| VOLVO 240 EXHAUST PAGE |

|

Updated: May 22, 2024 CONTACT

|

D O

M A I N S   |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 240 Exhaust Basics |

240 Custom Exhaust |

Larger Exhaust |

| Mandrel vs Crushed Bends? |

Eliminating Drone |

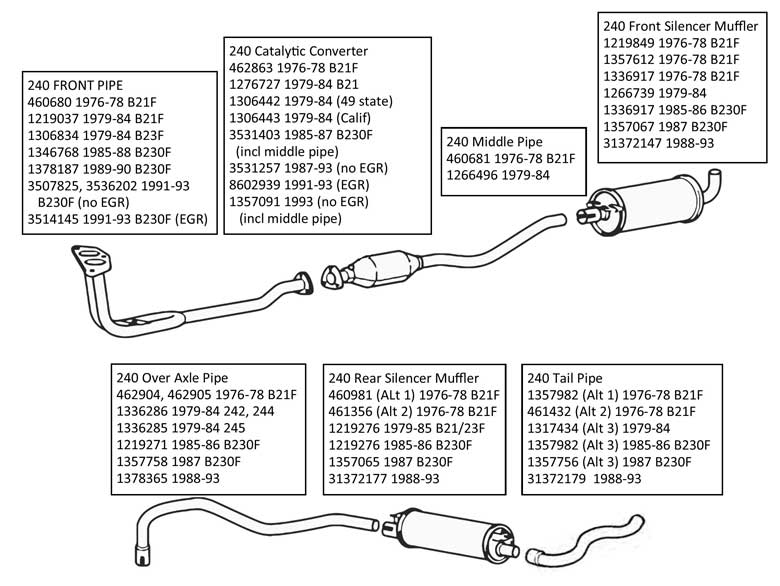

| 240 EXHAUST BASICS |

| 240 CUSTOM EXHAUSTS |

| For those of you interested in building a custom exhaust for your car, here are some topics you may be interested in. LARGER EXHAUST I have been a hot-rodder for many years and I'll be the fist one to tell you a bigger exhaust will usually help with engine power and fuel economy. There are a number of articles and videos available which will demonstrate the difference. My personal belief is that a larger exhaust is worth the price for a TURBO or NON-TURBO car, however a non-turbo will pretty much always see LESS return for the money spent. Plus in most cases a larger exhaust is going to be louder inside and outside the car, depending of course on the muffler combination you select. In the early 1990s my first 240 was a 1983 244 DL. I improved the exhaust on that car by installing a larger 240 Turbo 2.3 inch exhaust "back-half," which was inserted beginning at the back of the original catalytic converter (a cat-back exhaust). I installed a used factory 240 turbo exhaust from a salvage yard. It did noticeably improve performance. These days you can find just such a "cat-back" system for a non-turbo car from places like iPd.  Here's a video of this type of exhaust being installed. https://www.youtube.com/watch?v=tHzaRl3QSkw EVEN BIGGER EXHAUST Years ago I had the below 3 inch exhaust built for my 240 Turbo. The down-pipe was custom made using mandrel bent tubing. The rest of the exhaust was made by a local exhaust shop using standard 3 inch aluminized tubing, using an economical crush-bending method. A 3 inch catalytic converter was used and one large 3 inch muffler was put in back. If you're curious about a performance comparison between mandrel bent and crush-bent: CLICK HERE.   The 3 inch catalytic converter above was placed in a non-original location for a 240 turbo, although that location is the normal location for a non-turbo car. In some places where more strict emission rules apply, this location may not be acceptable, although this worked fine for all the years I lived in California and had to smog test the car every two years. Reportedly a larger exhaust will help a turbo spool up faster. That's a hard thing to quantify, but what about the horsepower gain with a bigger pipe? Here's an episode of Engine Masters where they dyno tested a 2.5 versus 3 inch exhaust. Definitely good info to know.

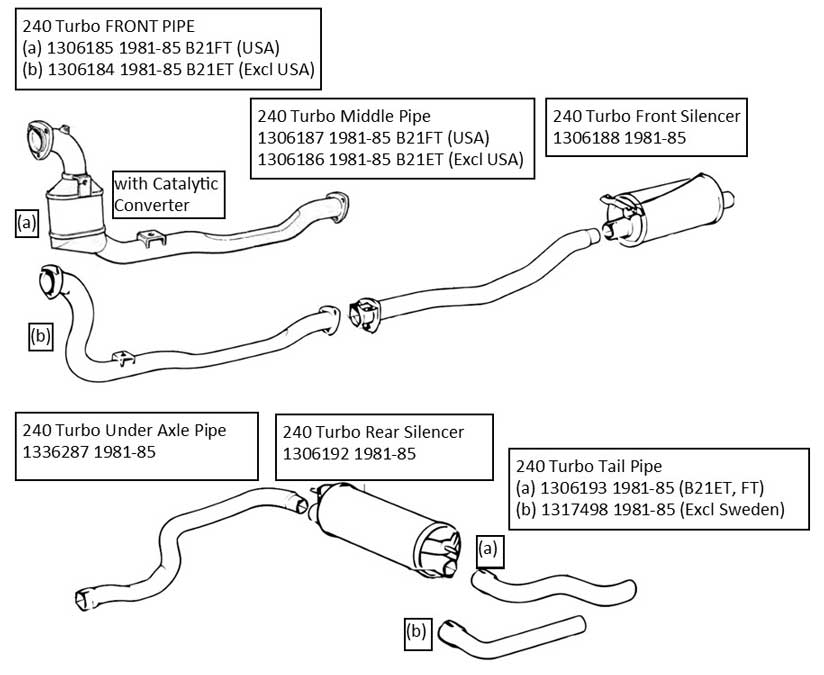

BUILDING A CUSTOM TURBO EXHAUST The first thing you'll need when you decide on a custom TURBO exhaust will be the downpipe. The most common or original turbo found in a 240 Turbo will have a 3-bolt "cone" shaped flange on the exhaust side as shown below, which is made for a 2.5 inch flange.  If you're going for a larger 3 inch pipe, there are transition flanges available to create a 3 inch downpipe for the above turbo. Usually searching for a "Saab turbo downpipe flange" will find something useful. Sometimes these can only be found in Europe. The first photo below is a 2.5 to 3 inch flange, which was offered by GenuineSaab.com off and on in the USA (2023 link here: https://genuinesaab.com/catalog/product_info.php?products_id=621). This is one I have used before, but it has been discontinued off and on, so ask them if the link vanishes again. The second photo below is a 2.5 to 3 inch flange that used to be offered on eBay by Zaustworx in the UK. Also a similar one is offered by KSR in Norway. Most performance parts places like this in Europe speak pretty good English and will usually be happy to help with questions.   It's possible to find ready made 3 inch down-pipes also, but often the sources will be outside the USA. The first image below is from Martelius Exaust Systems in Finland.   It's also a good practice to use a FLEX UNION somewhere near the engine to help with vibration, such as the second photo above. Reducing vibration in the pipes will reduce the chances of cracked welds later. It will reduce stress on the pipes as they expand with heat and then contract as they cool. MANDREL BENT versus CRUSH-BENT PIPE Nearly everyone will tell you for the BEST performance you MUST build a mandrel bent exhaust. Anyone with eyes will agree that smooth consistent bends without any bottlenecks will flow better, but you might be surprised about the real world difference. I saw an episode of Engine Masters on Motortrend TV that offered some of the best evidence toward an answer. In Season 6, Episode 83: Mandrel- v. Crunch-Bent Exhaust, (subscription may needed to watch) a 530 HP naturally aspirated V8 was dyno tested with both exhaust types. The difference between MANDREL BENT 2.5 inch and CRUSH-BENT 2.5 inch exhaust was less than 10 hp at a 530 hp level. So you may consider this if the cost increase for a mandrel bent system is significantly more money. |

| EXHAUST DRONE |

Looking at the photo of this exhaust above, there is no intermediate muffler between the catalytic converter and rear muffler. I was getting an annoying drone a during a narrow RPM window at highway speeds. A few years after this photo was taken I added a small 12 inch glass-pack style resonator after the cat in an effort to reduce drone. It helped a lot. Now there may be a more modern approach. Have a look at the below videos. Eliminating Exhaust Drone with a J-Pipe (Helmholtz) Resonator https://www.youtube.com/watch?v=ds72D4rr4hg https://www.youtube.com/watch?v=cwWK-xz7jho https://www.youtube.com/watch?v=l9CrmkIxDQU If you have any comments or any experiences with the above J-Pipe methods, please email: CONTACT |