2 4 0 T U R B O . C O M

D A V E ' S V O L V O P A G E

| Volvo 240 Hydraulic

Clutch and Stuff |

|

UPDATED: September 20, 2025 CONTACT

|

D

O M A I N S   |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Nothing here is for sale (at least from me).

Let me BACK UP a bit before I get to

the hydraulic clutch info.  This is the "heavier" or "stiffer" modified 8.5 inch clutch I put into my 245 way back in 2004 when I first installed the T5 transmission into behind 2.6 liter stroker. This clutch was "custom" made from Clutchnet in SoCal. It failed badly because it had major slipping in freeway gears under boost. So Clutchnet said "Oops, sorry." Then they made a new custom clutch that was a lot stiffer (below). |

|

|

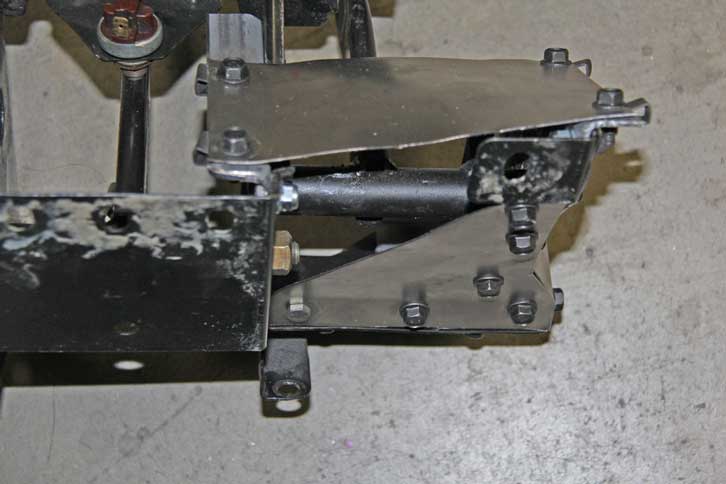

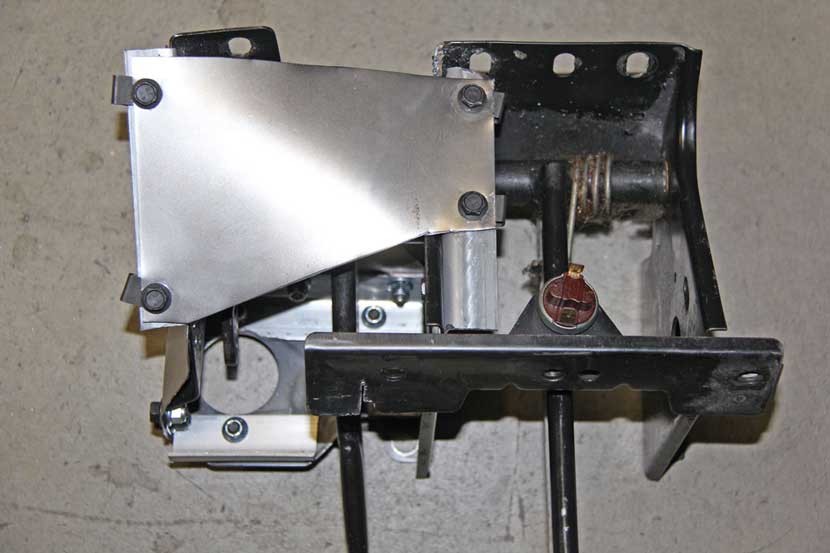

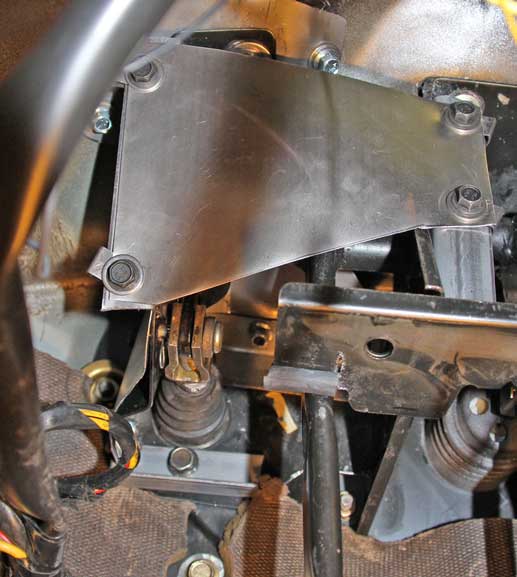

| This new much heavier pressure

plate below was assembled using two standard spring

sets stacked together. A very simple idea that worked very well. The result was a clutch with 3000 lbs of clamping force. It was so successful that later Clutchnet began offering it to the public. The friction disc I used was nothing special. Simple stock organic type.  The reason I mention all this is because it will help you understand why this heavy clutch had a tendency to stretch and eventually snap clutch cables. And long before a cable would snap, it would require adjustments often because of all that stretching. Not good stuff in the long run. |

|

|

|

I know someone

who had the same problem. He went to the trouble of modifying his

240 clutch pedal to accept TWO clutch

cables.

So back a number of years ago when I later installed the T5 trans in my 242, I went with the same clutch setup. I know there are better clutch setups available nowadays. Lots more cools stuff has become available over the years because of the increasing popularity of these cars. I'll get around to trying a better one someday. For now, this is what I have. So after a few snapped cables, I knew I finally needed to upgrade to hydraulic. THAT BEGINS BELOW |

|

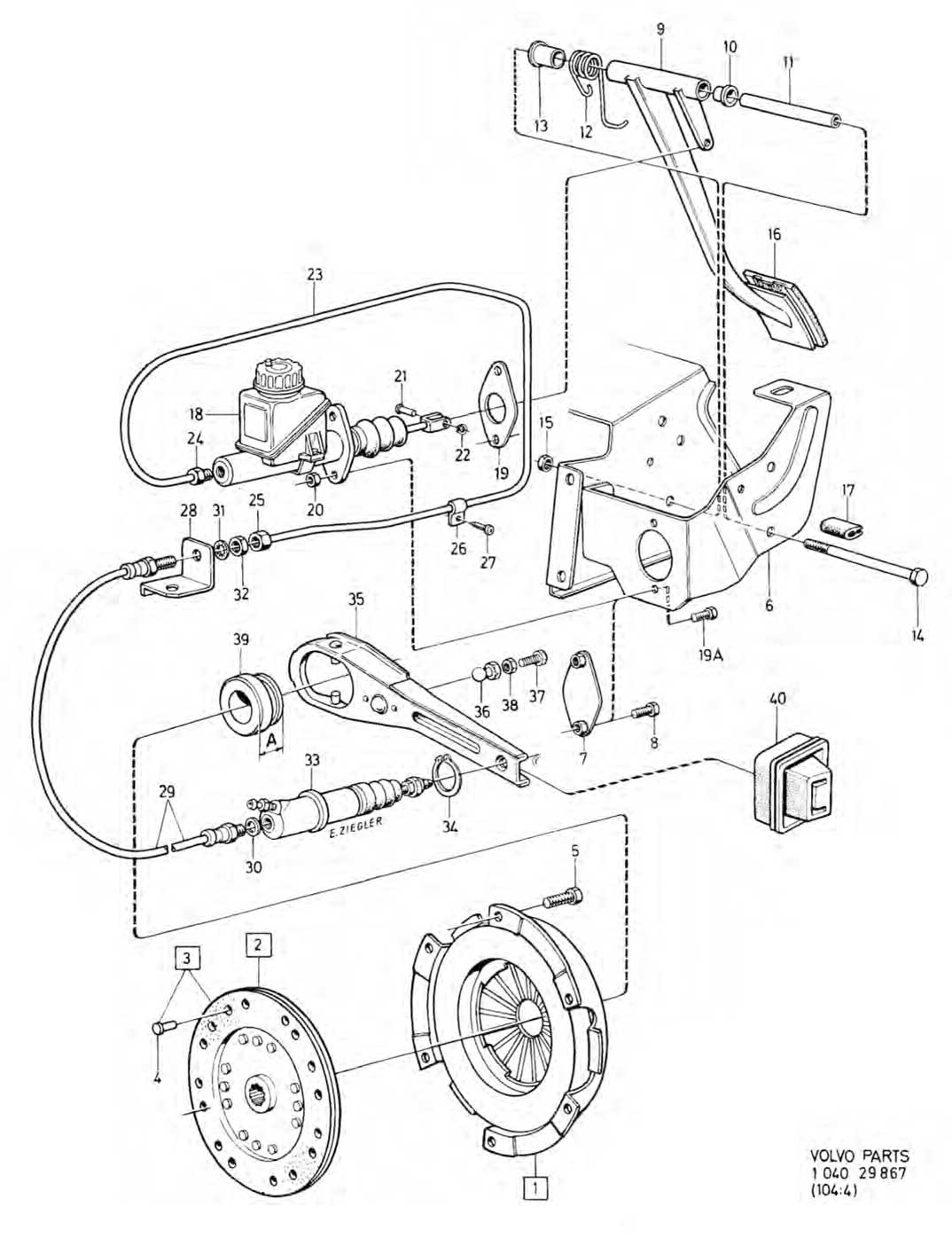

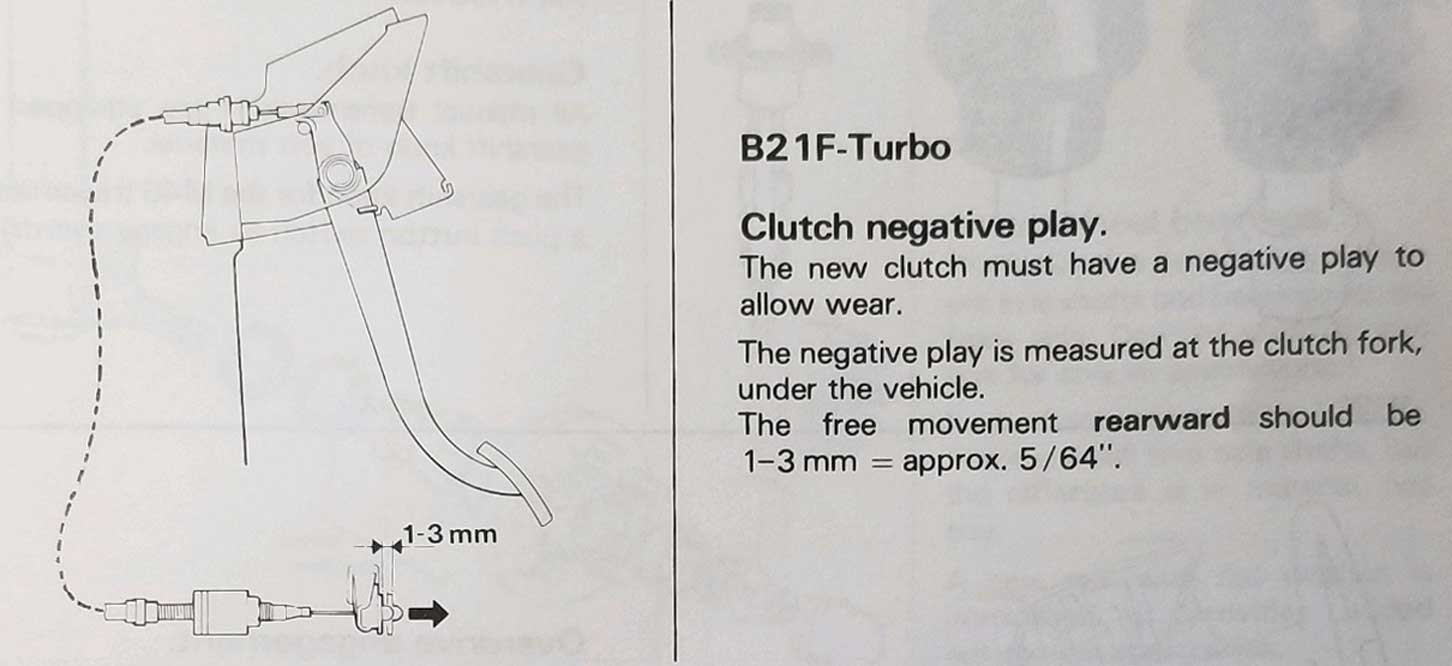

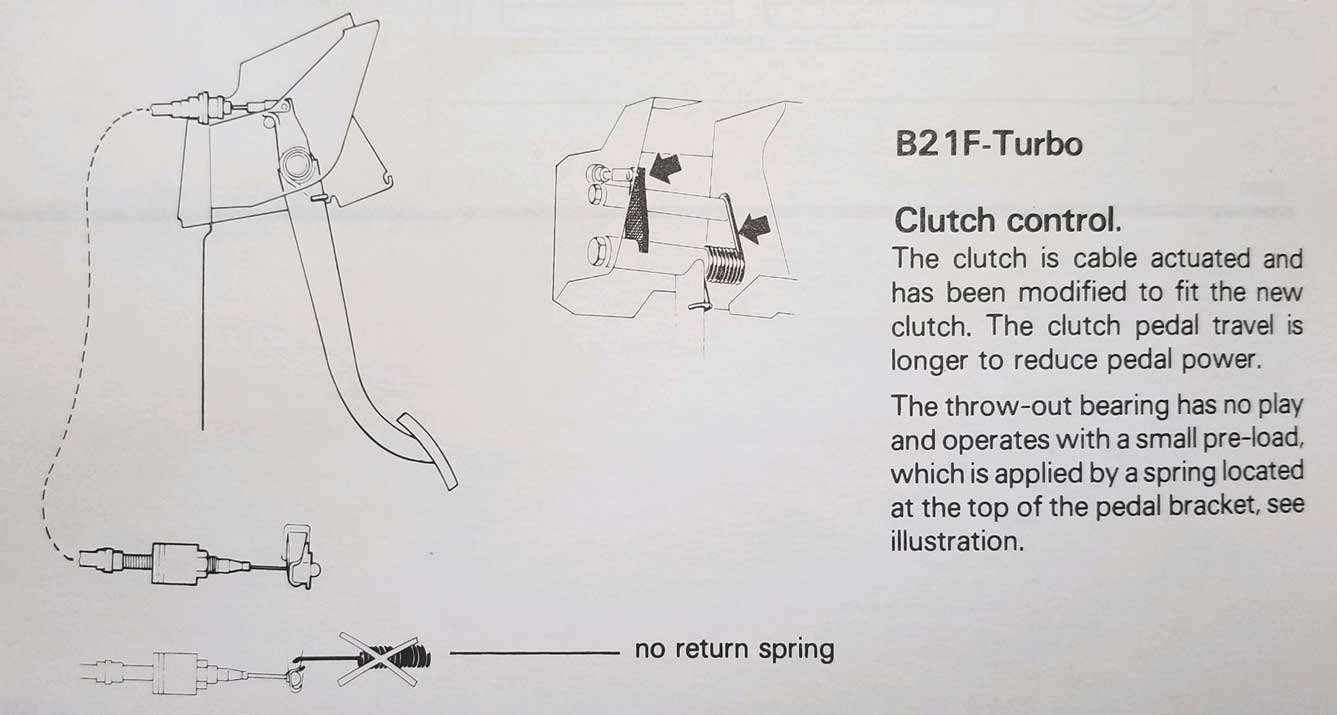

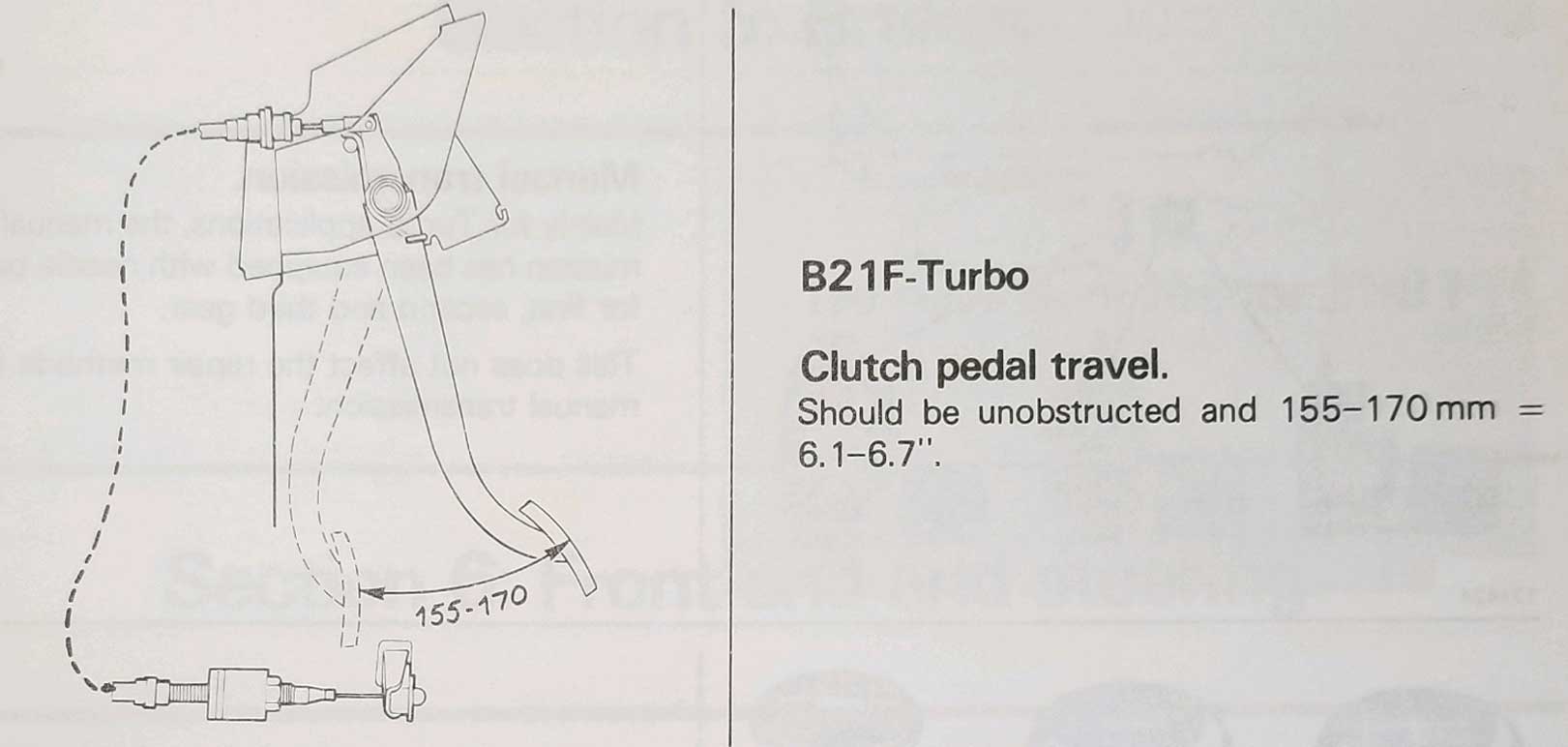

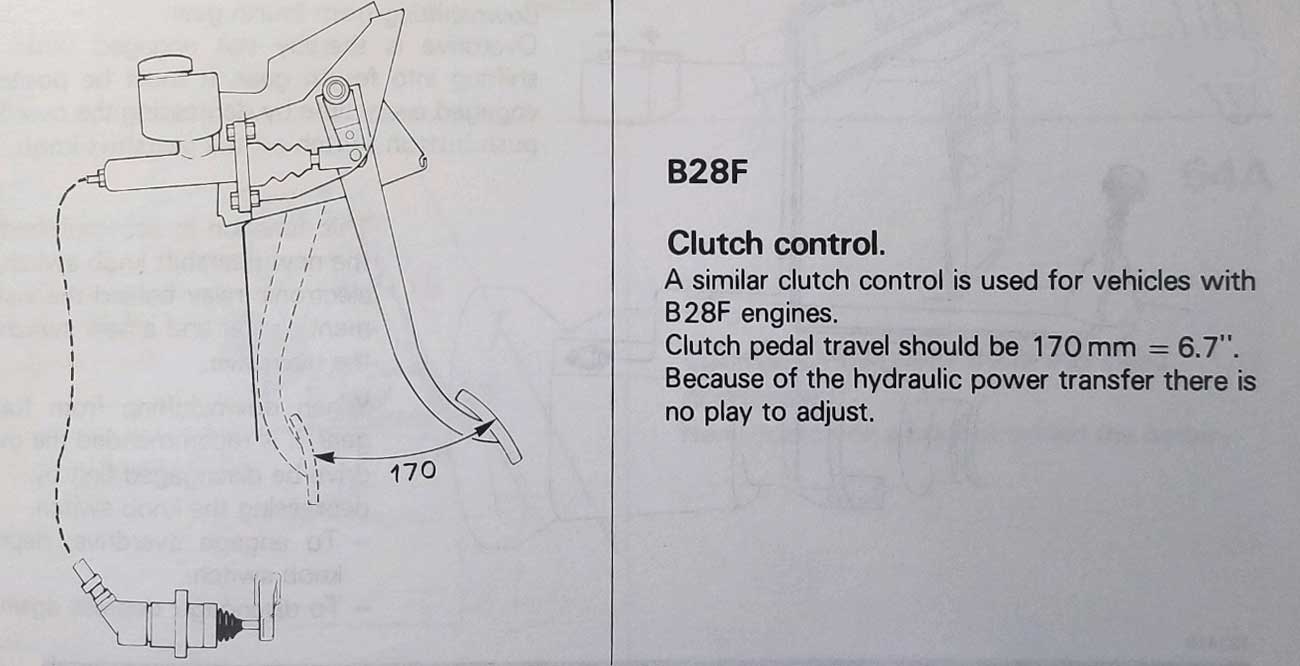

Short intermission to mention a hydraulic release bearing. I did not use one. Tilton (style) Hydraulic Release Bearing.  Here's a very lengthy TB discussion on this if you want more info. I don't have any of THIS in my page here. turbobricks.com/tilton-hydraulic-release-bearing.357178/ So why didn't I try this? Reason #1: That release bearing was a pretty unknown subject back when I did this conversion. Reason #2: I didn't want to be the one who posted this: "I had a lot of issues using these Tilton throwout bearings on Randy's flyin' moose car using M90 trans. We went back to the oem style and have never looked back." turbobricks.com/tilton-hydraulic-release-bearing.357178/page-3#post-6373384 Nowadays this type of release bearing may be something to reconsider. BACK TO THE TOPIC AT HAND Here are some CABLE CLUTCH diagrams from the 1981 New Car Features book.    And here is a diagram for the HYDRAULIC CLUTCH (below).  This image above suggests there is "no play to adjust" in case you need some adjustment. This is true with regard to the pedal, but there is always some adjustment available by spacing the clutch pivot ball closer to or further from the bell housing. The clutch pivot ball can be seen below CLICK HERE. 240 FIREWALL INFO Some firewalls have holes already, some do not. This is the LHD driver side firewall plate from a 240. The large lower hole near the bottom is where the steering column goes through. Most early 240s I've seen will have a metal cover, which is covering the position for a hydraulic clutch master cylinder, regardless if the car came with a manual or auto transmission. So converting an auto to manual or installing a hydraulic clutch master cylinder does not require altering the firewall if you have this plate. Some 240s, however, have a firewall plate WITHOUT the clutch holes.  Here's a LHD driver side 240 firewall plate that came WITHOUT any holes for clutch controls. If you have a 240 like this, you can trying finding a different firewall plate, however swapping this plate can be very time consuming, especially since it requires removing the steering column. The other option is to drill a few holes. A template is not needed. If you have a brake pedal box with a clutch pedal you can use the holes on that box to measure.  For some perspective, here's what the CABLE TYPE CLUTCH PEDAL looks like. For a hydraulic clutch, the clutch pedal must be changed to a hydraulic type pedal.   Here we can see where the holes need to be for the hydraulic clutch master cylinder. You can use the pedal bracket as a template to locate the holes and figure out precisely where to drill.   Learning some Hydraulic Clutch Basics If you're a beginner at this subject or if you want to learn more of the basics, I think you would benefit from watching the below 6-part series on Hydraulic Clutches 101. youtube.com/watch?v=m0bMac1 |

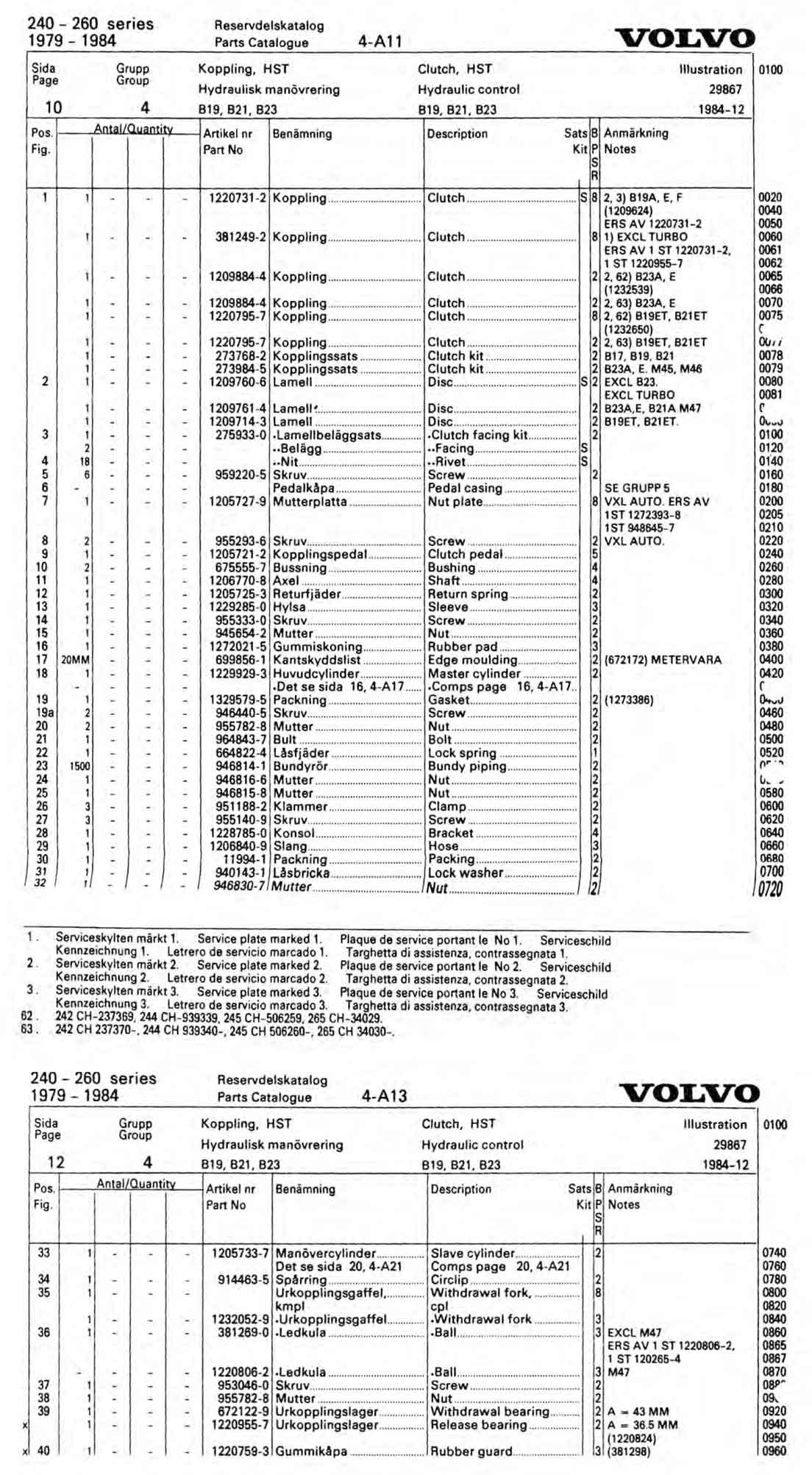

Now lets look at the basic differences between a cable clutch and a hydraulic clutch.

You'll see the above left photo again later, but I wanted to show how the Volvo bell housing will accommodate a pivot ball for EITHER a cable clutch or a hydraulic clutch. This allows for the cable to PULL a clutch fork when the pivot ball is in the cable clutch location. More bell housing info can be found here. And if the pivot ball is in the hydraulic clutch location, it allows the hydraulic slave cylinder to PUSH the clutch fork.  |

My conversion from Cable to Hydraulic was completed in 2011.

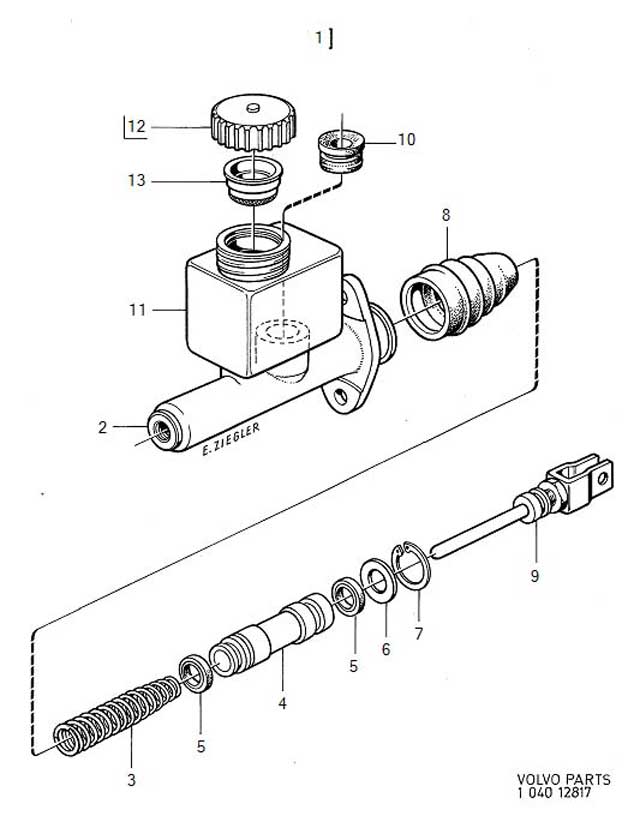

INTRODUCTION OF THE VOLVO 260 HYDRAULIC MASTER CYLINDER

This is the Volvo 260 clutch master cylinder I used, Volvo PN 1205729, manufactured by Fag. An aftermarket MC may be available as Centric PN 136.39000. It was used in the manual trans 264 in North America and in all manual trans 240 models in the UK and Australia because they were right hand drive. It was still available new when I started buying these parts in 2011. It still may be available. Or you might also find them used and I think rebuild kits are still available if you do. The inner bore/piston diameter is 19 mm (0.75 inch). The hose port on the rear is 12 x 1.0 mm Inverted Flare (double flare). This is quite different from the 10 mm Bubble Flare that Volvo used in all brake systems. It uses a metal hose like this photo below.

|

|

|

|

So then I

needed a clutch hose to mate the MC to a Slave Cylinder.

Back in 2011 I was able to locate a USED hose (like this one shown below). It had a hard line beginning at the master cylinder and it then transitioned to a flexible hose further down. I also chose the same slave cylinder seen in this first photo below. It was originally made for a 740, but it fits perfectly in the 240 since the bell housing is the same. Note the different looking clutch master cylinder below. That's a 740 MC, which used a clutch master cylinder without it's own reservoir. Instead this cylinder receives fluid from the brake MC reservoir, as you can see in the second photo below.   The length of this 740 clutch master cylinder is longer than the Fag MC for a 240. I thought it might be difficult to fit in a 240 (until I later saw this second photo above of someone who did it in that 240). So use your judgement. The body of this 740 clutch master cylinder is longer than the 260 FAG MC, so it will be a fairly tight fit in a 240. The hard line should be made to turn quickly so it clears the strut tower. This 740 Clutch MC is known as Volvo PN 8601785 (also 1273680, 1330248, 1330249). The inner piston/bore is 19 mm (0.75 inch) for the master cylinder (same for the slave cylinder). Same bore as the 240 Fag MC. If the outlet port is the same as the 260 FAG MC, then it'll be 12 x 1.0 mm Inverted Flare (double flare).   I have not found an official specification for the STROKE or length of travel of this MC, but in 2023 this thread below revealed that it's only 25 mm (1 inch), which is considerably shorter than the Volvo 260 Fag MC: 33 mm (1.3 inches). turbobricks.com/clutch-master-slave-cylinder-riddle.370314/ CUSTOM HOSE: If you decide to have a custom hose made by your local hydraulic hose shop, the original length of the pictured hose above is about 38 inches, but anything above about 30 inches will fit just fine in a 240. |

|

|

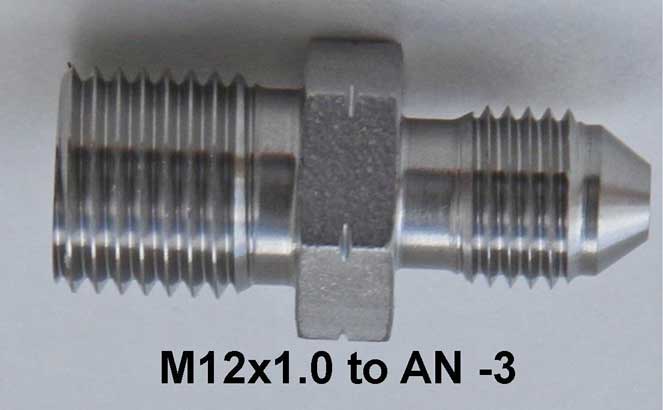

| Building your own clutch hose. An original Volvo 264 hydraulic clutch hose will not be easy to find.  This image above is a banjo adapter fitting which can be found online. It's thread size is 12 x 1.0 mm and it will fit the master cylinder outlet. It then uses the AN -3 end for the hose fitting. Search for "Steel M12x1.0 to 3AN banjo fitting". Optionally you can choose -4 AN hose, but for this info I will use -3 AN. Using a banjo fitting on the MC can help with a tight fitting master cylinder that has very limited room for the hose. Using adapters shown here you can either seek out a pre-made hose or build one yourself. A proper length can be 30 to 36 inches. If you buy the parts to build one yourself, choose a hose type that is rated for high pressure, such as this: pegasusautoracing.com/Product=3260 or https://www.summitracing.com/aer-fcc0303 These Stainless Steel Braided PTFE Brake & Clutch Hoses can handle 3000 psi. Here are some hose ends in -3 AN size: pegasusautoracing.com/productdetails=4154. Pegasus PN 3261-3-00 straight 3AN hose end. |

| THIS GUIDE WILL HELP IF YOU WANT A FLARED HARD LINE AT THE MASTER CYLINDER If you prefer a hard line like this below, you'll need to flare the pipe. So you'll need a flaring tool or someone who can flare brake line. This hard pipe is the same type of pipe as brake line, but normally this clutch line is larger than a typical 3/16 inch (4.75 mm) brake line you have one your 240, although you CAN use 3/16 inch if you like. A larger size pipe (shown below) can be 6 mm brake line. The flare type needs to be Inverted Flare (double flare), because that's what this MC requires. That hose fitting in this photo below is 12 x 1.0 mm for Inverted Flare (double flare).  If you use 3/16 inch brake line, you can use this flare fitting fitting at the master cylinder (1 needed): https://www.belmetric.com/double-flare12x1df475.html. If using a larger 6 mm brake line, you can use this one (1 needed): https://www.belmetric.com/double-flare12x10df600.html. Then on the other end of the hard line, which should transition to a flexible line, you can use a similar fitting, except in my opinion this end should be flared as a bubble flare (which is used in Volvo brake lines). That would mean this fitting is used (if using 3/16 inch line) (1 needed): https://www.belmetric.com/bubble-flare12x10bf475.html. Or this one (if using 6 mm line) (1 needed): https://www.belmetric.com/bubble-flare12x10bf600.html. This fitting can then be mated to an adapter, which will adapt the 12 x 1.0 mm flare fitting to an AN -3 hose end. This one will do it (1 needed): https://www.summitracing.com/parts/cst-sbh8069. So then the flexible hose will be AN -3 high pressure hose like this: https://www.summitracing.com/parts/aer-fcc0303 with a hose end like this on each end (2 needed): https://www.summitracing.com/parts/aer-fbm1100. |

| Here's a useful video showing how to assemble a hose like this. https://www.youtube.com/watch?v=5tdsgZ-KfWI |

|

|

|

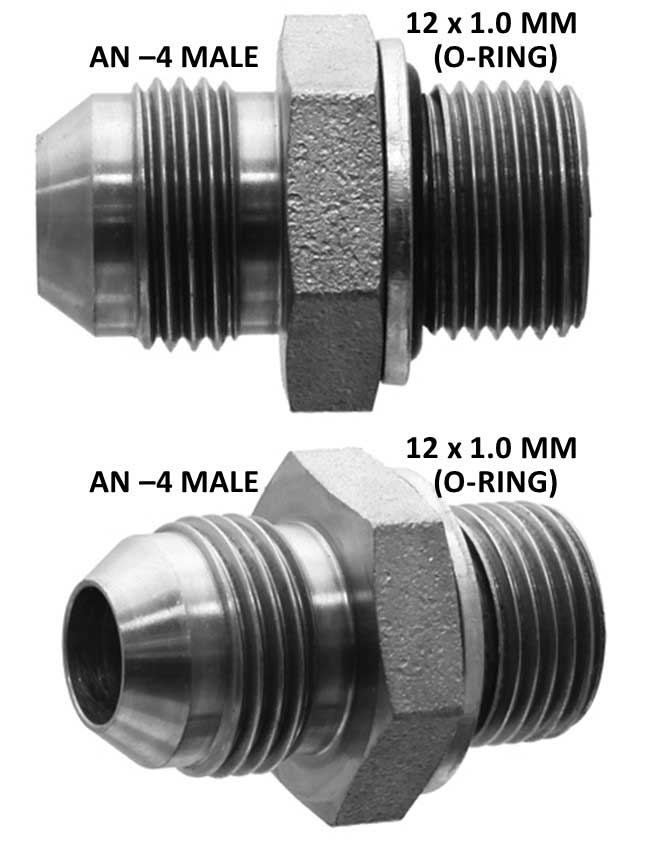

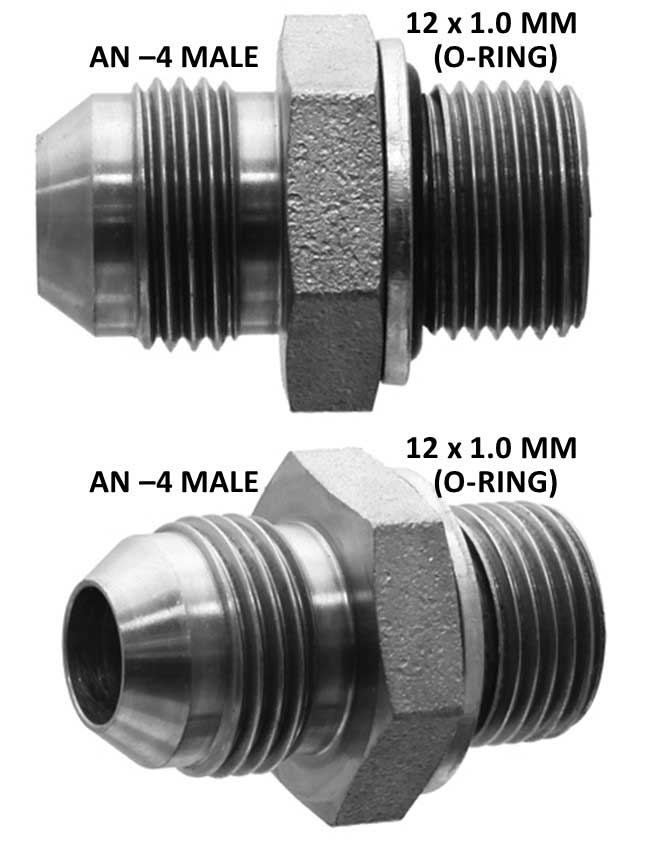

Here are some

adapters that will fit the 740 slave cylinder, which has M12x1.0 threads.

The hose side will use either AN -3 or AN -4

thread. You can search for "Steel M12x1.0 to 3AN adapter" or "Steel M12x1.0 to 4AN adapter".

Or something like this: https://www.summitracing.com/parts/ear-592053erl You should use a brass sealing washer on the M12 side (the side going to the slave cylinder). Or as a better option that I used, I suggest a metal-bonded sealing washer shown below.   METAL BONDED SEALING WASHERS  This is a metal-bonded sealing washer above. It has a rubber o-ring embedded in it. A sealing washer is generally used when a flare fitting is not used, such as on the M12 end of this adapter above. McMaster Carr has these washers: mcmaster.com/#standard-washers/, click "Sealing Washers," then "Metric High-Pressure Metal-Bonded Sealing Washers." Your local hydraulic hose shop may have them too. They can also be found at Pegasus Racing, called Stat-O-Seal Sealing Washers: pegasusautoracing.com/Product=3245 You might be thinking that hybrid washer above is inferior to an all-brass washer. You would be wrong. It can handle thousands of PSI and will easily out-perform the sealing capability of an all-brass washer. The custom clutch hose I had assembled in 2017 by a hydraulic shop can be seen a bit further below or CLICK HERE. |

|

|

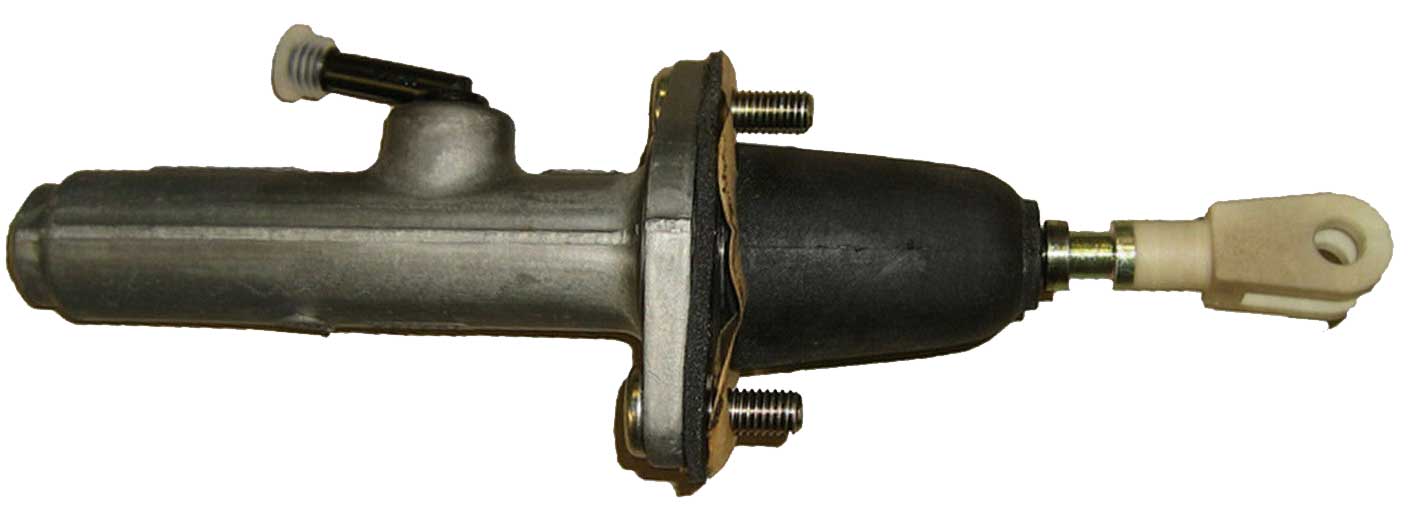

| The 740 slave cylinder is made to be a perfect

fit on a typical M46/M47 bell housing.

The circular mount on an M46 (or M47) bell housing is designed to hold either the cable end or this slave cylinder. This slave cylinder is Volvo PN 8601783 (older PN 6843913) and it came stander on a 740 with a manual transmission. This part (or an aftermarket version) is still available from a number of sources. The barrel outer diameter is stated to be 20.64 mm or 13/16 inch. It's retained in the bell housing mount with an external snap ring (shown further below).

Be aware there are some very early (pre-B21F) Volvo bell housings possibly for P1800s, 140s or early 240. Those have a different configuration and use a different type of slave cylinder. You're on your own with that type, since I have no useful info on that one. |

|

|

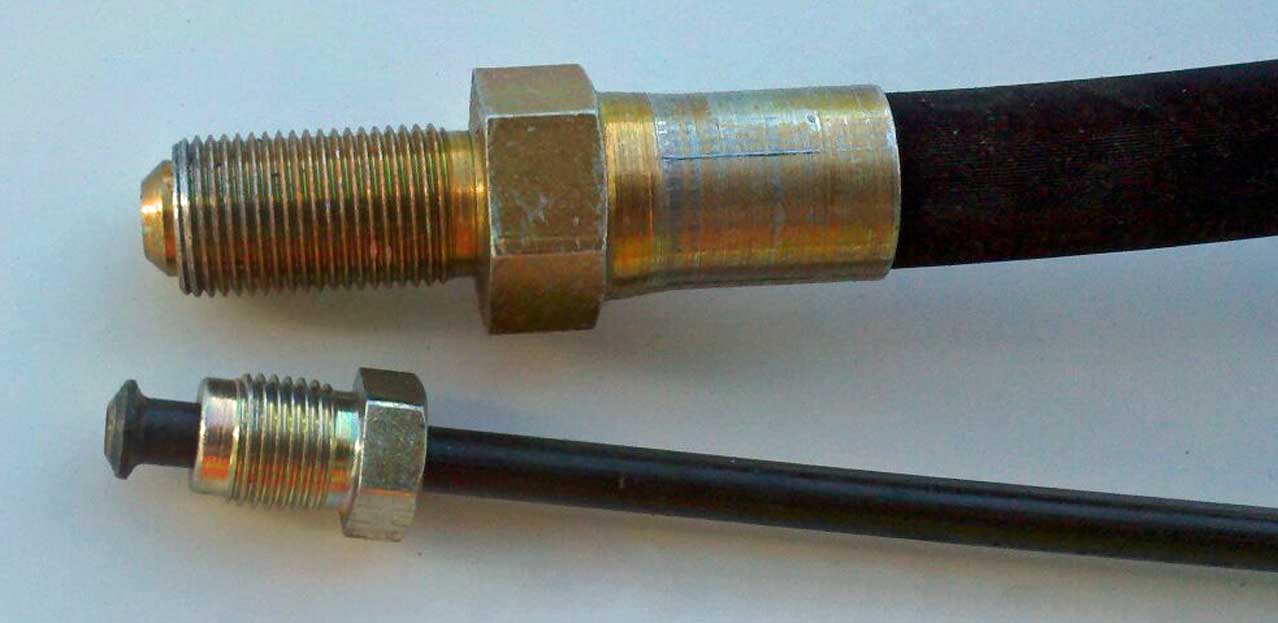

This 740 slave cylinder has an inlet port threaded 12 x 1.0 mm. It's machined at the bottom for a bubble flare (this different from the 240 FAG MC), so if you prefer, you can use a 12 x 1.0 mm Bubble hose end or adapter fitting. The face of the port is also machined flat, so you can optionally use a 12 x 1.0 mm fitting (or banjo) which accepts a sealing washer. This may be a brass, aluminum or metal-bonded sealing washer. The second photo below shows what the original hose end looks like for the 740 slave cylinder. This thread is 12 x 1.0 mm Bubble Flare. It's pictured next to a 10 mm 240 brake line for comparison.  |

|

|

|

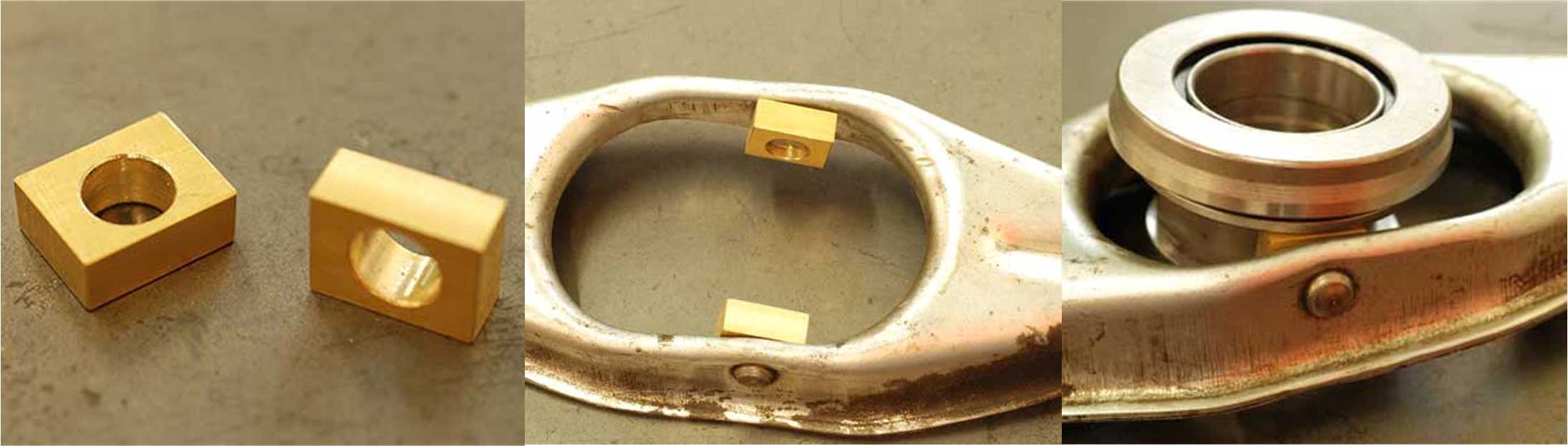

And you'll need this

external snap

ring (AKA: external circlip or retaining

ring) to keep the slave cylinder locked in the

mount on the bell housing.

It's Volvo PN 914463 (part number for 740 part). Inside diameter is 30 mm (same as 1 3/16 inch or 1.187 inch). |

|

ALTERNATE FORK

There is an alternate fork available which has a depression on the end instead of a hole. Volvo PN 3549983.  |

|

CAUTION: If you have clutch fork 1220763, be careful of

this little PLASTIC END CAP found on the push rod on the Volvo slave

cylinder.

If your clutch fork has a HOLE in it, like this one does, where the plastic end on the push-rod pushes, you could experience a failure like I did.

|

|

One

minute you have a nice working clutch. The next

minute your pedal goes to the floor! Because of THIS.

The white plastic end cap sheered and the push-rod went right through the hole in the fork. |

| So I then drilled that hole out in the hole in the fork slightly and installed a large socket head bolt in there. Now the end of that rod rests in the center of that socket head.   |

|

|

|

|

|

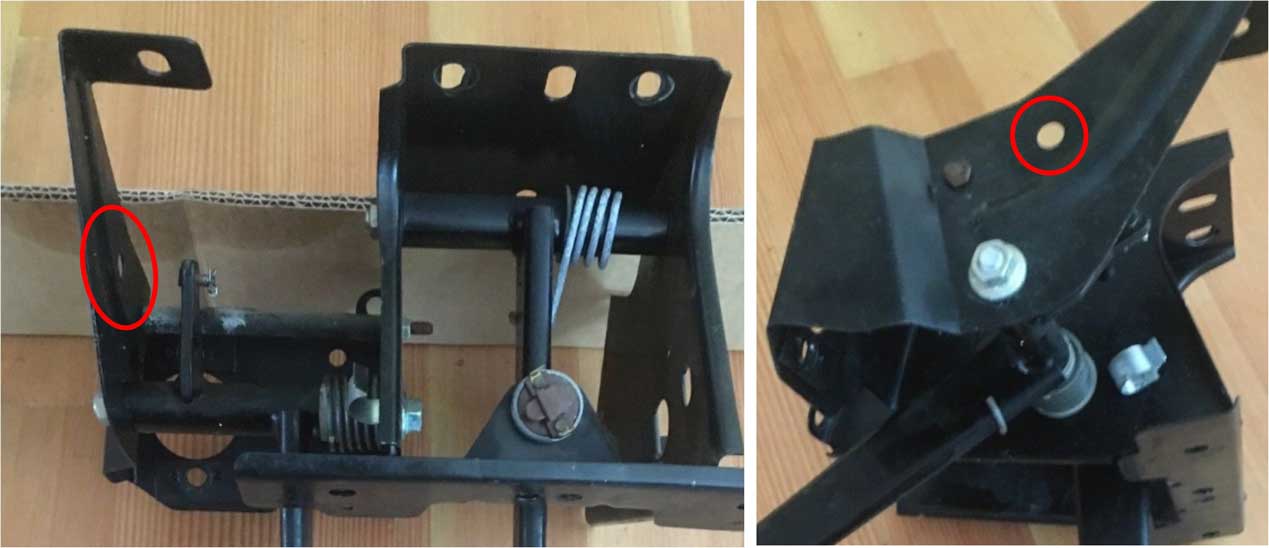

Converting

from a cable to hydraulic clutch requires that you

have a compatible bell housing.

These TWO photos below show a LATER TYPE M46 or M47 bell housing. One part that gives it away as a later type is the opening at the top of the bell housing (top-left in this first pic below) for a crank position sensor, which came on 1989 and later cars. That's not really important for this discussion. Just a bit of trivia in case you need that port for a crank position sensor.  You won't necessarily need a bell housing that has an opening for a crank position sensor unless you're using an engine management system that requires it, such as LH 2.4. The important thing is that the bell housing should have the second pivot ball mounting hole for a HYDRAULIC CLUTCH FORK. There are some early (pre-240) M46 bell housings that do not have this second hydraulic mounting hole. |

|

|

Here are some close-up images of the back side of the hole for the hydraulic pivot ball. The head of a bolt will fit in there.  There is more than one style of pivot ball. Below: One is short and one is tall. The threaded hole in the rear is M8-1.25.   Volvo PN 6814409 (tall) is listed by Volvo Classic Restoration as for 1979-92 cars. classicvolvorestoration.com/pivot-pin-clutch-fork-240-79-92 Volvo PN 3549638 (short) is listed for 1993 and later cars. classicvolvorestoration.com/pivot-pin-clutch-fork-volvo-240-74094093 I think you could probably use either type. If it needs to be longer, a spacer or washer could be placed under it. |

|

|

| When I first installed an M46 and then a T5 I used a CABLE Type Clutch Fork, so I'll show that first. The standard Volvo clutch fork is used with a Ford Mustang style clutch release bearing. The fork required some special metal pieces to be added to properly support the Ford T5 bearing. These are really old photos below from 2004.  Here are some better photos below of the new parts that are now offered by BNE Dynamics for a cable type fork.  These special pieces are available from BNE Dynamics: bneshop.com/throwout-bearing-for-t5 The McLeod 1600 release bearing (throw-out bearing) is equal to the standard Ford T5 bearing. The McLeod 16515 is an alternate adjustable version you can find in the BNE page. Either of these bearings can be used with a Ford T5 in a Volvo for use with a cable fork or hydraulic fork.  Comparison: Cable and Hydraulic Clutch Forks. The top clutch fork is a typical cable type. The bottom one is a typical hydraulic type from a 740. Any typical 740 clutch fork is perfect for this project. Volvo 740 part numbers that should work: 3549983, 1220763.  |

|

|

|

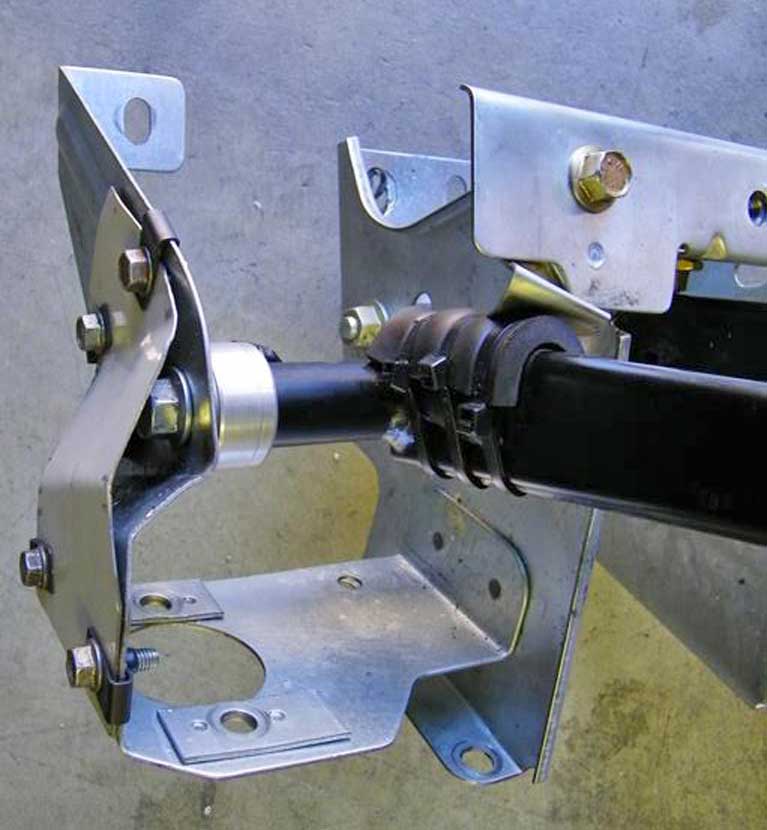

I found a used Volvo 260

hydraulic clutch pedal and fitted it into my

existing manual trans pedal box.

A hydraulic clutch pedal is about 50 mm longer than the cable pedal (between the pedal and pivot) because it mounts into a different set of holes in the pedal box. The hydraulic pedal holes are higher up. The holes will normally already be in the pedal box. My pedal box had the holes needed.   |

|

|

Here is where

the holes are found for mounting the hydraulic pedal. It's mounted higher up in the pedal box.

|

|

|

|

There are some Turbobricks threads in which

people have made their own hydraulic pedals or

they have modified a cable type pedal to work. That sort of work was beyond my

skills.

Here's a thread about one that was custom made: turbobricks.com/not-mediocre-242.326370/page-6

|

| As of May 2018 STS Machining is offering new aluminum hydraulic clutch pedals: stsmachininginc.com/240-hydro-clutch-ped

|

2017: Changing to a different Master Cylinder

|

After about 6 years of use, the new Volvo 260 master cylinder shown here began to

fail. The piston seal began leaking fluid

out of the back when pushing on it.

This might have been due to the heavy clutch I had, but it could also be because this was a 30 plus year old NOS part when I bought it. I could have rebuilt it, but I thought the chance of this happening again was probably high. So I decided to try a different master cylinder. There are a number of choices. I'll show you a few I considered below. Whichever master cylinder you choose, be sure to consider the inner piston size. Most aftermarket master cylinders will give you several size choices. The Volvo Fag 260 MC has a 0.75 inch (19 mm) inner piston. That's the size I would be looking for initially (but if you read further down, you'll find out I later changed my mind for my clutch situation). |

||||||||

|

|

||||||||

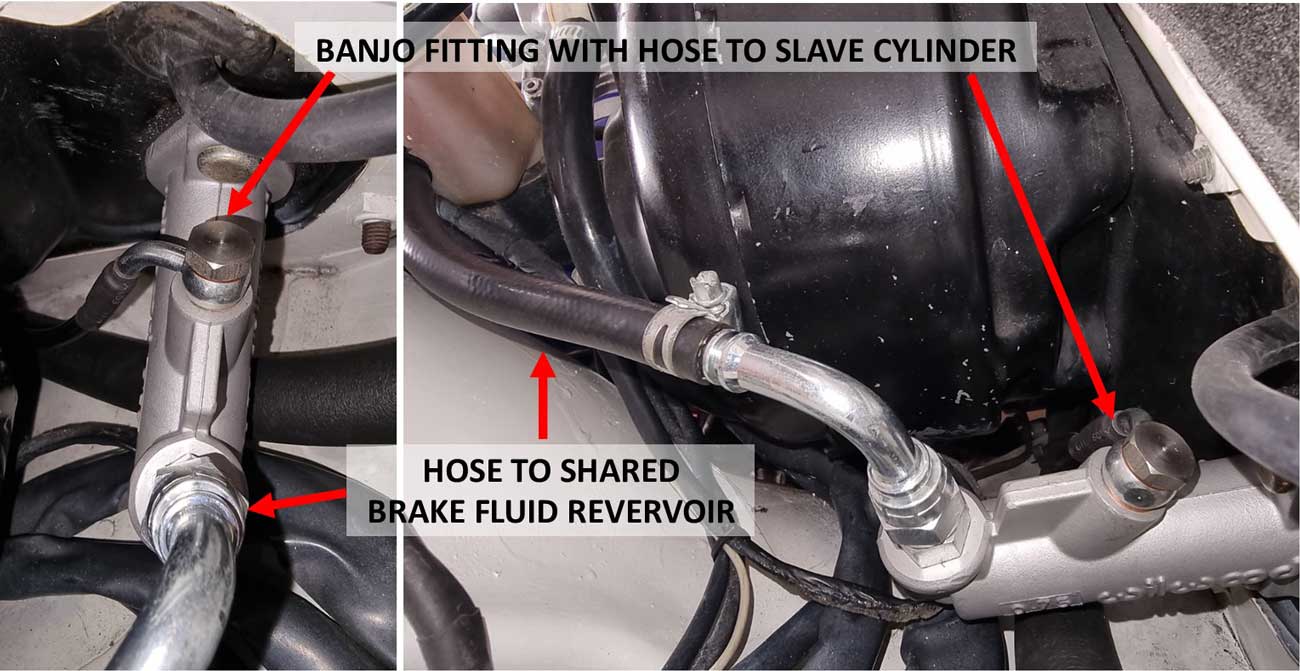

A master

cylinder like this one below from Wilwood may be a

good choice.  The MC is certainly short enough to fit in a 240. It's very similar to early Volvo master cylinders used in Volvo 122 Amazons. I did not prefer the hose outlet being on top like this. It makes bleeding more difficult than something with a hose sloping downward toward the slave cylinder. When bleeding a hose that rises above the master cylinder, air will get trapped in there. So when bleeding, it can be hard to get that air out. If you have someone pushing the pedal while you're under the car opening a bleed valve, it can be frustrating. This can more easily be solved with a power bleeder, which is shown further below. A power bleeder has the ability to push a lot of fluid through the hose under constant pressure to overcome an air bubble. If I had chosen a master cylinder like the Wilwood shown above, an alternate solution would be a 90 degree fitting on the outlet for the hydraulic hose or maybe a banjo fitting similar to the below images.  Here are a couple images above from Aris 240 (from Greece). In 2023 he installed this Wilwood Compact Remote master cylinder PN 260-6089 for his clutch. It's made for a remote reservoir style MC and in this installation it shares fluid with the brake fluid reservoir from a 740. Aris' 240 build info is detailed in the following forum discussion (go to Post #136): https://turbobricks.com/index.php?threads/the-build-story-of-a-greek-hopefully-fast-240-brick.310632/ A benefit of this style of master cylinder is that it offers a stroke of 1.4 inches (35.5 mm). This is more than the Volvo Fag 260 MC, which has a stroke of 1.3 inches (33 mm). Volume area: 0.57432 sq.in. The TILTON 75 compact MC (shown below MIDDLE) only has a 1.1 inch (28 mm) stroke. With bore of 0.75 inch, the volume area is 0.48597 sq.in. This shorter STROKE info became more important later for my car. You'll see if you keep reading. |

||||||||

|

|

||||||||

|

||||||||

| When it came time to replace the Volvo Fag MC, I chose the Tilton

75 Series below with a .750 inch (19 mm)

piston. While installing it I discovered that there was a new problem. There always is, isn't there. The 240 firewall sheet metal (just above where the master cylinder mounts to the firewall) interfered with the reservoir. It's because the reservoir on this style master cylinder is positioned very far to the rear and you can see it's very close to the firewall mounting flange. Basically the reservoir hits the firewall before the mounting flange does. PHOTOS coming up further below.  The outlet port is threaded for 3/8-24 female, which is the same as AN -3 thread.  |

||||||||

|

|

||||||||

One solution for this firewall interference could be a remote reservoir. I didn't seriously think that was a good option, however after completing my project I found this photo above of a similar Wilwood compact master cylinder with a remote reservoir fitting. So it can be done. More on the thread where this photo came from can be found at turbobricks.com/lm7-t56-into-a-82-245.335335.  Or it's also possible to fit a 740 brake master cylinder with a side port to feed the clutch master cylinder. This 740 clutch MC WOULD NOT have worked for my car because of the internal stroke length. This one is too short for my use at only 25 mm (1 inch). |

||||||||

|

|

||||||||

| FIXING THE FIREWALL

CLEARANCE PROBLEM with SPACERS: So my solution was to use a couple 1/2 inch thick round spacers and some longer bolts I had on hand. Not the most elegant solution, but it gets the job done just fine and the mounting at the firewall is still very solid. Problem fixed. I had originally hoped to find a 1/2 inch spacer shaped similar to the mounting flange so I could move this master cylinder 1/2 inch forward. Such a spacer did not exist when I was searching and making one was too much work.   |

||||||||

|

|

||||||||

| Then it was time to have the new hose made. I

took the master and slave cylinders down to a

local hydraulic hose shop, along with the adapters I had. Keep in mind that most hydraulic hose shops are there to hydraulic make hoses for heavy equipment. They may not be experienced with automotive or hot rod stuff. Some places are.

There are a number of ways to make a hose for these components. Lots of options exist. If you know specifically what fittings YOU want, discuss that with them. Try to be patient and have as much info for them as possible. Hose detail: fitting to Tilton Clutch MC: The Fag-Volvo 260 MC I previously used and the 740 slave cylinder both have a thread pitch of 12 x 1.0 mm female. Now I have an MC with a completely different thread. This Tilton MC has 3/8-24 female threads, which is the same as AN -3. The port outer face is machined flat in case you want to use a banjo fitting or an AN -3 fitting which uses a sealing washer. Those are options to consider. I went a different route.

The Tilton MC came with some adapter fittings. One was that gold-colored double male AN-3 flare fitting in the photo above. The hose shop I went to had commercial JIC fittings and high pressure -4 Golden21/ISO 3000 psi flexible hose. They used that gold AN -3 double male flare fitting along with another adapter fitting they supplied, which stepped up the AN -3 to AN -4. Then they mated a new hose end to the AN -4 hose. This new hose end was a 45 degree JIC (AN -4) female swivel fitting, which can be seen above. That completed the MC end. Hose detail: fitting to 740 Slave Cylinder: On the slave cylinder end the hose shop supplied a Male JIC 7/16-20 (equal to AN -4) to 12 x 1.0 mm O-Ring adapter, which is shown below. The 12 x 1.0 mm end goes into the clutch slave. The O-Ring I used was a metal-bonded sealing washer.   The above adapter would then mate to a new hose fitting they crimped onto the AN -4 flexible hose. This new hose fitting was a JIC 7/16-20 (equal to AN -4) STRAIGHT female swivel fitting, which can be seen in the hose photo above. The total length of the new hose when completed was about 38 inches. Cost was about $60.

|

||||||||

|

This is a metal-bonded

sealing

washer.

It has a rubber o-ring embedded in it. It's generally used where a flat sealing washer is required or when a flare fitting is not used, such as on the M12 end of this adapter above. McMaster Car has them: mcmaster.com/#standard-washers, click "Sealing Washers," then "Metric High-Pressure Metal-Bonded Sealing Washers." Your local hydraulic hose shop may have them too.  You might be thinking this hybrid washer above is inferior to an all-brass washer. You would be wrong. It can handle thousands of PSI and will easily out-perform the sealing capability of an all-brass washer. |

||||||||

|

|

||||||||

| This clutch push rod needed some

changes. For my use it needed to be shortened almost 1/2 inch compared to when it was used with the 260 master, even with the 1/2 inch MC spacers at the firewall shown above. The threads on this thing allow for a small adjustment, but for the adjustment I needed, that forward rod had to be shortened a small amount (maybe 1/8 inch) using a bench grinder.

|

||||||||

|

Installation

completed.

|

|

|

|

ANOTHER Master Cylinder Change.

Update: June 2017 The piston stroke for the

Volvo 260 Fag master cylinder is about 1.3 inches (33 mm). Volume area: 0.57432 sq.in.

The Tilton 75 Series MC with 3/4 inch (19 mm) bore has a stroke of only 1.1 inch (27.94 mm). Volume area: 0.48597 sq.in. This presented a problem in my car and it turned out I was not getting as much pedal stroke in the master cylinder as before. So after installing the above Tilton MC, the clutch wanted to disengage very close to end of the pedal travel near the floor. I didn't like that. I needed a bit more stroke, but the Tilton 75 master cylinder is not available with a longer stroke.  The Wilwood version of this MC is the same. So I changed to a Tilton 75 with a larger bore SHOWN ABOVE, 13/16 inch (20.64 mm) bore instead of 3/4 inch. New volume area: 0.58802 sq.in. The new one is the fatter MC shown above. Adding that extra 1/16 inch (1.59 mm) to the bore adds about 17% more volume in the stroke. It's equal to increasing the stroke from 1.1 inches to about 1.3 inches, which virtually gives it the same volume as the Volvo FAG master, which had 0.57432 sq.in. That corrected the problem. If you can add to any info in this page,

please email me.

|

|

|

|

MOTIVE POWER BRAKE BLEEDER

When it comes time to bleeding brake or clutch hydraulics, nothing beats the Motive Power Bleeder. I won one of these many years ago at a Davis Volvo Meet raffle and it has served me well for years and years. DIY bleeding with no need for a helper. Perfect. It's about $50 for those who aren't raffle winners.

RESOURCES:

AN Thread Wikipedia: https://en.wikipedia.org/wiki/AN_thread Automotive Fittings Explained: http://www.speedwaymotors.com/the-toolbox/automotive-fittings-explained/28780 Useful discussion treads: turbobricks.com/wilwood-clutch-master-cylinder-for-my-242.100636 turbobricks.com/making-your-cable-clutch-hyrdaulic-in-your-240.149175 turbobricks.com/240-hydraulic-clutch-conversion.234399 turbobricks.com/critique-my-hydraulic-clutch-set-up.325285 turbobricks.com/converting-cable-trans-to-hydraulic.320417 |

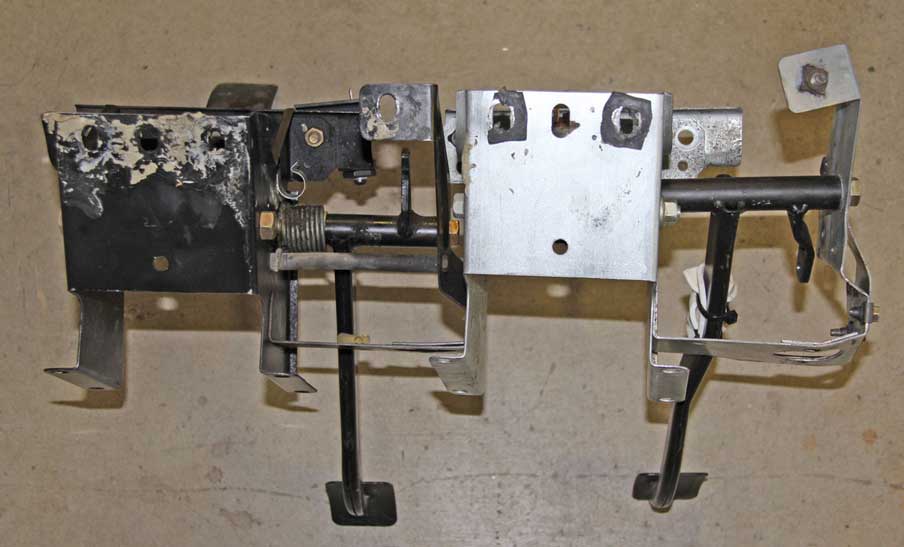

Removing or Swapping the Pedal Box

Swapping the pedal box can be a pain, but it's so necessary for this stuff. If you have time, I prefer removing the dash so access is so much easier. It can be done without doing that, like this write-up, but it can take some extra patience.

This write up in TB shows how this swap was done from auto to a manual pedal box (with hydraulic clutch) in a 1991 240.

turbobricks.com/hydraulic-manual-swap.372737/

| Fixing

a Bent or Mangled Clutch Pedal Box I had to do this twice! |