| 240 Headlight RELAY Page |

|

UPDATED: January 14, 2024 CONTACT

|

D O M

A I N S   |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

If you have any comments or if you can improve this information, please feel free to email.

CONTACT

| Before 1975 (before the 240) This early headlight step relay was used in the 140 model for headlight control and 1800 models for overdrive control. It's function is similar to the headlight step relay shown below. More about this relay can be found in Ron Kwas' page: https://www.sw-em.com/Headlight_Notes.htm#Bistable_Control_Relay  |

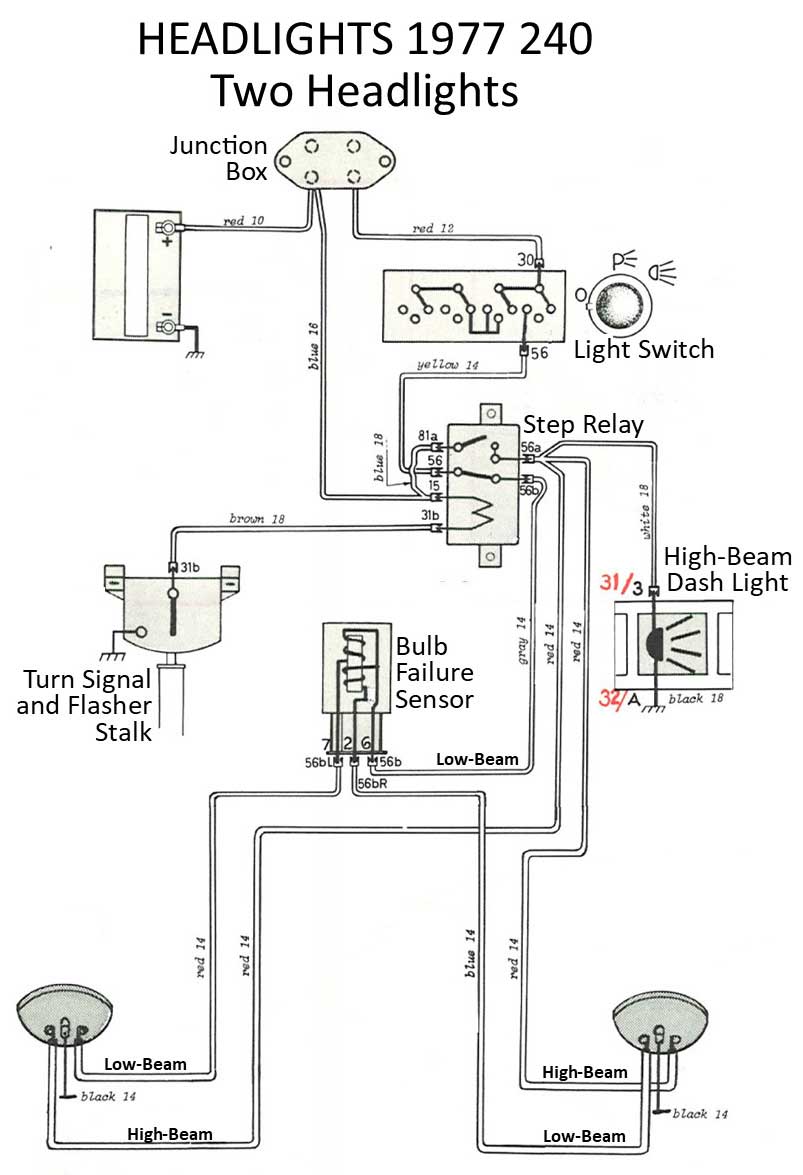

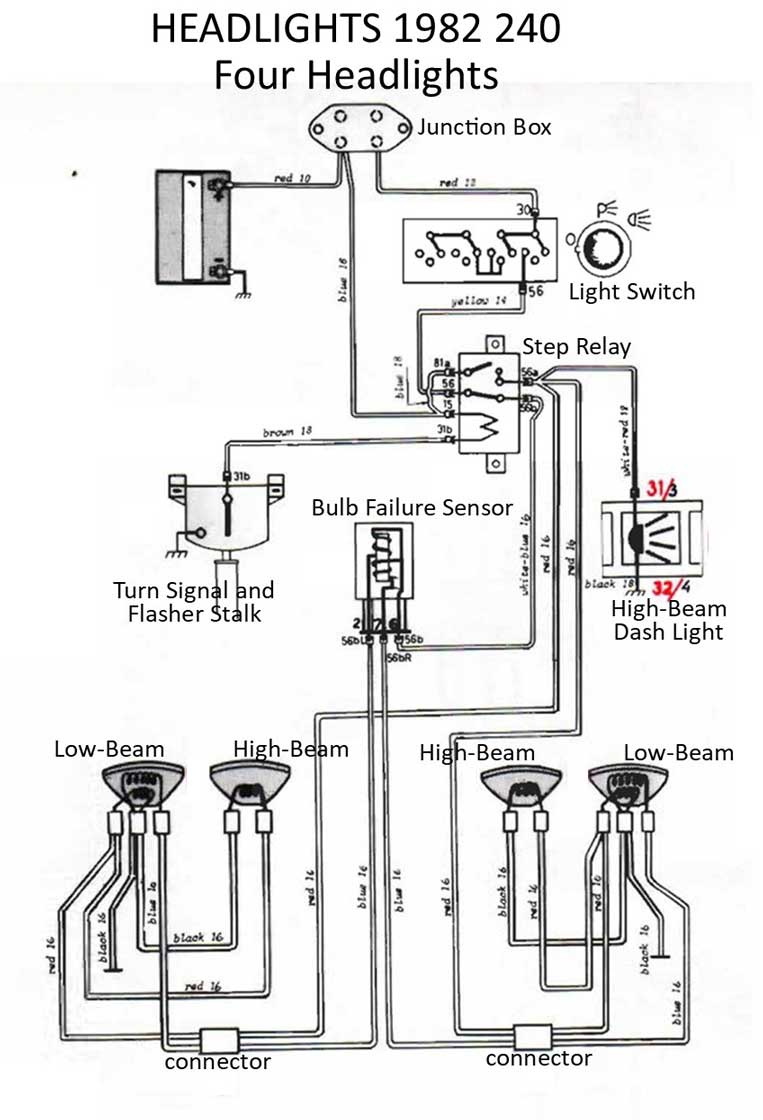

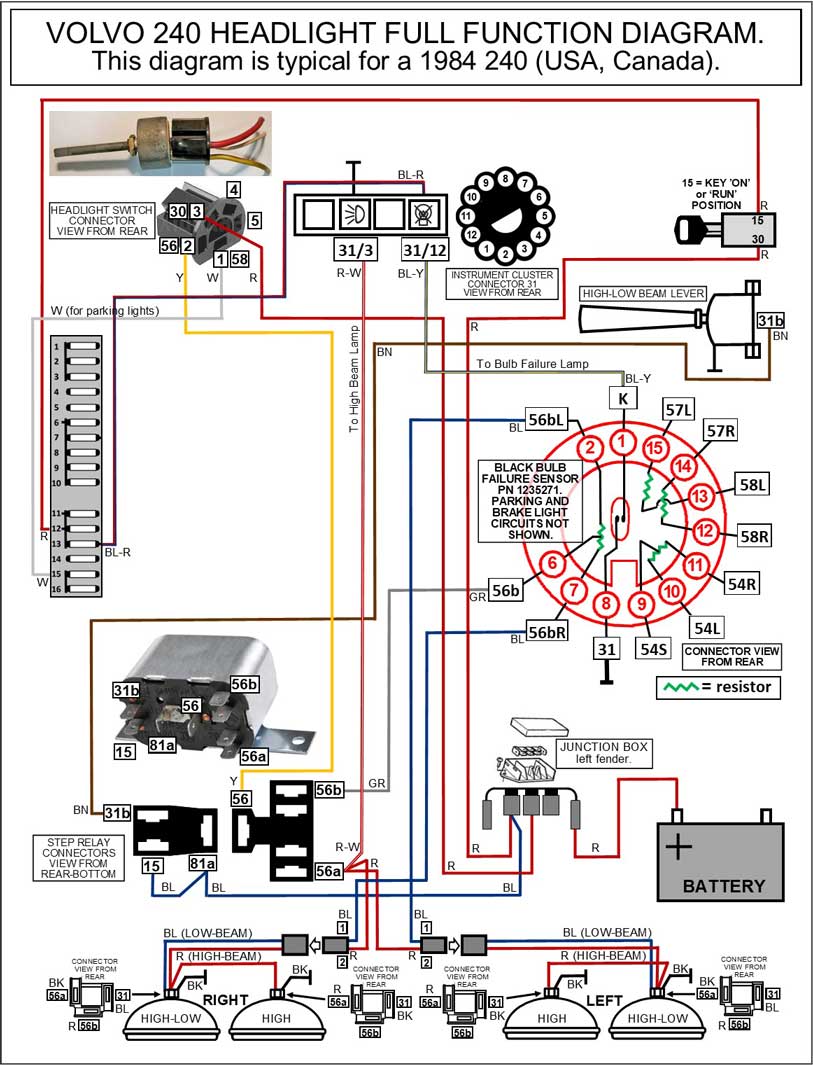

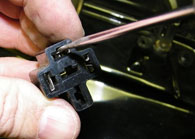

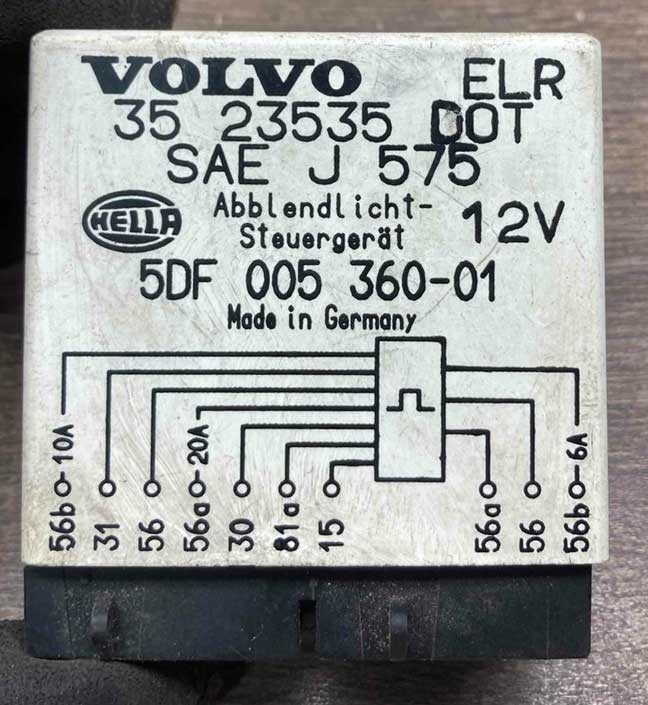

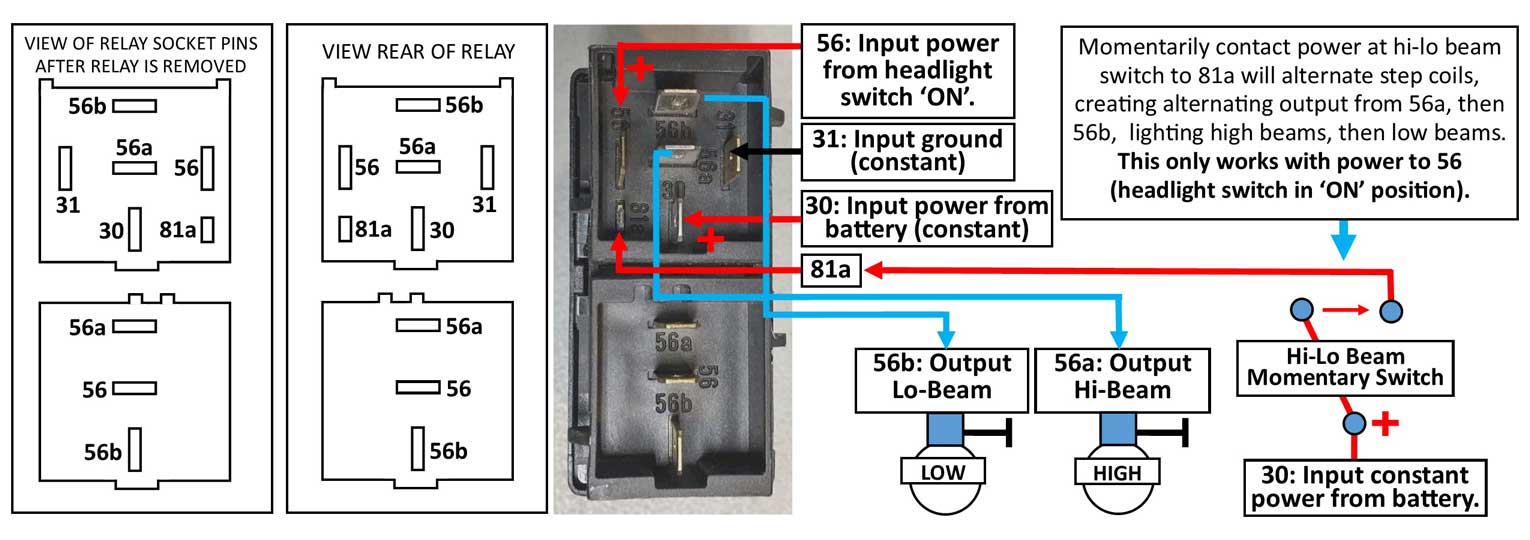

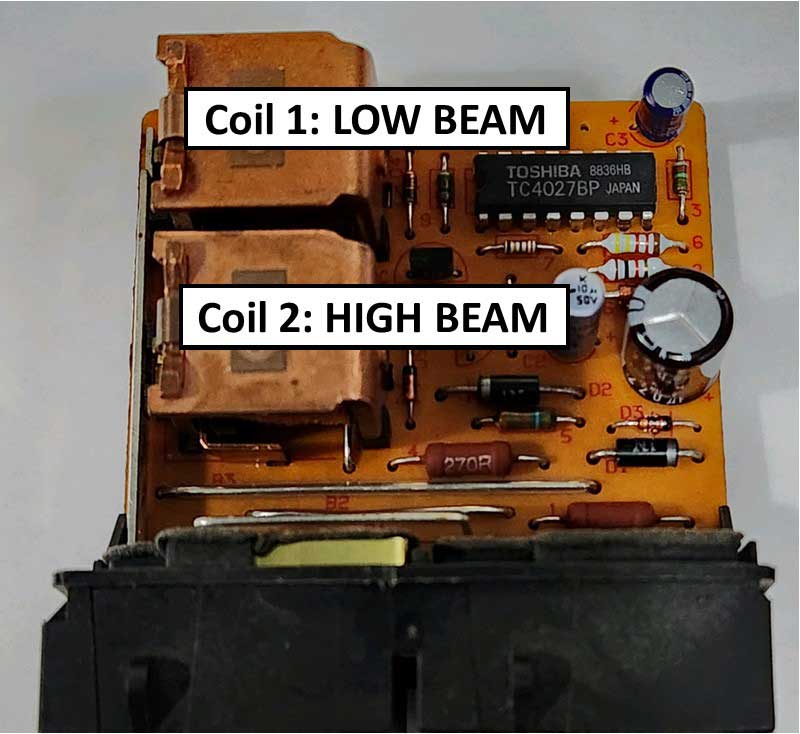

| 1975-85 240 This headlight relay was used in these early 240s. It's function is to switch (or step) between low beams and high beams. It's a big relay and it makes a loud "clunk" when it switches. It's generally a very reliable relay. The internal function of this relay is COVERED IN DETAIL HERE. PN 1307991 Headlight Step Relay.   Sometimes these relays fail. I had one fail one time many years ago. The failure was an internal soldered junction that broke, which disabled low beams. I was able to disassemble it and I repaired it with a soldering iron. |

|

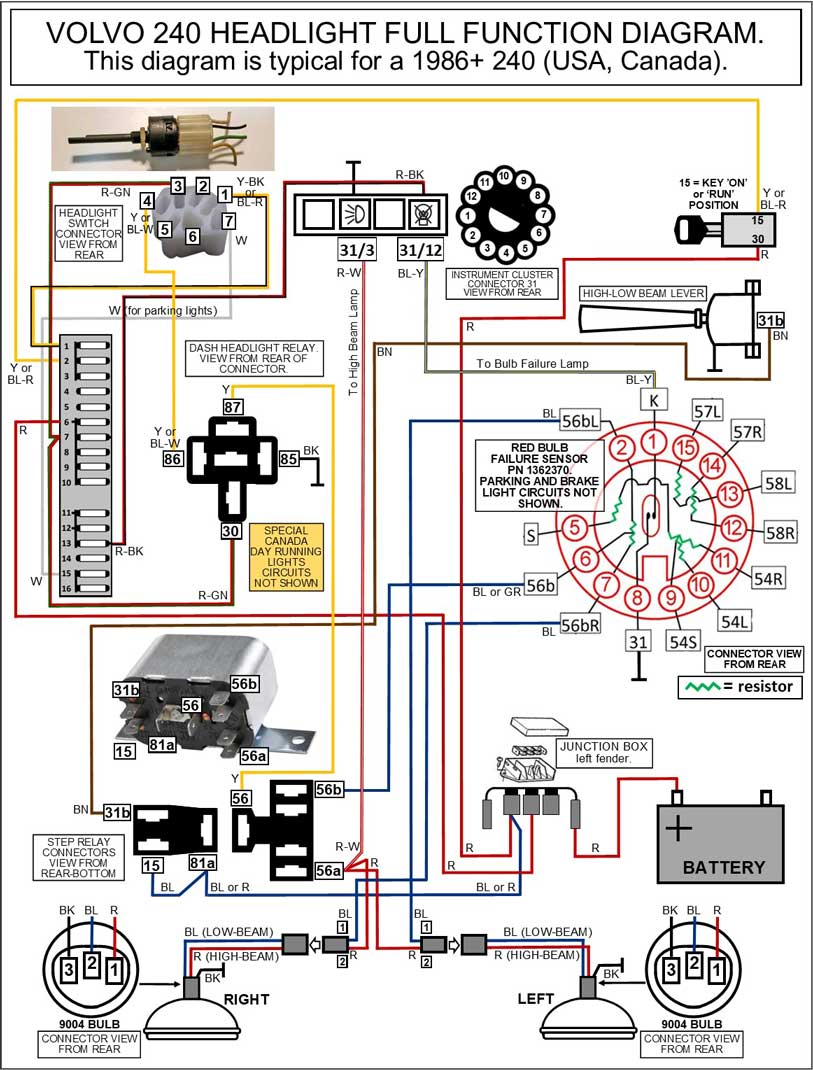

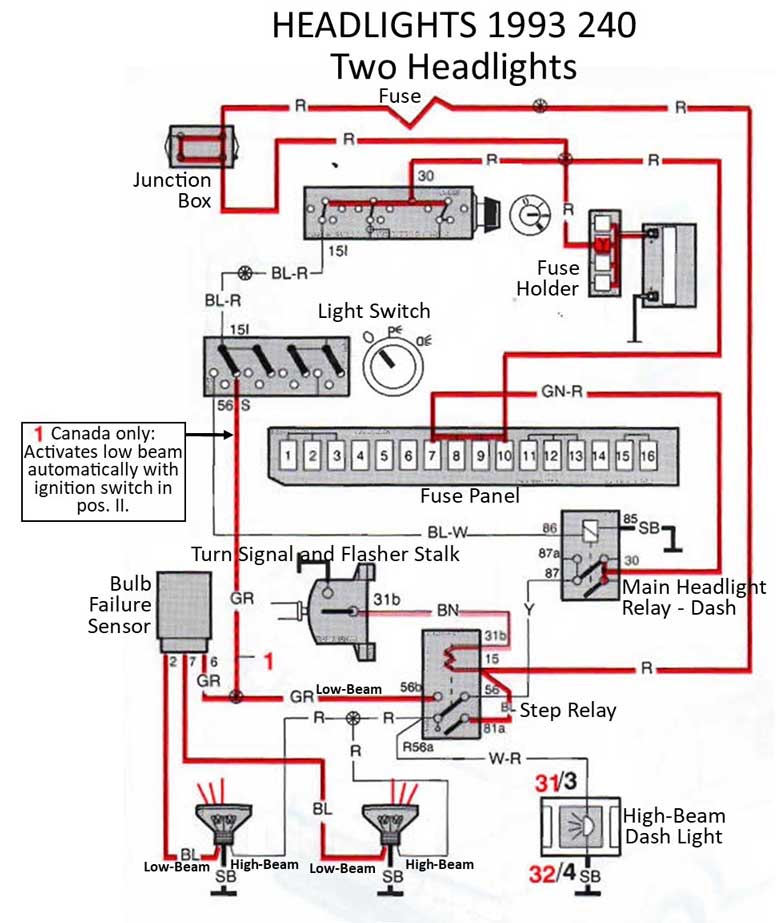

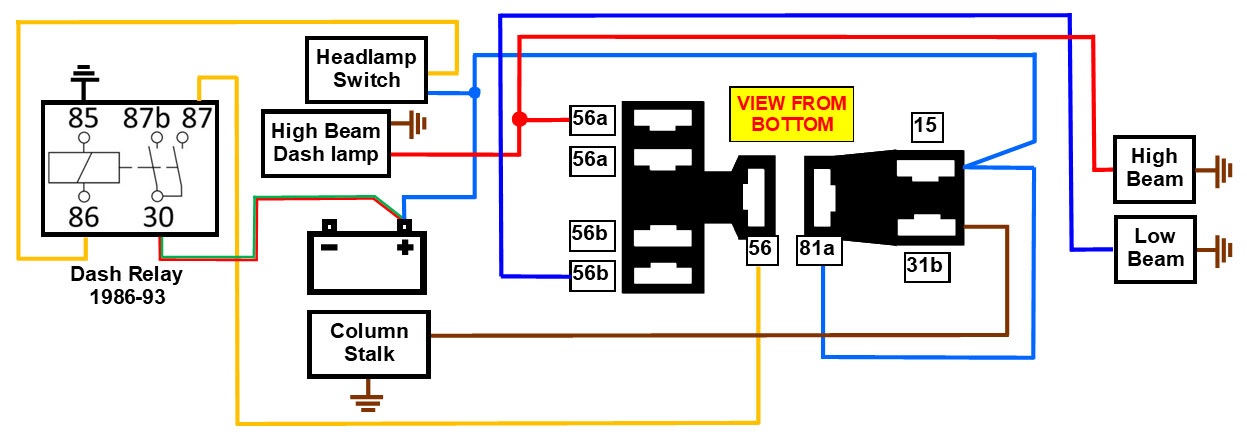

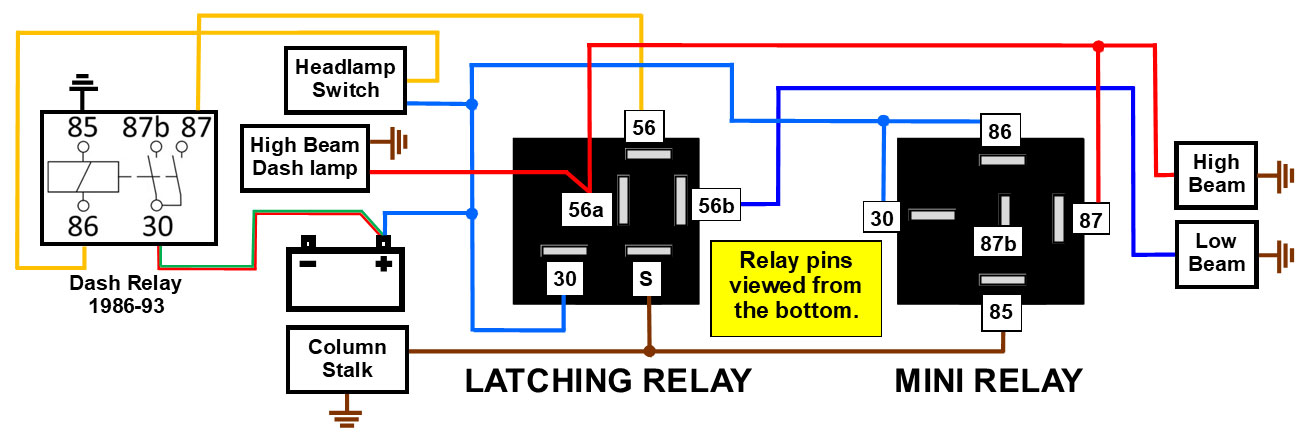

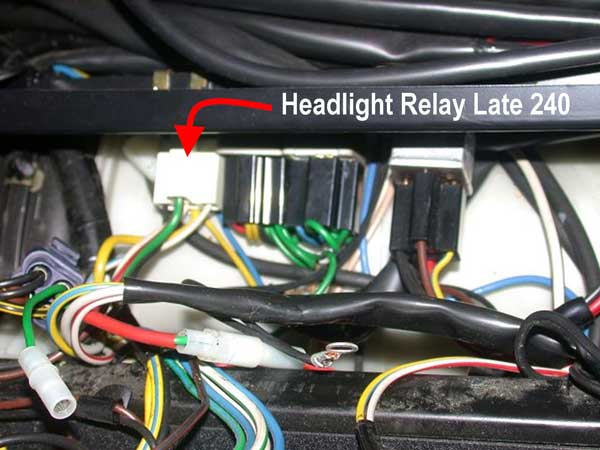

1986-93 240

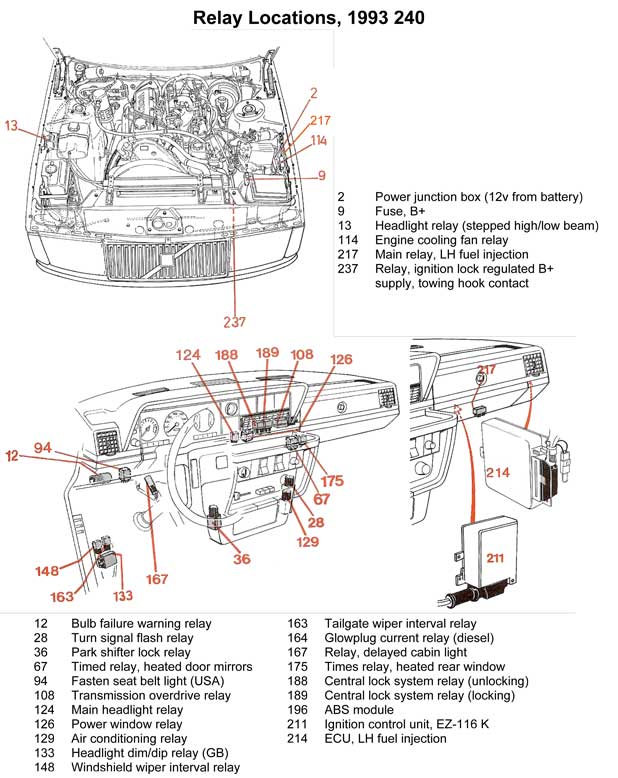

Later 240s beginning in 1986 also got the 1307991 step relay, but these cars were also fitted with a new "MAIN" (in-dash) HEADLIGHT RELAY.  Here's a look at the main headlight relay in the 240 center dash. This relay is found NEXT TO and to the LEFT of the POWER DOOR LOCK RELAYS, which can be seen in this photo above. This photo was taken with the entire dash removed. Removing the dash is not necessary to access these. You should be able to get to these relays by removing the center air vents and by pushing the inner plastic air duct out of the way. Or by removing the center dash console as shown in the below VIDEO. No, Volvo didn't make it very easy to access these. 240 Relay Locations PDF below (1993 diagram). Look for Relay 124 Main Headlight Relay.

|

||

|

||

|

| ANTI-CORROSIVE

ZINC PASTE (ACZP) If we can just just keep our electrical connections clean and tight, almost all of the electrical issues would be gone forever. That would be nice, right?   I

have owned a number of Volvos

over the last 35 years and my

current 240 is 40 years

old. It almost never has

electrical problems. Nothing

like the endless numbers of

other 240s out there that I hear

about so often. What's the

difference you ask? The

main difference is that my 240 has

been always garaged all of its

life. Why is that

important? Because leaving

any car out in the open elements

for years and years slowly

introduces corrosion to grounds

and power connections until

things begin to go wrong. I

have owned a number of Volvos

over the last 35 years and my

current 240 is 40 years

old. It almost never has

electrical problems. Nothing

like the endless numbers of

other 240s out there that I hear

about so often. What's the

difference you ask? The

main difference is that my 240 has

been always garaged all of its

life. Why is that

important? Because leaving

any car out in the open elements

for years and years slowly

introduces corrosion to grounds

and power connections until

things begin to go wrong.

So if you own one of those cars that has been outside forever, it's not too late. You can still clean as many grounds and electrical connections as possible. And while you're at it, I strongly recommend that you smear a little anti-corrosive zinc paste on those connections. Many people in the Volvo community are already familiar with Ox-Gard, which does a very good job. The below information was contributed by Ron Kwas and should come in very handy to old Volvo owners: Anti-Corrosive Zinc Paste (a generic name for zinc dust contained in a grease) was originally developed for and later required by electrical codes for use on aluminum to copper electrical connections (or other dissimilar metal connections). No, it's not the same as Dielectric Grease, which is often incorrectly recommended. Dielectric Grease can offer some protection in the form of encapsulation from moisture, but it also carries with it the potential disadvantage of locking in moisture or existing corrosion which may have already begun forming. Anti-Corrosive Zinc Paste (ACZP) is the next evolution of the encapsulation principle, because zinc (the lowest on the Galvanic nobility chart) neutralizes corrosion on a micro-scale to truly protect connections on a long-term basis during the encapsulation, INCLUDING an added protection from corrosion which may have begun to form in that connection. Ron Kwas uses and recommends Penetrox A (by Burndy). Many Volvo fans are familiar with Ox-Gard, which is a similar zinc compound. Ron and I are huge advocates of treating ALL electrical connections on our cars (except of course High Voltage Ignition connections) with a suitable version of this material. You can learn more about this stuff at Ron's page here: http://www.sw-em.com/anti_corrosive_paste.htm |

|

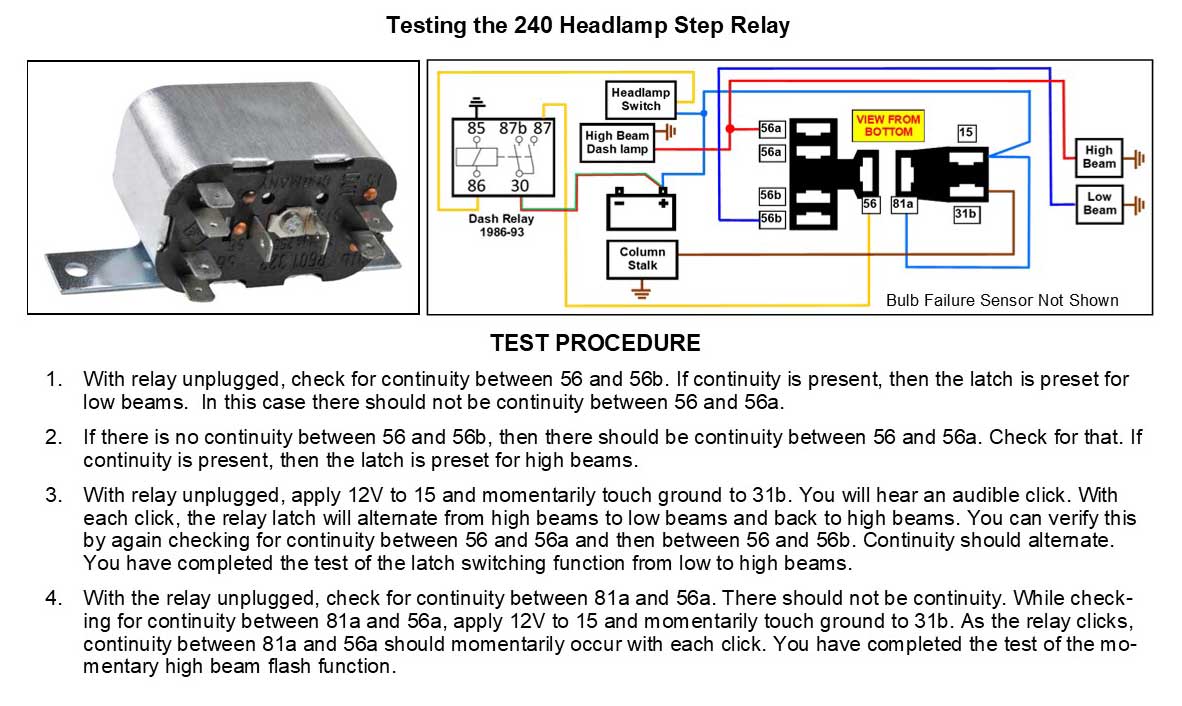

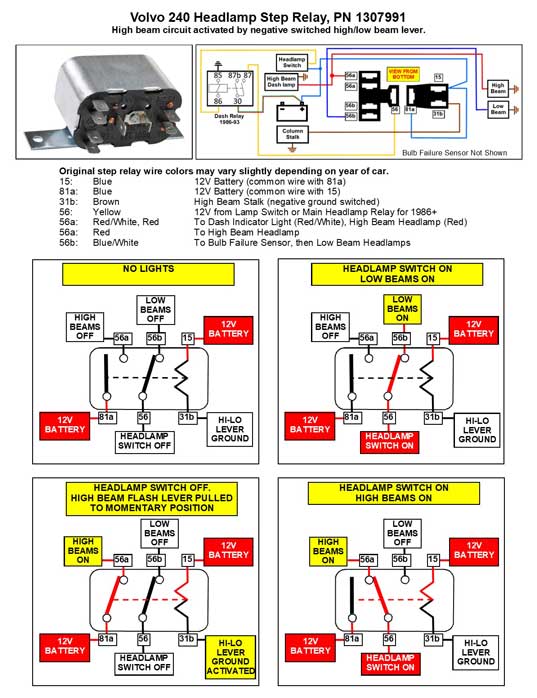

Unlocking

the Mysteries of the Volvo 240 Headlight Step Relay.

And Test Procedure. VOLVO PN 1307991.

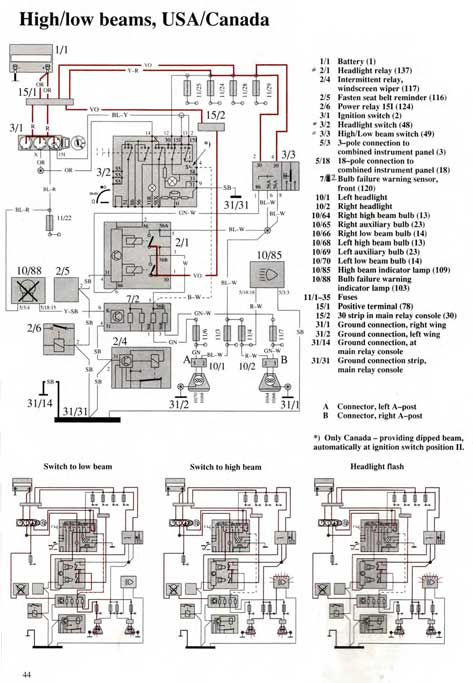

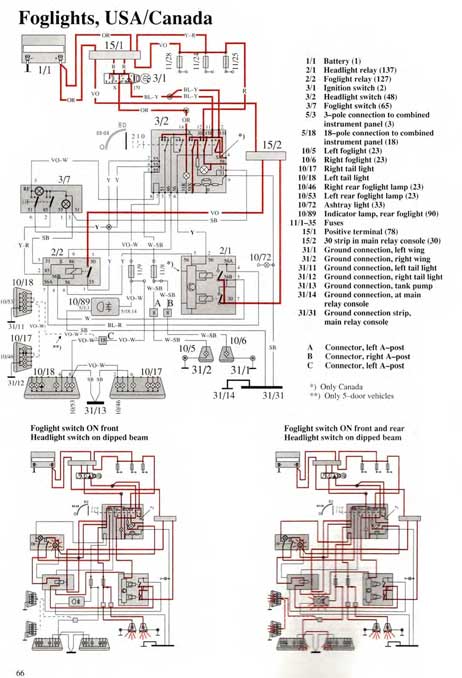

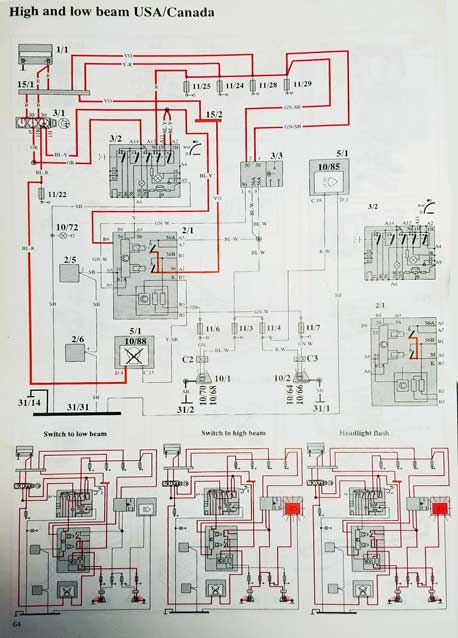

This step relay is found in the Volvo 240 from 1975 to 1993. It will be seen under your hood on the left inner fender, except for the 1993 model, where it was switched to the RIGHT inner fender.

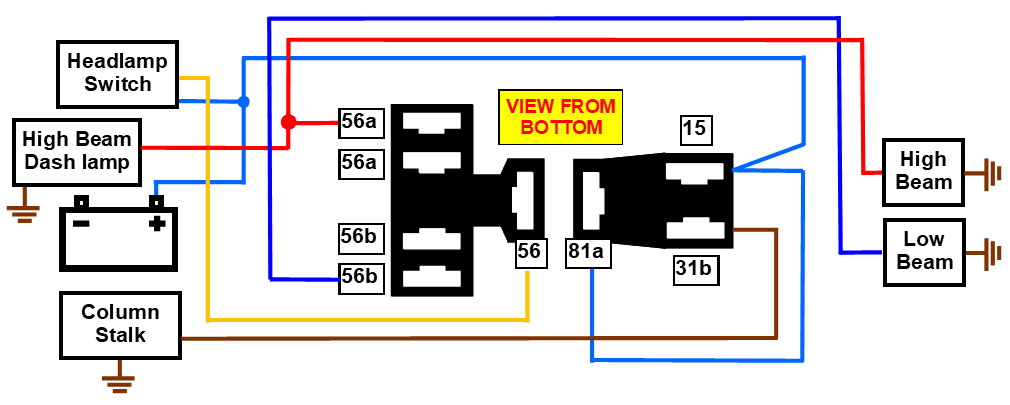

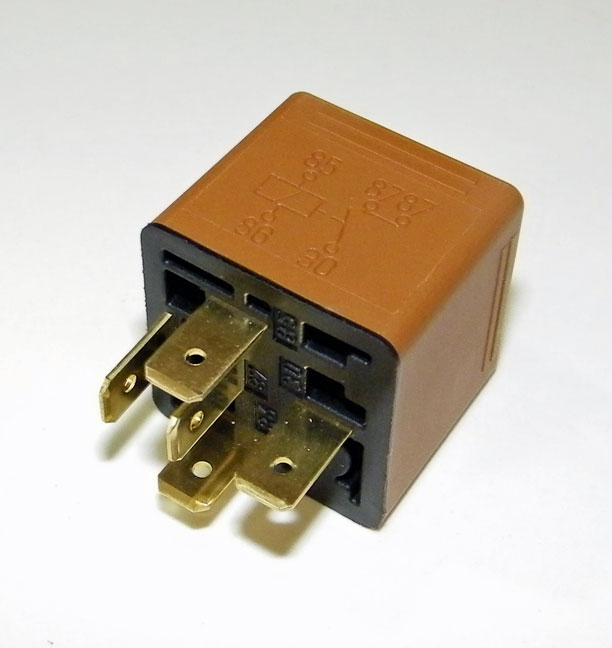

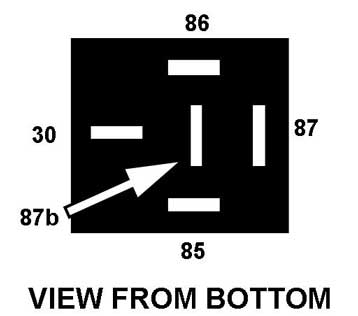

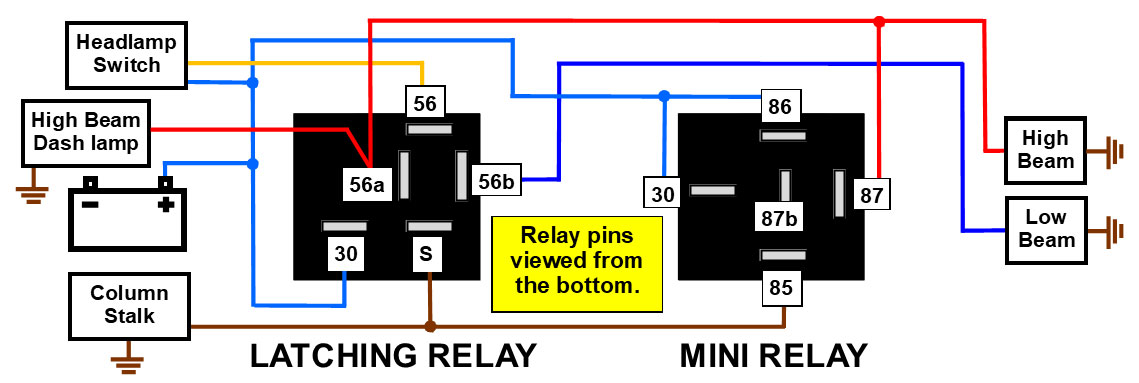

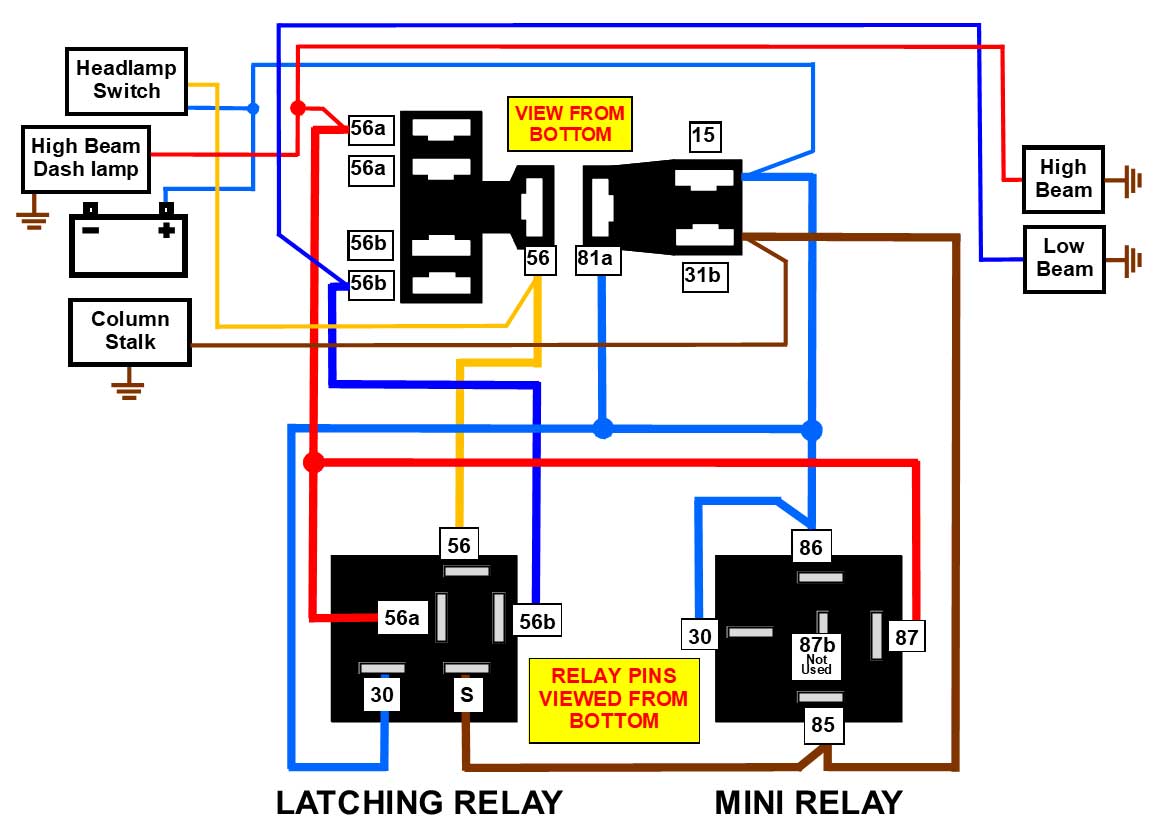

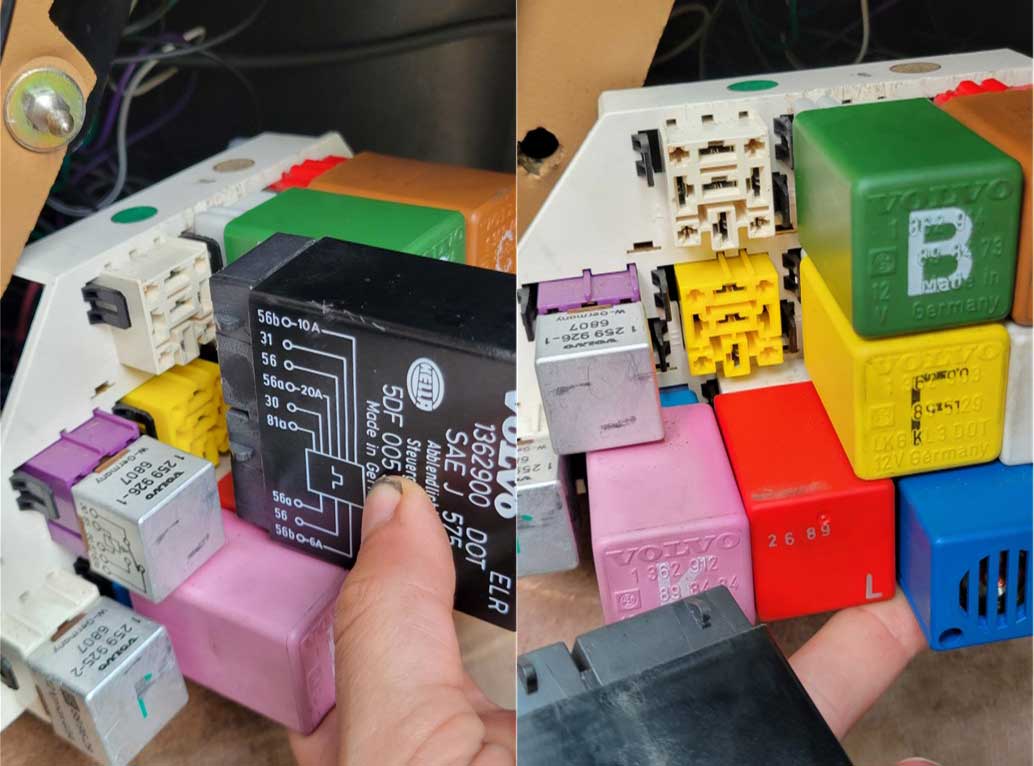

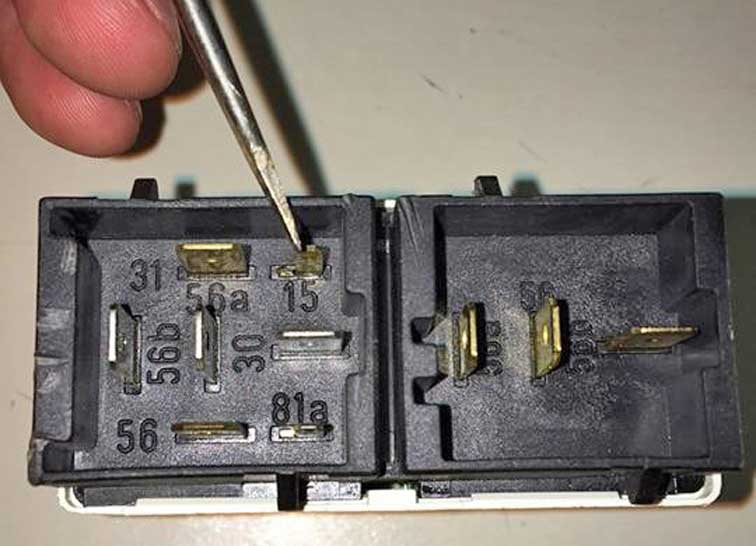

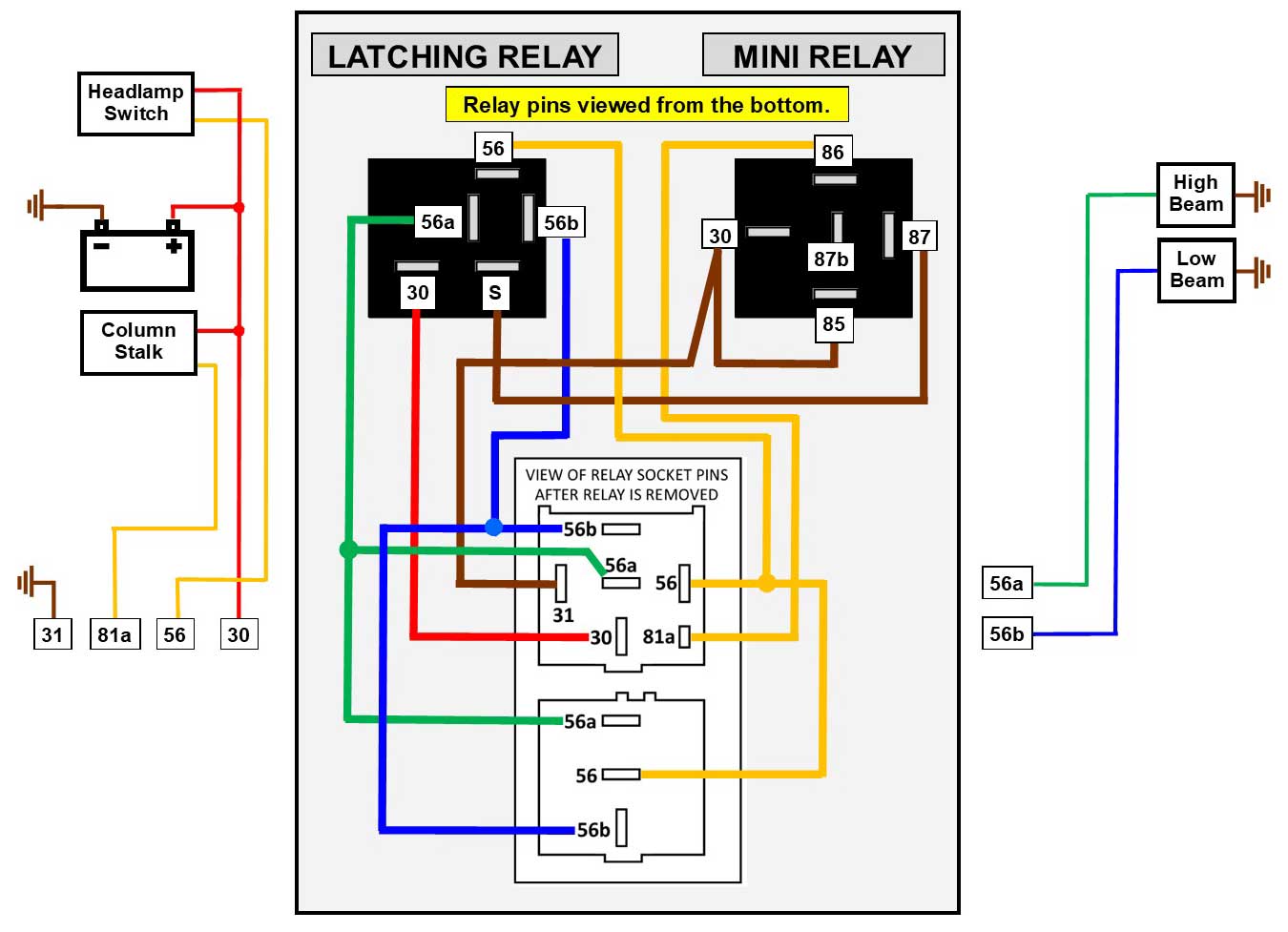

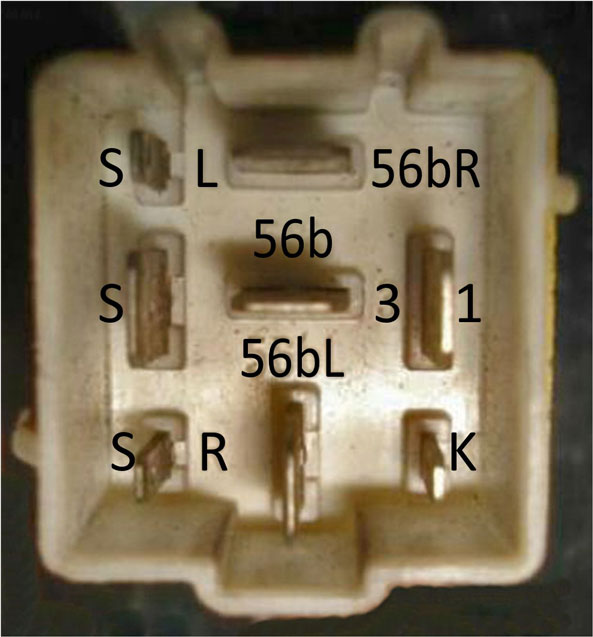

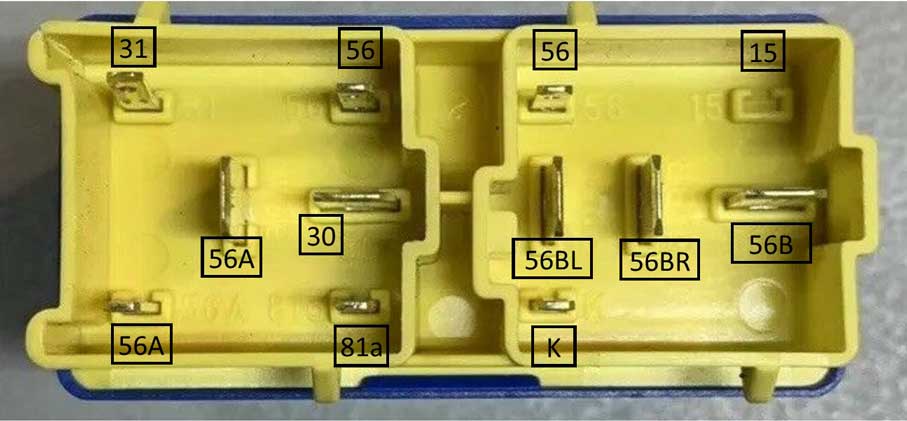

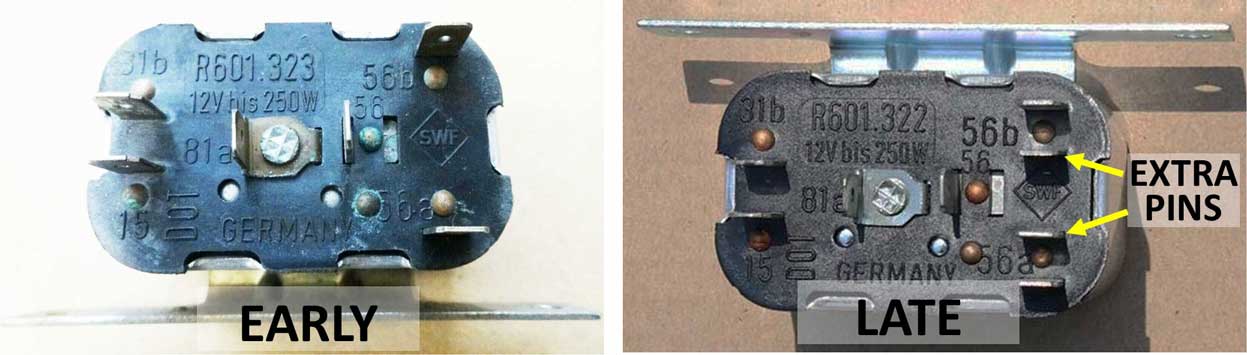

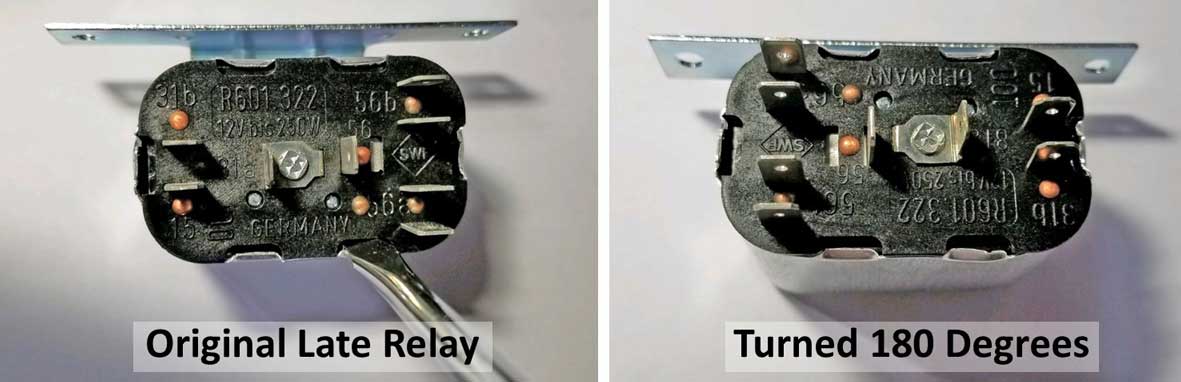

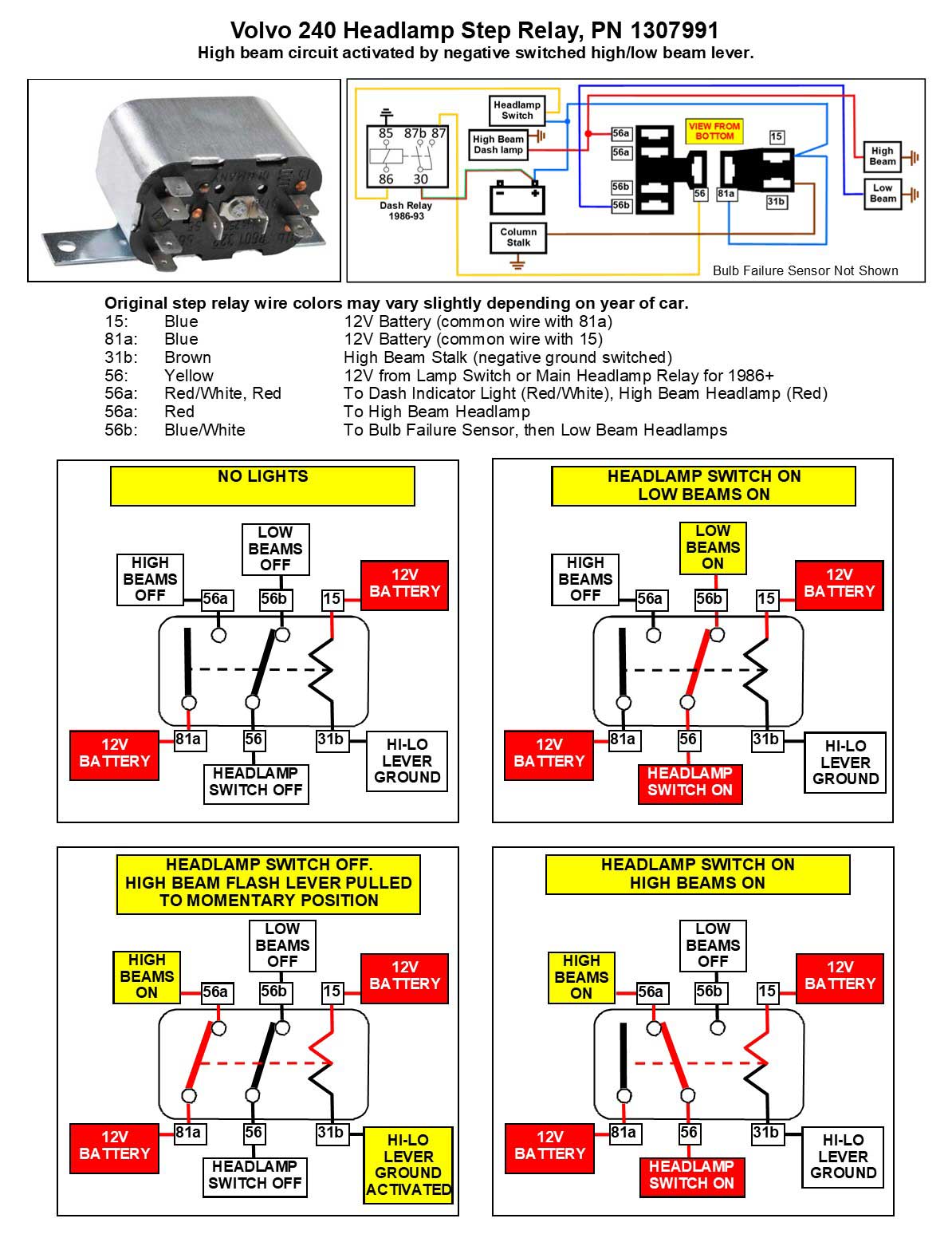

This relay was made in two different versions (same part number), however both versions function exactly the same and both are interchangeable. The EARLY version can be identified below with two less contacts. The extra contacts in the LATER version do not change the function at all. It just adds redundant contacts.  Regarding these early or later relays being interchangeable, THEY ARE, however keep in mind that if you use an early relay on a later car AND your car just happens to use those extra two contact pins, you'll need to re-wire those contact pins to the two outside pins. MOUNTING BRACKET CHANGE If you're observant, you'll notice that the mounting bracket on a later relay is on the OPPOSITE SIDE. This doesn't affect the function, but it might affect the harness plugs, because if you use a newer relay in an older car, the harness plugs will need to be twisted 180 degrees to work. That will add unwelcome stress on your wires. A simple solution is shown below.  It's a very simple task to pry open the crimps and remove the top outer housing. This is NOT hard to do. Then the housing can be turned 180 degrees and re-installed onto the relay bottom. This literally takes 30 seconds. Step Relay Latching Function Explained This step relay has a LATCHING function. A latching function works like this: You can click and release a momentary button or switch (in this case it's pulling back on the 240 high/low beam lever) and the relay will then LATCH (or lock) in one position or another. It reverses with each pull of the lever. So with this step relay, one click latches "ON" the low beams. And another click latches "OFF" the low beams and latches "ON" the high beams. In a 240 the latch function is activated by a GROUND signal, which is created by pulling the high/low beam lever. Here's a short video on the step function between high and low beam.

240 Step Relay Function and Testing

I have created the below PDF if needed (same info as shown above). https://www.davebarton.com/pdf/headlightsteprelay.pdf

|

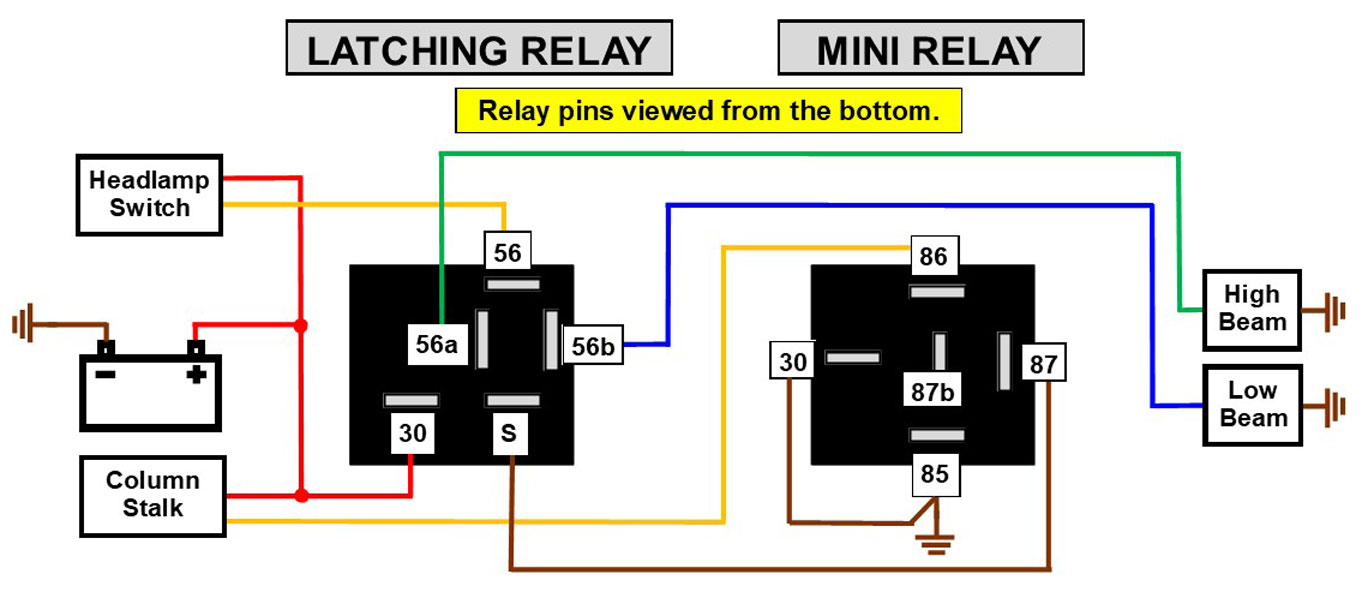

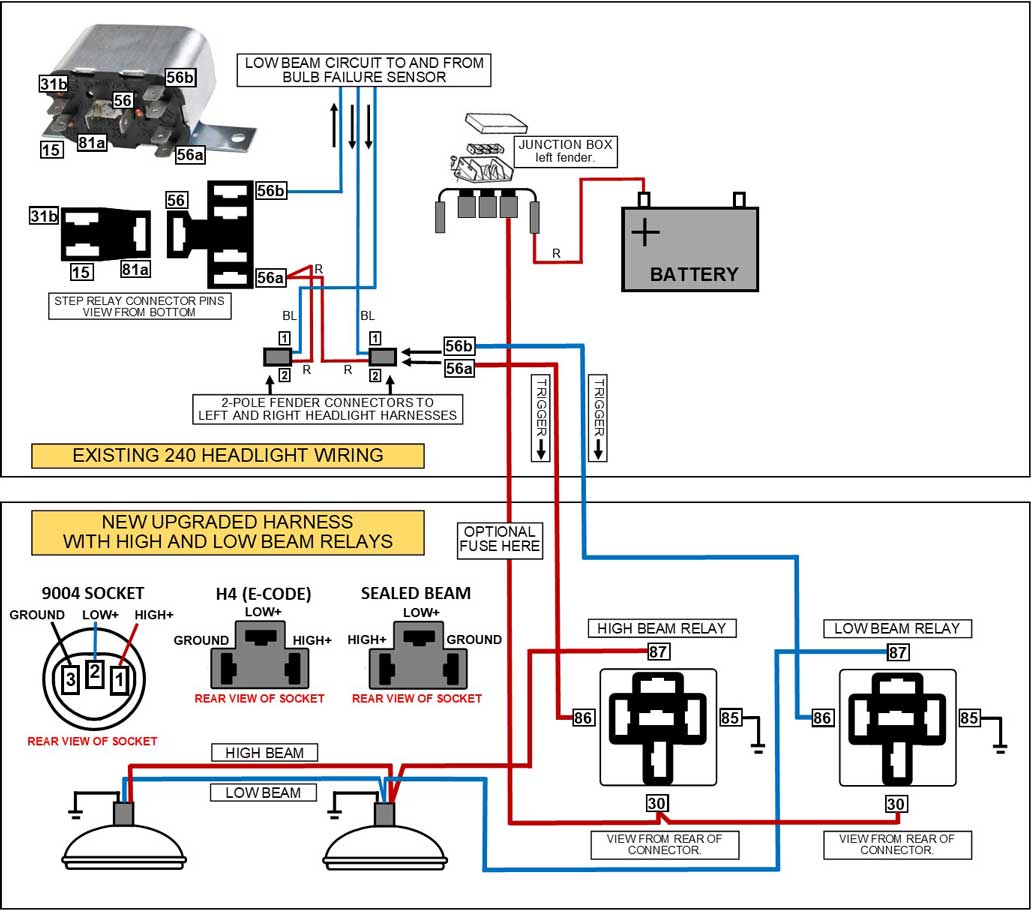

| How to Use

Commonly Available Relays to ELIMINATE or REPLICATE your Volvo 240 Headlight Step Relay. This modification will accurately reproduce the functions of the original Volvo step relay. It simply copies and can replace the Volvo step relay and connectors. It does not eliminate any need or recommendation you may have for additional headlight relays to feed high current headlights if you have them. Feel free to add those if needed.

CONTACT |

|||||||||||||||||||||||||||||||||||||||||||||||||

This

is a good project for anyone with any older Volvo, especially if you

have or want to to upgrade to brighter bulbs or headlights.

For the best info I know, begin reading Daniel Stern's page on this subject. He also has several useful diagrams for designing and building your own relay harness. http://www.danielsternlighting.com/tech/relays/relays.html Here is a Volvo 240 specific diagram showing how an upgraded relay harness can be made. The relay triggers (relay are connected to and triggered by 56a and 56b) can be taken from the fender harness connectors or if you want to bypass the bulb failure relay, you could take those triggers from terminals 56a and 56b directly from the 5-pole headlight step relay connector.  This diagram assumes you would use one relay to control both low beam headlights and another relay for the high beams. The above 9004 bulb socket came on all 1986-93 USA 240s. A European E-Code headlight will typically use an H4 bulb. UPDATE 2018: Wagonmeister is offering ready made 240 headlight relay harnesses, like this one below. |

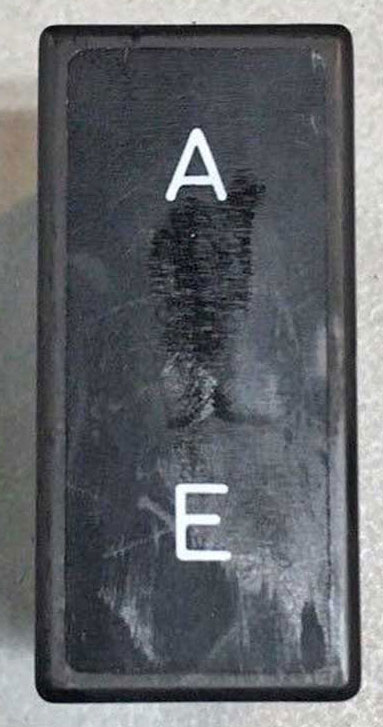

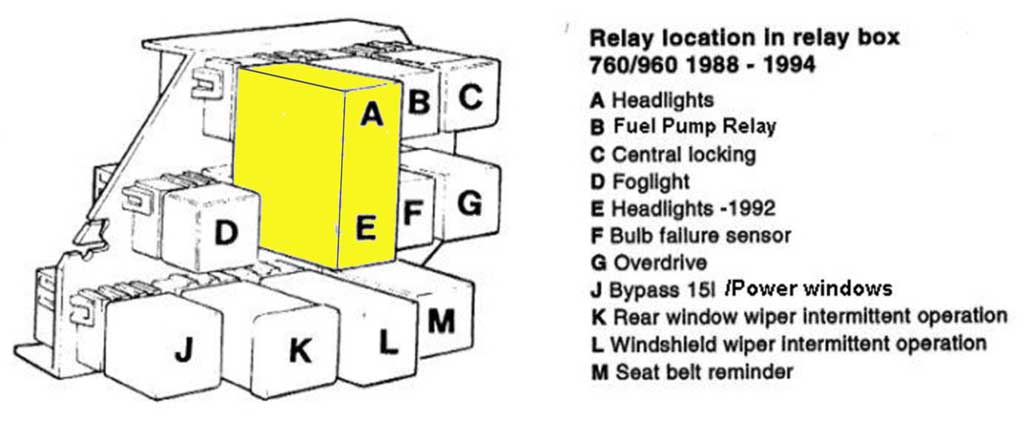

This "A-E" relay is PN 1362900 and has been no longer available new for many years. Used relays like this one have been known to show up online for OVER $200! My goal was to work out a similar solution to offer a way to ELIMINATE THIS RELAY in a similar way as the 240 step relay can be eliminated.

|

| Bosch Terminal Designations |

If you've ever wondered where all of those relay and component terminal numbers came from, they were standardized by Bosch and a list of those numbers and their meanings can be found at the following link:

http://dastern.torque.net/techdocs/boschterm.html