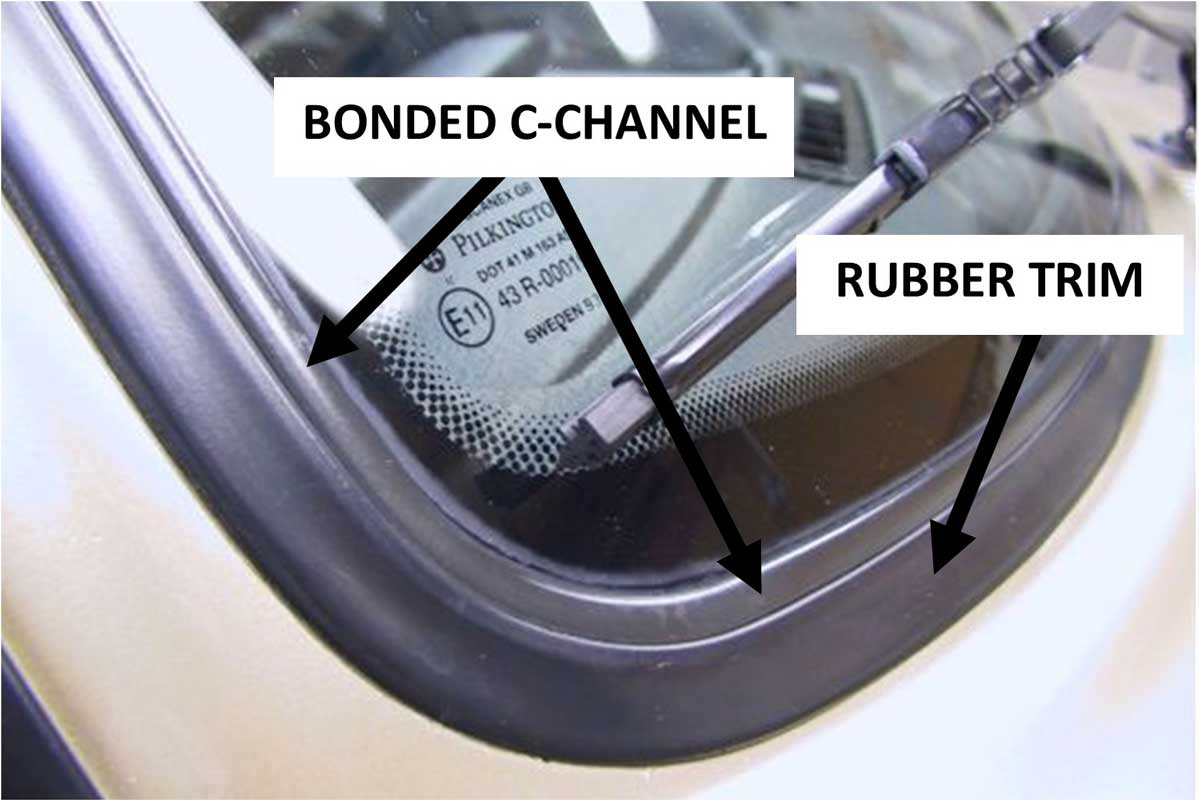

The trim on the GENUINE Volvo windshield

is made in two parts. The glass has a

black C-channel, which is bonded to the outer glass edge. Then the rubber seal or rubber trim is a

separate piece on the original later windshield. The C-channel can be seen

also by itself in this second photo below if you look closely. The outer molding has been cut

away during windshield removal.

It would be possible to use an original

Volvo rubber seal IF you could still source the black C-channel (this channel is NLA). The original

outer rubber seal is still available as Volvo PN 3540053 (like this from iPd), but the C-channel is NOT, so you would need to improvise that part with some other universal C-channel molding if you can.

Using the original Volvo rubber seal without the C-channel would not

likely work out well, since it probably would not be wide enough to cover the edge of the body channel.

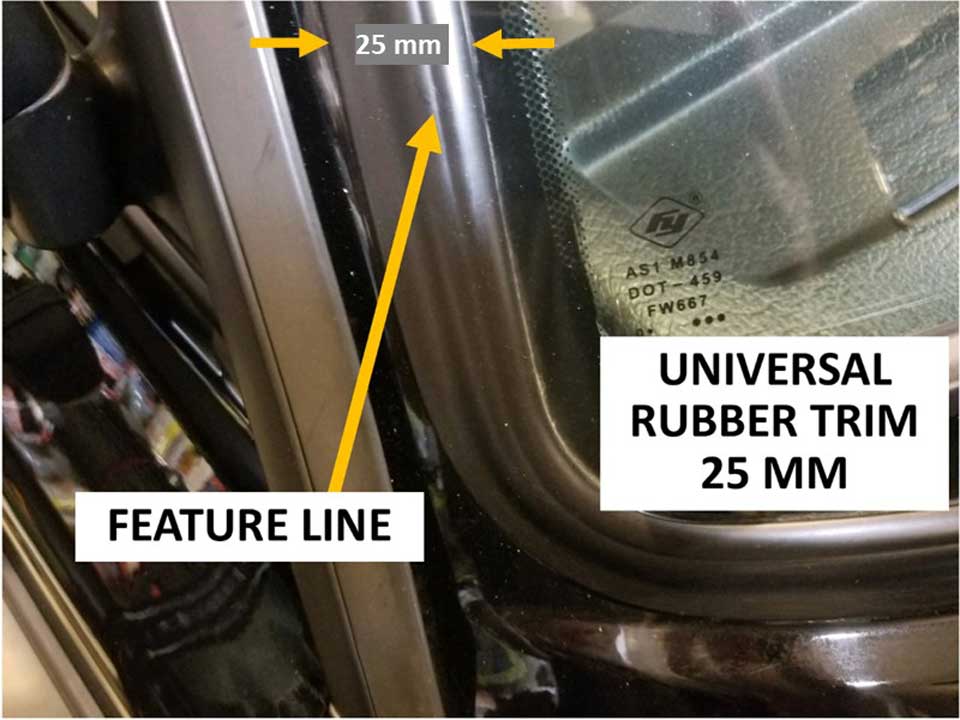

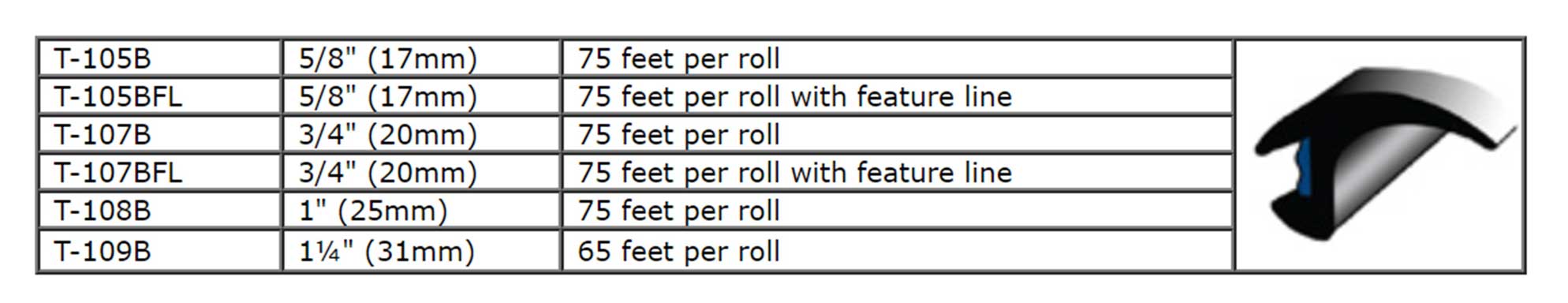

Most

aftermarket later windshields will instead have a ONE-PIECE universal

rubber trim around it. Sometimes this trim comes with a "feature line,"

which appears to mimic the two-piece look of the original trim.

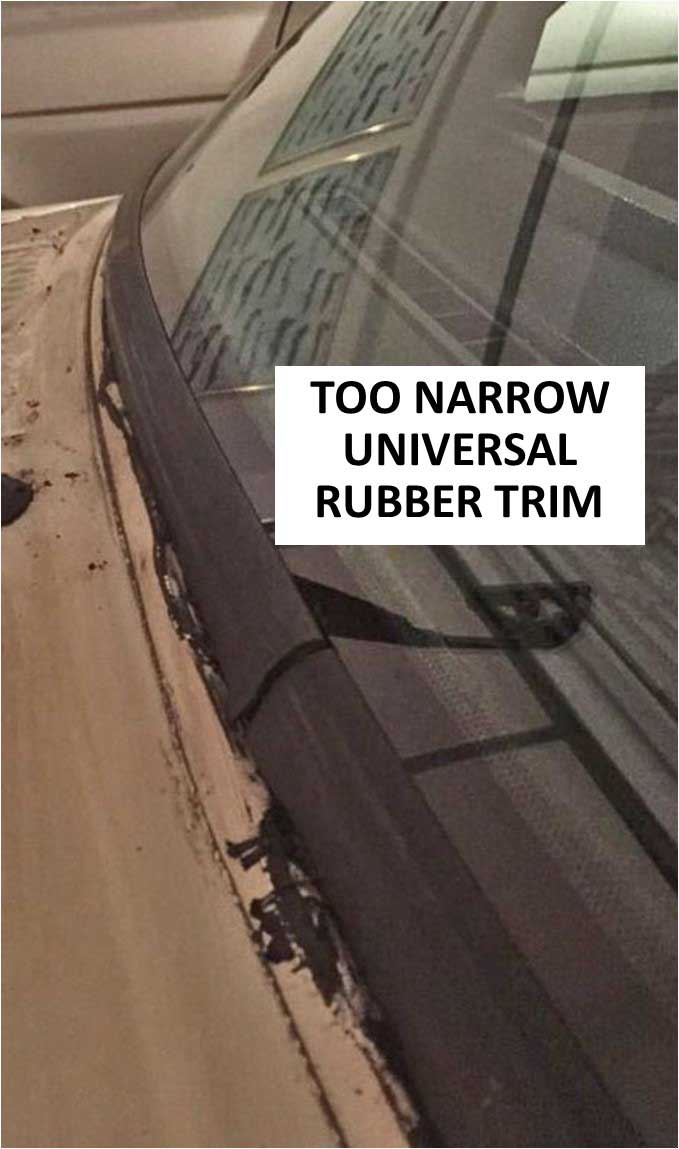

Be aware that some cheap windshields have been found with very narrow 18 mm universal molding.

Often that narrow molding will not cover the surrounding area very well,

especially if there's a paint line or other imperfection that becomes exposed with a narrow seal like that. If the windshield comes with such a narrow seal, you might ask the installer or shop if you can get or substitute WIDER molding. Wider molding is available (CLICK HERE).

Many aftermarket windshields will come with 25 mm wide molding. Most people seem to be happy with 25 mm wide molding, but if that's not wide enough, wider 31 mm is available further below.

SOMETHING A BIT DIFFERENT

This photo below is from the 240 windshield re-sealing page found at fewstreet.com/240-windshield.html.

It details the use of universal trim to reseal a 1989 windshield in a 1989 240.

WIDER TRIM THAN 25 MM?

If you need wider trim, 31 mm universal molding is available. This wider 31 mm molding is used in the below DIY installation.

There is one possible problem with this wider seal that you should know. The

turns around the corners of the windshield can "pucker." This effect

can be seen in the below photos. A talented or experienced

installer may be able to lessen that with some care.

Otherwise, fitting a later windshield to an earlier 240 (or

even a 140) is not a problem at all. It goes right in

with no difference in the installation technique.

SOME INSTALLERS ARE NOT INTERESTED

Be aware that there are installers out there who

aren't aware that the 240 body design never

changed in all the years it was made. They may be skeptical about

installing a later windshield in an early 240. Some will even

refuse to do such an install because they

won't believe you when you insist it fits.

But rest assured, the newer windshield WILL

fit. Many 240 owners have done this over the

years.

If you want to avoid the

argument,

just tell the installer the car is a

'91, '92 or '93.

Here's a comment from T.M. of

White Marsh, Virginia: "I took your advice about using a 1991

windshield in my 1987 240 Volvo. Just like you

suggested, in your article, I told the

installer I

needed a 1991 windshield for my car.

When I brought my car in, the receptionist

goes out and looks at my car's ID tag and sees

it's am '87. She freaked out. She was

all like, "it won't fit", "I won't give you a

warranty," and if I insisted on putting this

windshield in the car I would be responsible

when it all went wrong. I told this

receptionist that it would fit, it would be

easier for the workers to install, it would

look just fine, and that she already told me I

wouldn't have a warranty anyway, because she

said I had rust in the channel. So what is the

difference? She got all huffy when I

told the installers to proceed anyway and to

ignore her. She was in a bigger snit

when she saw that it fit and looked just fine

too. There was NO rust in the channel, but I

didn't really care about her silly warranty

anyway."

"You were totally right, the wind

noise is much less, and the installation was

so much cleaner. I'm glad I took your advice

everything is great; not original, but

actually better. One freaked out receptionist,

two satisfied installers, one happy customer,

and one slightly improved Volvo. A good

day was had by most of us anyway. I

don't think the receptionist is ever going to

forgive me for "lying" to her about the year

and having it all work out just fine. lol."

USING ORIGINAL BUTYL or MORE MODERN URETHANE

Early 240s windshields were installed using black butyl,

which is very sticky and messy and never hardens. The more modern

technique uses URETHANE, which will harden. A professional installer

will most likely use a 2-part urethane,

which hardens even faster. If you install your own windshield, you can

choose either adhesive, but in most cases if you have your windshield

installed by a pro, they'll use urethane.

Here's a

TB discussion:

turbobricks.com/240-windshield.375462/

Or try a search for more:

google.com/windshieldinstallationturbobricks

|

DIY INSTALLATION

In 2018 Michael Yount did his own

installation of a later aftermarket windshield in his

1982 242.

He provided the

following tips below for those thinking of doing

this yourself.

Much of this info was included in a thread here:

turbobricks.com/windshield-support-blocks-240.341873/

|

1.

Removing the old black BUTYL makes a helluva

mess. To keep the car clean, you should completely mask each

A-pillar, and across the top of the car, and the entire

cowl, including covering all the cowl vent

holes. Debris can and will get

EVERYWHERE. Butyl comes off of paint

easy, but if you get it on fabric or carpet

- forget it. You won't get it out.

So cover everything. Use towels or something to cover

the dash, steering wheel, front seats,

floors, etc. And a couple of big blankets

over the entire hood is a great idea, since you'll be repeatedly lifting or setting

the old or new windshield over the hood of the

car.

2. Get two double-suction-cup

handles from Harbor Freight. These work well

for the old and new windshield. One person

can remove the old one. You should have a helper for

installing a new one.

3. Do your best to cut the old BUTYL all

the way around before attempting to remove the

old windshield. If the old windshield is cracked

or you're not trying to salvage it, just

getting the A-pillars and top edge loose will do. Then just pull it away or push from inside.

Old windshields are notably

heavier and thicker than new ones.

4. CLEAN: Your pinch weld should be completely

clean. All you should see is paint. It will take some time.

5. You'll see in the above TB thread, chemicals to remove the old butyl and clean the

pinch weld. Citrus Power Goo Gone or some Xylene (used in a well ventilated area).

6. You can use guitar/safety/piano wire

as a cutter, but know it will try to hang up

on the old plastic clips used for an older

windshield. Those clips were used to hold the older trim on. First remove the old stock trim so

you can see where the old clips are and navigate

around them with the wire OR you can use a screwdriver to pry out the clips.

7. The new later style windshield comes

with rubber trim molding glued around the

edge. The width of that trim is usually

about 25 mm (similar to T108 universal "T" molding). In some cases that trim is

not wide enough to cover a re-paint line

that may existed if your car was repainted when an older windshield was in place. You can buy new

wider trim molding, T109B universal "T" molding, 31 mm

wide. This trim comes in a 65 foot

roll and can be found at Gold Glass: gggcorp.com/Universal_Mouldings. The direct link to the T109B 31 mm molding is: gggcorp.com/Universal_T109B.

8. If you change that rubber trim

molding on your new windshield,

take your time removing the glued on molding

that came on the glass. It may be glued on with BUTYL. You can use duct tape (the sticky side)

to remove the leftover BUTYL from the edge of the

new windshield before gluing the new wider trim

back on. Cleaning can be done PREPSOL cleaning solvent.

9. Before installing new trim, use a square to get an accurate 90 degree cut

on one end so you're starting with a perfect 90 degree cut edge.

Measure the windshield to find the precise center at

the bottom and start the new trim

there. Work your way all the way

around. It helps to have another person to help

managed the trim as you go. You can use a

small wooden roller to firmly press the trim

onto the edge of the windshield so the BUTYL

inside the trim U-channel sticks to the

windshield well. When you get all the way around and back around to

the bottom center, make a quick cut so you have about

1 inch extra. Then CAREFULLY measure and

accurately make a good square cut to match the other side of the

trim. Cut it about 1/16 inch LONGER than needed and

then squeeze that little extra trim back in along

the bottom edge. YOU ONLY GET ONE CHANCE

ON THAT SECOND CUT -- IF YOU CUT IT TOO SHORT,

DO NOT TRY TO STRETCH IT. If you goof and have a gap, you'll be

better off leaving the gap and trying to

fill it with black silicone or

something.

10. There were some foam pads that came stuck

to the windshield to protect it during

shipping. You can use those for some windshield

SPACER BLOCKS during installation. One on each side of each

A-pillar and two along the bottom to hold it up. You can use 3M extreme duty double

sided foam tape to adhere the spacer blocks into the

channel. The BUTYL seal stays soft, so you must use spacer blocks at the bottom to keep the

windshield from slowly sliding or moving DOWNWARD over

time. The spacer blocks on the sides will keep

it centered. NOTE: The foam spacer blocks I used were

MUCH better than the stock Volvo spacer blocks or the

rubber ones that came with the BUTYL seal kit.

11. TEST FIT

the new windshield after the new seal is

attached but BEFORE you prime the pinch weld or the windshield. Test fit more than one time. The

more times you test fit it, the easier it will be

to accurately stick the windshield correctly on the last placemant.

12. BUTYL PRIMER is on the pinch weld and on the

windshield edge. 3M 08681 Primer will work.

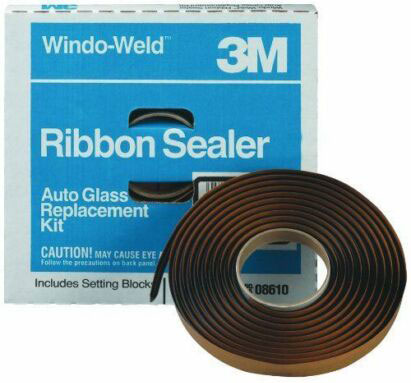

13. Ebay or Amazon BUTYL Ribbon Seal

Kit. (3M

08612 Window-Weld, 3/8 inch wide, 15 feet long).

As

you lay it along the pinch weld, you have to

remove the paper tape to turn the

sharp corners. Then put the tape back on and use the roller to GENTLY apply a bit of

downward pressure before placing the

windshield on. 13. Ebay or Amazon BUTYL Ribbon Seal

Kit. (3M

08612 Window-Weld, 3/8 inch wide, 15 feet long).

As

you lay it along the pinch weld, you have to

remove the paper tape to turn the

sharp corners. Then put the tape back on and use the roller to GENTLY apply a bit of

downward pressure before placing the

windshield on.

14. Once all is primed and all the BUTYL seal is in place

on the pinch weld, then you can finally place and stick the

windshield.

But FIRST, fold

the rubber trim at the corners UP and AWAY from the

body, BEFORE sticking the windshield. As soon as you stick the windshield, check to be sure it's being

held in place (not sliding downward) by the bottom spacer blocks and it is

centered between the side blocks.

Once in place and you're happy with the position, then fold the trim corners down over

the body. Work your way around the trim,

applying pressure all the way around the

perimeter of the windshield several times to

be sure the windshield is pressed cleanly

against the BUTYL and the BUTYL is pressed

cleanly against the pinch weld. This will ensure a good waterproof seal.

15. Cross your fingers and then check for leaks after it's been there for a few days.

|

BACK GLASS

|

<<<

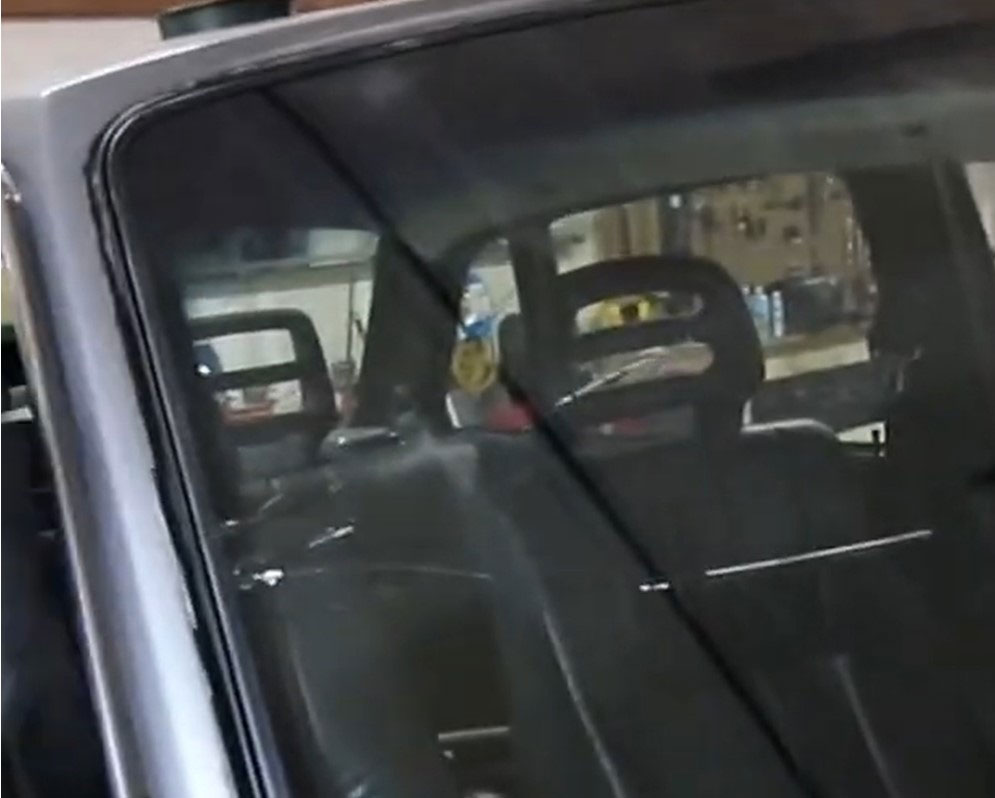

Side note regarding 140 series back

glass: This photo was submitted

by Johnny J. of Sparks, Nevada. His 1973 142

needed a new rear windshield, which was

obsolete. So he took a chance on a rear

glass from a 1990 244. The glass fits

perfectly and wire connectors even line up

perfectly for the defrost element. And the newer

rubber seal from the 1990 glass went right in.

So this shows that any 240 back glass will

perfectly replace the back glass in a 140 series

in case you need to know. <<<

Side note regarding 140 series back

glass: This photo was submitted

by Johnny J. of Sparks, Nevada. His 1973 142

needed a new rear windshield, which was

obsolete. So he took a chance on a rear

glass from a 1990 244. The glass fits

perfectly and wire connectors even line up

perfectly for the defrost element. And the newer

rubber seal from the 1990 glass went right in.

So this shows that any 240 back glass will

perfectly replace the back glass in a 140 series

in case you need to know.

|

|